A kind of electrolytic solution for aluminum electrolytic capacitor with high water system and high stability and preparation method thereof

An aluminum electrolytic capacitor, high stability technology, applied in the field of electrolyte, can solve the problems of high product impedance, high cost, easy-to-heat solvent, etc., to improve safety performance and service life, good electrochemical characteristics, convenient operation and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

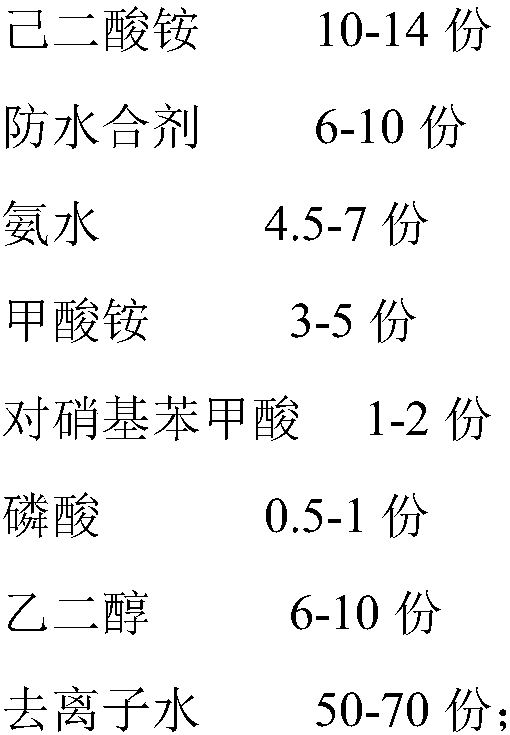

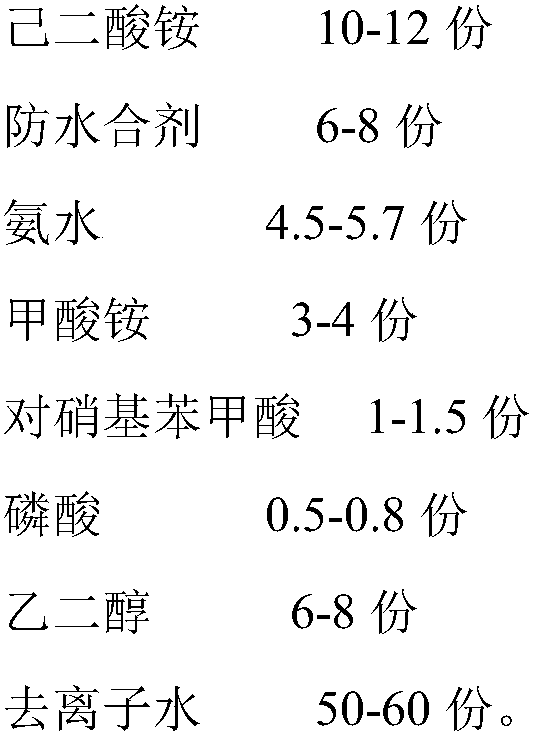

[0087] An electrolytic solution for an aluminum electrolytic capacitor with high water system and high stability, which is composed of the following raw materials in parts by weight:

[0088] Ammonium adipate 10 parts

[0089] Waterproof mixture 6 parts

[0090] Ammonia 4.5 parts

[0091] Ammonium formate 3 parts

[0092] 1 part p-nitrobenzoic acid

[0093] Phosphoric acid 0.5 part

[0094] 6 parts of ethylene glycol

[0095] 50 parts of deionized water.

[0096] The waterproofing agent is prepared by esterifying ethylene glycol, hydroxycarboxylic acid and phosphide at a weight ratio of 5:1.5:1 at a temperature of 120° C. for 4 hours.

[0097] The mass fraction of the ammonia water is 20%; the mass fraction of the phosphoric acid is 80%.

[0098] A method for preparing an electrolytic solution for an aluminum electrolytic capacitor with high water system and high stability, comprising the steps of:

[0099] (1) Weigh ammonium adipate, waterproof mixture, ammonia water,...

Embodiment 2

[0104] An electrolytic solution for an aluminum electrolytic capacitor with high water system and high stability, which is composed of the following raw materials in parts by weight:

[0105] Ammonium adipate 11 parts

[0106] Waterproof mixture 7 parts

[0107] Ammonia 5 parts

[0108] 3.5 parts of ammonium formate

[0109] 1.2 parts of p-nitrobenzoic acid

[0110] Phosphoric acid 0.7 part

[0111] Ethylene glycol 7 parts

[0112] 55 parts of deionized water.

[0113] The waterproof hydration agent is prepared by esterifying ethylene glycol, hydroxycarboxylic acid and phosphide at a weight ratio of 5.5:1.8:1 at a temperature of 130° C. for 3.5 hours.

[0114] The mass fraction of the ammonia water is 22%; the mass fraction of the phosphoric acid is 82%.

[0115] A method for preparing an electrolytic solution for an aluminum electrolytic capacitor with high water system and high stability, comprising the steps of:

[0116] (1) Weigh ammonium adipate, waterproof mixtur...

Embodiment 3

[0121] An electrolytic solution for an aluminum electrolytic capacitor with high water system and high stability, which is composed of the following raw materials in parts by weight:

[0122] Ammonium adipate 12 parts

[0123] Waterproof mixture 8 parts

[0124] Ammonia 5.7 parts

[0125] 4 parts ammonium formate

[0126] 1.5 parts of p-nitrobenzoic acid

[0127] Phosphoric acid 0.8 part

[0128] 6 parts of ethylene glycol

[0129] 60 parts of deionized water.

[0130] The waterproof hydrating agent is prepared by esterifying ethylene glycol, hydroxycarboxylic acid and phosphide at a weight ratio of 6:2:1 at a temperature of 145° C. for 3.5 hours.

[0131] The mass fraction of the ammonia water is 25%; the mass fraction of the phosphoric acid is 85%.

[0132] A method for preparing an electrolytic solution for an aluminum electrolytic capacitor with high water system and high stability, comprising the steps of:

[0133] (1) Weigh ammonium adipate, waterproof mixture, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com