Naphthol-derivative quaternary ammonium salt cationic surface active agent and preparing method thereof

A technology for quaternary ammonium salt cations and surfactants, which is applied in the field of quaternary ammonium salt cationic surfactants and their preparation, can solve the problems of low surface activity and high critical micelle concentration, and achieve simple preparation methods and lower critical micelle concentration , the effect of high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

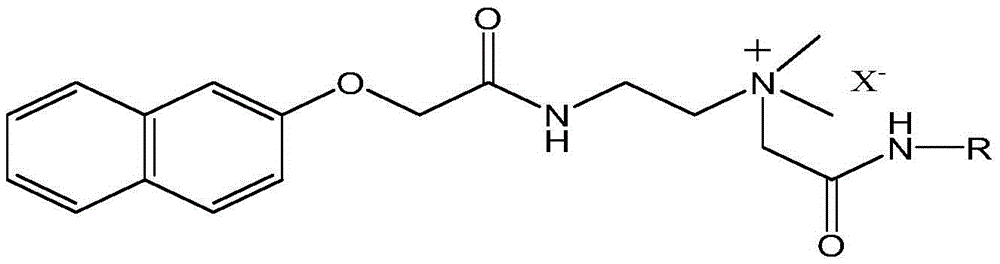

[0022] Specific embodiment one: the chemical name of the naphthol derivative quaternary ammonium salt cationic surfactant of the present embodiment is N-alkylacylmethyl-N-[2-(2-naphthyloxyacetyl)-ethyl] -N,N-Dimethylammonium halide, its structural formula is:

[0023]

[0024] where R=C n h 2n+1 , n=8~22, X is a halogen.

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that n=12-18. Others are the same as method one.

specific Embodiment approach 3

[0026] Specific embodiment three: the preparation method of the naphthol derivative quaternary ammonium salt cationic surfactant described in specific embodiment one, carry out according to the following steps:

[0027] 1. Add the solvent I into the container, and then press the molar ratio of N-acetyl-(2-ethylnaphthyloxy)-N,N-dimethylethylenediamine and haloacetylalkylamine to be 1:(1 ~6) Add N-acetyl-(2-ethylenenaphthyloxy)-N,N-dimethylethylenediamine and haloacetylalkylamine, raise the temperature to 100℃~150℃ and stir for 24h~48h to obtain crude product;

[0028] 2. The crude product obtained in step 1 is rotary evaporated to obtain a viscous paste;

[0029] 3. Use solvent II to recrystallize the viscous paste to obtain a white solid, namely the naphthol derivative quaternary ammonium salt cationic surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com