A kind of preparation method and application of graphene oxide framework material self-assembled film

A technology of graphene skeleton and self-assembled membrane, which is applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of expensive equipment, high energy consumption, complicated operation, etc., and achieve adjustable screening channels and membrane thickness, high Density and mechanical strength, effect of enhancing bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

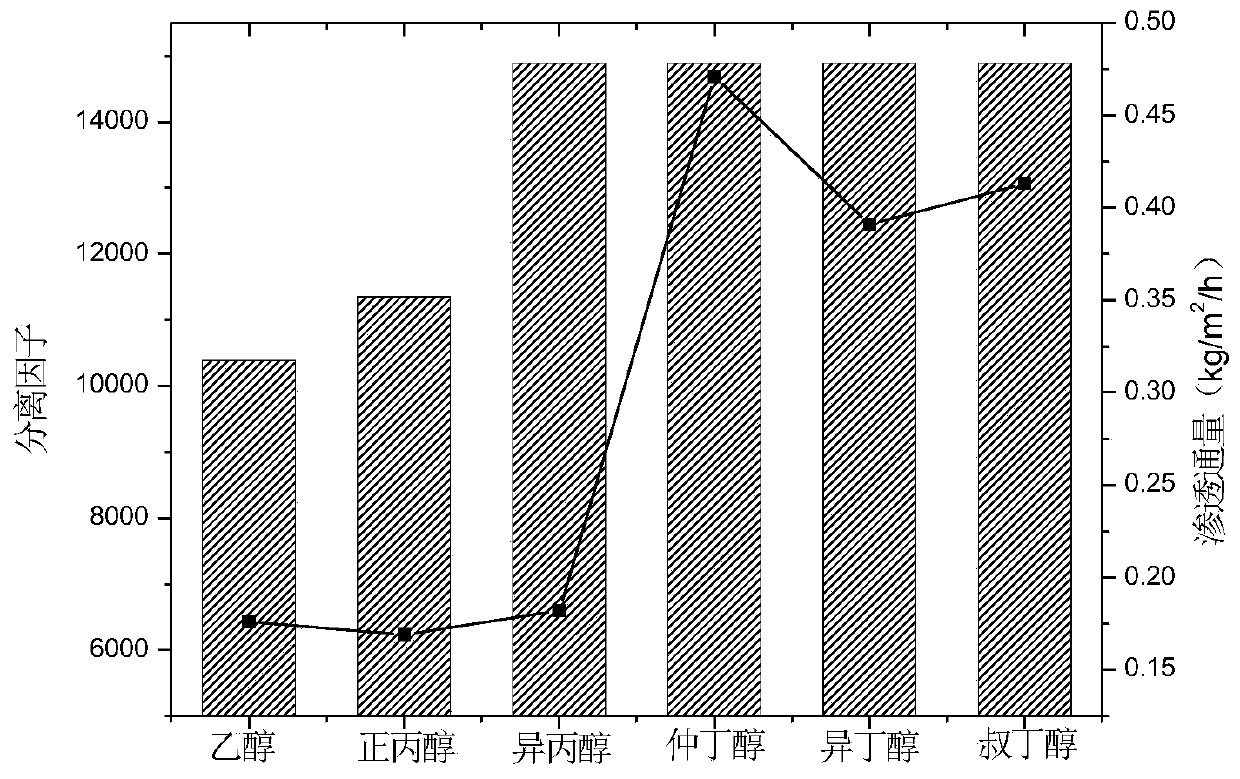

[0043] Example 1: A self-assembled membrane of graphene oxide framework material was prepared on a tubular ceramic carrier for the separation of water and a mixture of C2-C4 alcohols and their isomers.

[0044] Step 1: Select a porous ceramic tube as the carrier. The inner and outer diameters of the porous ceramic tube are 10mm and 7mm respectively, the average pore diameter of the inner surface is 100nm, both ends of the carrier are glazed, and the effective membrane length is 3-5mm. After washing and drying, bake at 500°C for 1h. The outer surface is sealed with PTFE tape.

[0045] Step 2: Charge modification of alumina support: Add 0.2g of 3-aminopropyltrimethoxysilane to 100ml of toluene solution, put into 100nmAl 2 o 3 Porous ceramic support, solvothermal reaction at 110°C for 1h. After taking it out, it was dried in a vacuum oven at 50°C for 12 hours.

[0046] Step 3: Add 100 mg of graphene oxide into 50 ml of water, and use a sonicator to prepare a 2 mg / g graphene o...

Embodiment 2

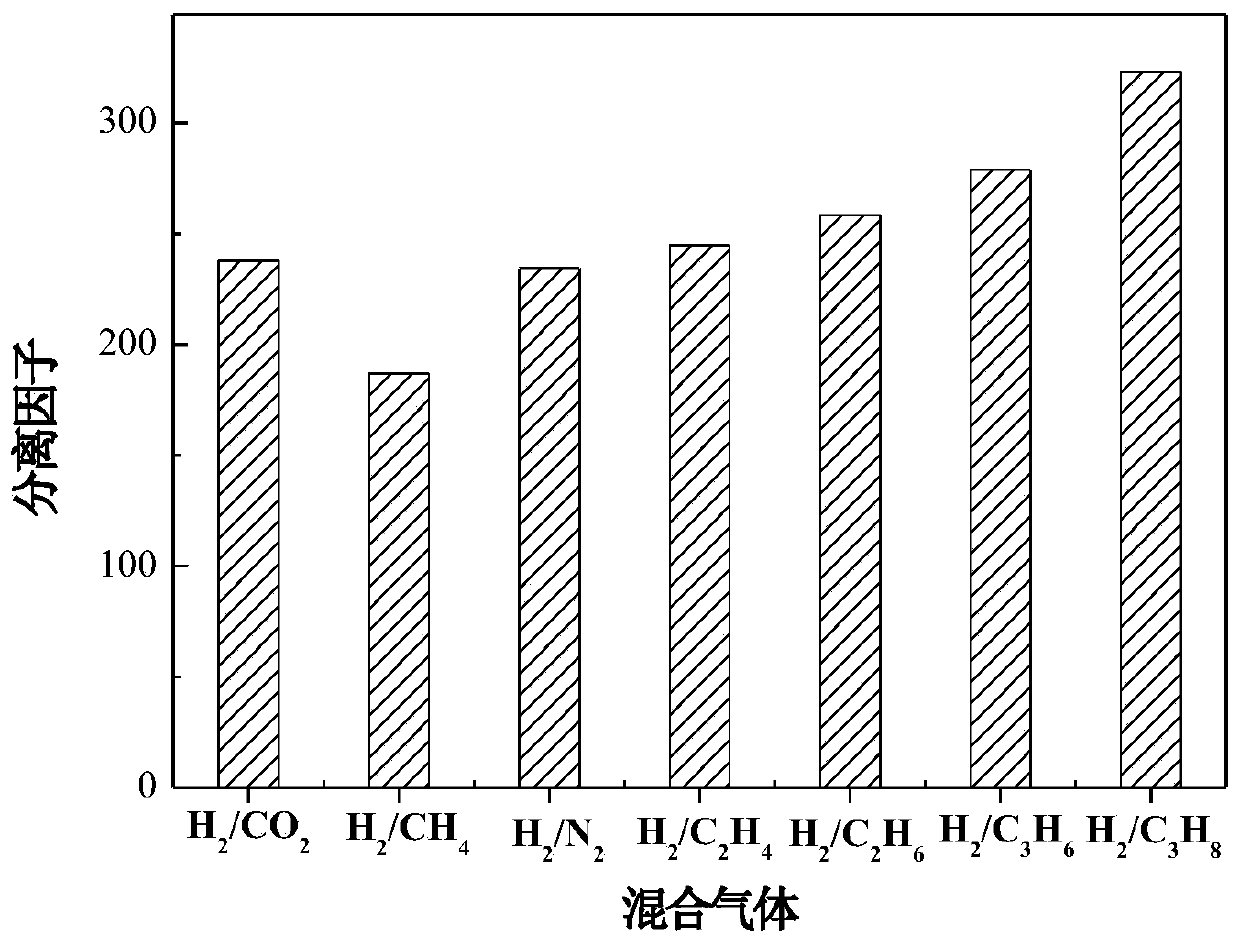

[0055] Embodiment 2: Prepare graphene oxide skeleton material self-assembled film on tubular ceramic carrier, be used for testing single-component gas such as H 2 , N 2 , CO 2 、CH 4 、C 2 h 4 、C 2 h 6 、C 3 h 6 、C 3 h 8 The permeate flux and its separation selectivity.

[0056] The difference from Example 1 is that in step 5, the system to be separated is a single-component gas. The temperature is normal temperature, the pressure test range is 0.2-1bar, and the permeation rate is P(mol / m2 / s / Pa).

[0057] Separation selectivity α=PX / PH 2 . Where X stands for N 2 , CO 2 , CH 4 , C 2 h 4 , C 2 h 6 , C 3 h 6 , C 3 h 8 gas.

[0058] Various single-component gas permeation rates of table 2 embodiment 2 and the separation selectivity with hydrogen

[0059]

[0060]

[0061] attached figure 2 It is the separation selectivity comparison of various single-component gases and hydrogen in this embodiment. From Table 2 and figure 2 It can be seen from the...

Embodiment 3

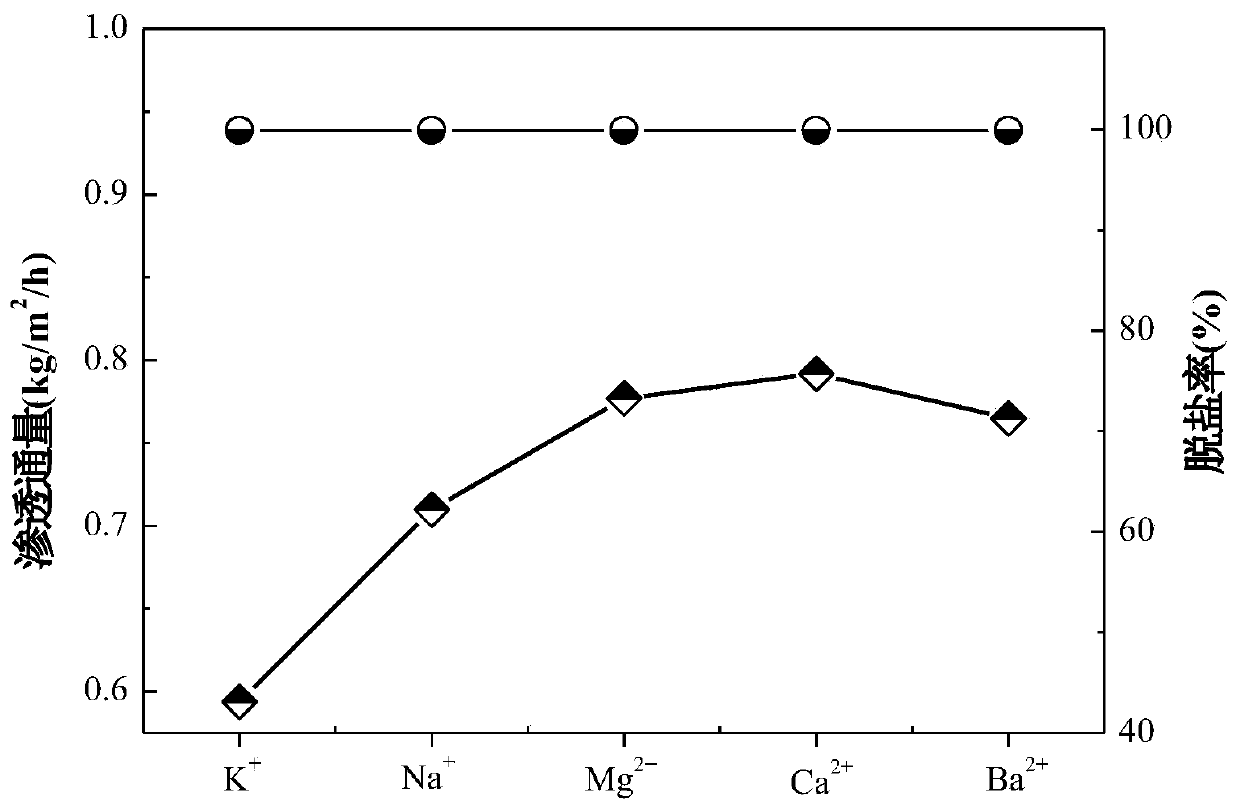

[0062] Example 3: Preparation of graphene oxide framework material self-assembled membrane on tubular ceramic carrier for separating saline solution, such as KaCL, Na 2 SO 4 , MgSO 4 , CaCl, BaCl aqueous solution.

[0063] The difference from Example 1 is that in step 5, the system to be separated is an aqueous salt solution, the operating temperature is 30-70° C., the system pressure is 0.1 MPa, and the feed mass concentration is 0.1 mol / L.

[0064] Permeate flux calculation formula: J=Δm / (s×t), where Δm is the mass of product collected on the permeate side, in kg; s is the effective membrane area, in m 2 ;t is the collection time, the unit is h.

[0065] The desalination rate is separation liquid concentration / raw material liquid concentration.

[0066] The permeation flux and desalination rate of various salt solutions of table 3 embodiment 3

[0067]

[0068] attached image 3 It is a comparison of permeation flux and desalination rate of various salt solutions in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com