Aminated poly-glycidyl methacrylate crosslinked composite microsphere and preparation method as well as application thereof

A polymethacrylic acid, glycidyl ester technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry and other directions, can solve the problems of difficult control of suspension polymerization process conditions, unstable product properties, etc., and is conducive to large-scale production. Application, macroscopically controllable size, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

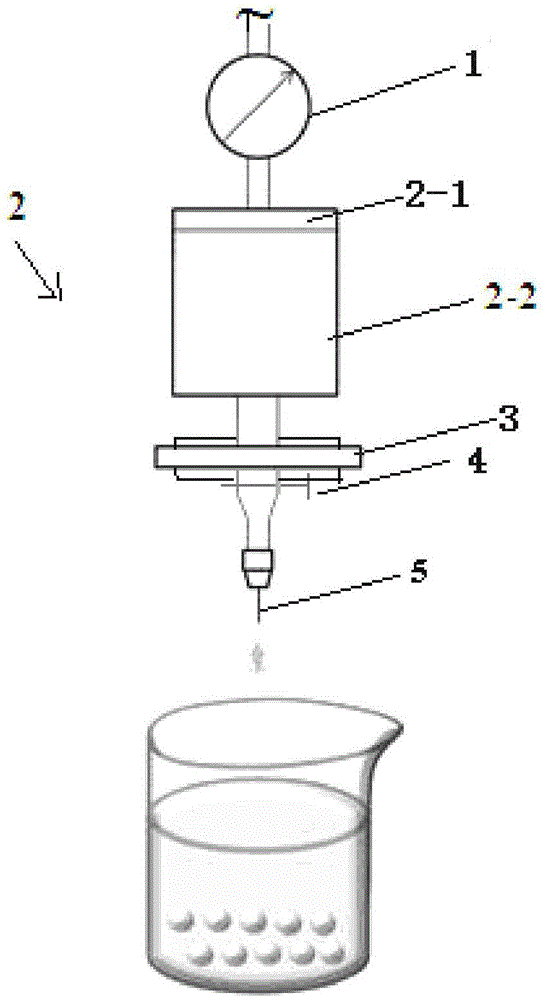

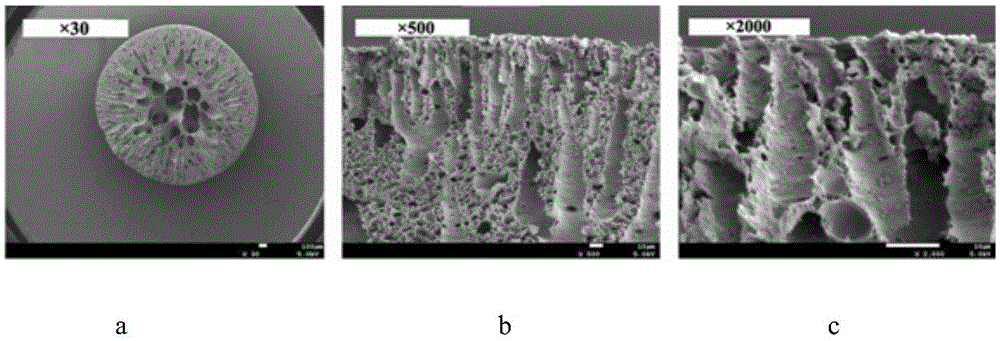

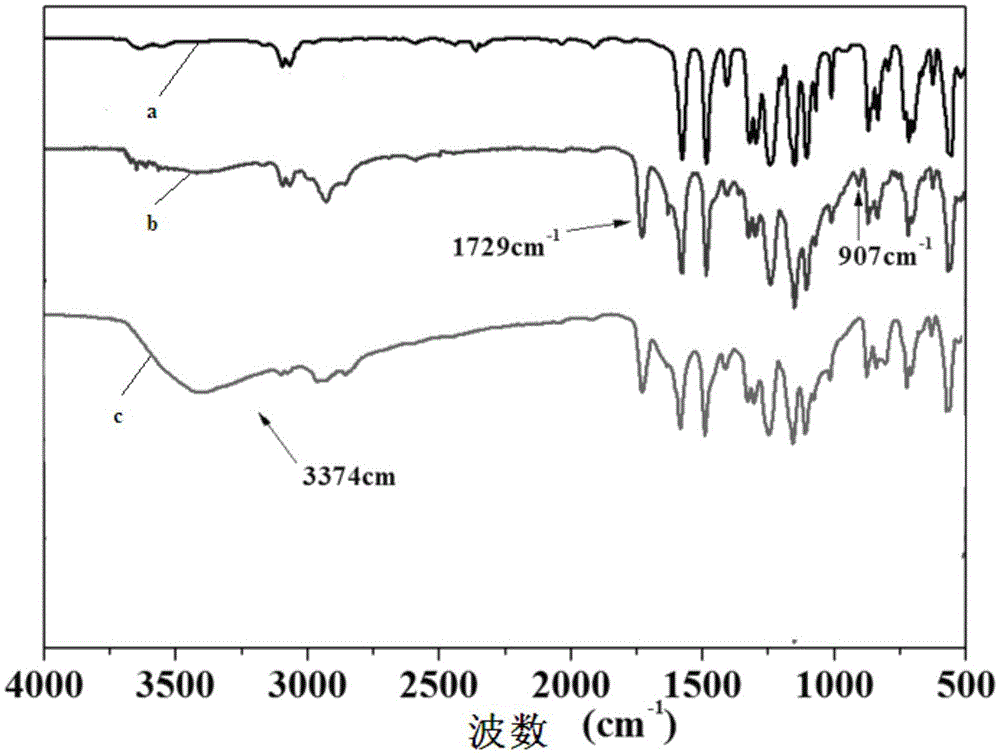

[0040] In this embodiment, the preparation method of aminated polyglycidyl methacrylate crosslinked composite microspheres is as follows:

[0041] (1) Polymerization reaction

[0042] Dissolve 14 parts of polyethersulfone in 86 parts of N,N-dimethylacetamide, heat to 90°C and stir to completely dissolve the polyethersulfone to obtain a polyethersulfone solution, and add methyl Glycidyl acrylate, cross-linking agent N, N'-methylenebisacrylamide and initiator azobisisobutyronitrile, after vacuuming to remove oxygen, nitrogen gas was introduced, and the reaction was stirred under nitrogen protection at 90°C for 24 hours. Stop heating and stirring after the reaction is over, place the reaction solution gained from the reaction for 24 hours and then filter to obtain a filtrate. The resulting filtrate is the preparation solution of polyglycidyl methacrylate crosslinked composite microspheres. Nitrogen gas is passed into the preparation solution of combined composite microspheres fo...

Embodiment 2

[0050] In this embodiment, the preparation method of aminated polyglycidyl methacrylate crosslinked composite microspheres is as follows:

[0051] (1) Polymerization reaction

[0052] Dissolve 10 parts of polyethersulfone in 90 parts of N,N-dimethylacetamide, heat to 60°C and stir to completely dissolve the polyethersulfone to obtain a polyethersulfone solution, and add methyl Glycidyl acrylate, cross-linking agent N, N'-methylenebisacrylamide and initiator azobisisobutyronitrile, after vacuuming to remove oxygen, nitrogen gas was introduced, and the reaction was stirred under nitrogen protection at 60°C for 18 hours. Stop heating and stirring after the reaction is over, place the reaction solution gained from the reaction for 24 hours and then filter to obtain a filtrate. The resulting filtrate is the preparation solution of polyglycidyl methacrylate crosslinked composite microspheres. Nitrogen gas is passed into the preparation solution of combined composite microspheres fo...

Embodiment 3

[0059] In this embodiment, the preparation method of aminated polyglycidyl methacrylate crosslinked composite microspheres is as follows:

[0060] (1) Polymerization reaction

[0061] Dissolve 12 parts of polystyrene in 88 parts of N,N-dimethylacetamide, heat to 60°C and stir to completely dissolve the polystyrene to obtain a polystyrene solution, and add methyl Glycidyl acrylate, cross-linking agent N, N'-methylenebisacrylamide and initiator azobisisobutyronitrile, after vacuuming to remove oxygen, nitrogen gas was introduced, and the reaction was stirred under nitrogen protection at 60°C for 18 hours. Stop heating and stirring after the reaction is over, place the reaction solution obtained from the reaction for 24 hours and then filter to obtain the filtrate, which is the preparation solution of polyglycidyl methacrylate crosslinked composite microspheres;

[0062] When forming the reaction system, the addition of glycidyl methacrylate is 6 parts; the molar ratio of crossl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com