Preparing method of multilayer composite high polymer packaging material

A packaging material, multi-layer composite technology, applied in the field of food packaging materials, can solve the problems of reduced performance, performance impact, unsatisfactory EVOH processing performance, etc., to achieve the effect of excellent gas and enhanced blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

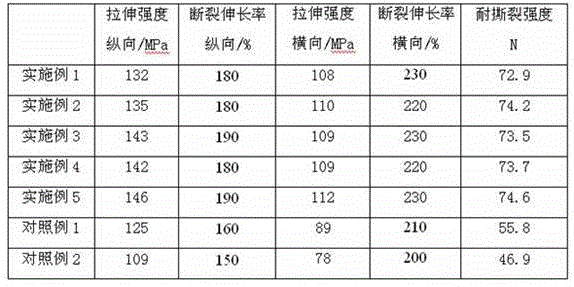

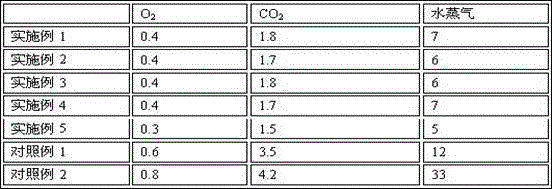

Examples

Embodiment 1

[0036] The 1st step, the preparation of modified PET: get polyethylene terephthalate 120g, polybutylene terephthalate 50g, polypropylene 80g, isobutyl methacrylate 2g, polycarbonate 5g and Put 10 g of ethylene-vinyl acetate copolymer into a rheometer, melt and blend at 265 ° C, and cool to obtain modified PET;

[0037] Step 2, preparation of modified PP: take 200g of polypropylene, 15g of nano-titanium oxide, 13 parts of glass fiber, 40g of polyolefin elastomer, PP-g-MAH60g, 15g of polyacrylate, 4g of ethylene-vinyl acetate copolymer and 15g of polyamide was mixed in an internal mixer at 148°C for 3min10s to obtain modified PP;

[0038] Step 3. Preparation of modified EVOH: Take 200g of EVOH, 150g of PP-g-MAH and 20g of polyacrylic acid, put them into an internal mixer for internal mixing, the temperature of internal mixer is 210°C, and the internal mixing time is 3min50s to obtain modified EVOH;

[0039] Step 4. Put the modified PET, modified PP and modified EVOH into the ex...

Embodiment 2

[0042] The 1st step, the preparation of modified PET: get polyethylene terephthalate 170g, polybutylene terephthalate 100g, polypropylene 150g, isobutyl methacrylate 8g, polycarbonate 15g and Put 30 g of ethylene-vinyl acetate copolymer into a rheometer, melt and blend at 265 ° C, and cool to obtain modified PET;

[0043] Step 2, preparation of modified PP: take 200g of polypropylene, 15g of nano-titanium oxide, 13 parts of glass fiber, 40g of polyolefin elastomer, PP-g-MAH60g, 15g of polyacrylate, 4g of ethylene-vinyl acetate copolymer and 15g of polyamide was mixed in an internal mixer at 148°C for 3min10s to obtain modified PP;

[0044]Step 3. Preparation of modified EVOH: Take 400g of EVOH, 250g of PP-g-MAH and 50g of polyacrylic acid, put them into an internal mixer for internal mixing, the temperature of internal mixer is 210°C, and the internal mixing time is 3min50s to obtain modified EVOH;

[0045] Step 4. Put the modified PET, modified PP and modified EVOH into the ...

Embodiment 3

[0048] The 1st step, the preparation of modified PET: get polyethylene terephthalate 140g, polybutylene terephthalate 70g, polypropylene 120g, isobutyl methacrylate 5g, polycarbonate 11g and Put 21g of ethylene-vinyl acetate copolymer into a rheometer, melt and blend at 265°C, and cool to obtain modified PET;

[0049] Step 2, preparation of modified PP: Take 150g of polypropylene, 10g of nano-titanium oxide, 10g of glass fiber, 30g of polyolefin elastomer, 30g of PP-g-MAH, 10g of polyacrylate, 20g of ethylene-vinyl acetate copolymer and poly Put 10g of amide into the internal mixer and knead at 148°C for 3min10s to obtain modified PP;

[0050] Step 3. Preparation of modified EVOH: Take 320g of EVOH, 240g of PP-g-MAH and 30g of polyacrylic acid, put them into an internal mixer for internal mixing, the temperature of internal mixer is 210°C, and the internal mixing time is 3min50s to obtain modified EVOH;

[0051] Step 4. Put the modified PET, modified PP and modified EVOH into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com