Strain composition for treating VOCs containing waste gas and method for treating VOCs containing waste gas

A treatment method and composition technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, separation methods, etc., can solve the problems of low VOCs waste gas treatment efficiency, and achieve the effect of improving treatment effect and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

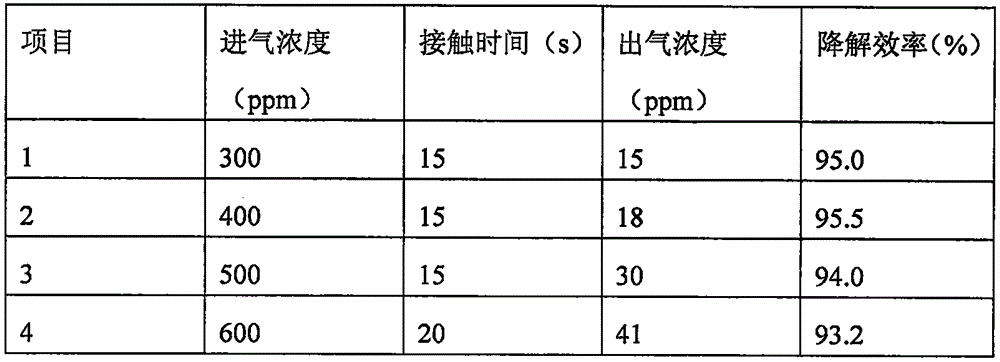

Embodiment 1

[0034] The Bacillus subtilis with the preservation number CICC10732 was added to sterilized and cooled 0.9% physiological saline, shaken and dissolved, and left to activate in an incubator for 30 minutes, and then the mass ratio was 6:2:1 of glucose, ammonium sulfate and Expand the cultivation in the medium of potassium phosphate for 15 days to obtain the Bacillus subtilis culture fluid; during the expansion cultivation process, when the oxygen content in the bacterial fluid is lower than 2.5mg / L, glucose with a mass ratio of 6:2:1 needs to be added , ammonium sulfate and potassium phosphate;

[0035] Add the Bacillus atrophaeus with the preservation number CICC23590 into sterilized and cooled 0.9% physiological saline, shake and dissolve, and place it in an incubator for 30 minutes to activate, and then in the mass ratio of 6:2:1 glucose, ammonium sulfate and Expand culture in the medium of potassium phosphate for 15 days to obtain the culture solution of Bacillus atrophaeus;...

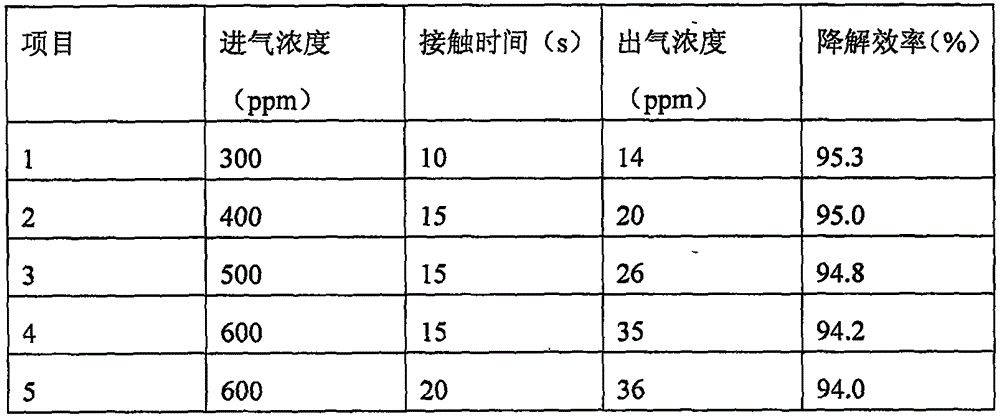

Embodiment 2

[0039]The Bacillus subtilis with the preservation number CICC10732 was added to sterilized and cooled 0.9% physiological saline, shaken and dissolved, and left to activate in an incubator for 30 minutes, and then the mass ratio was 6:2:1 of glucose, ammonium sulfate and Expand the cultivation in the medium of potassium phosphate for 15 days to obtain the Bacillus subtilis culture fluid; during the expansion cultivation process, when the oxygen content in the bacterial fluid is lower than 2.5mg / L, glucose with a mass ratio of 6:2:1 needs to be added , ammonium sulfate and potassium phosphate;

[0040] Add the Bacillus atrophaeus with the preservation number CICC23590 into sterilized and cooled 0.9% physiological saline, shake and dissolve, and place it in an incubator for 30 minutes to activate, and then in the mass ratio of 6:2:1 glucose, ammonium sulfate and Expand culture in the medium of potassium phosphate for 15 days to obtain the culture solution of Bacillus atrophaeus; ...

Embodiment 3

[0044] The Bacillus subtilis with the preservation number CICC10732 was added to sterilized and cooled 0.9% physiological saline, shaken and dissolved, and left to activate in an incubator for 30 minutes, and then the mass ratio was 6:2:1 of glucose, ammonium sulfate and Expand the cultivation in the medium of potassium phosphate for 15 days to obtain the Bacillus subtilis culture fluid; during the expansion cultivation process, when the oxygen content in the bacterial fluid is lower than 2.5mg / L, glucose with a mass ratio of 6:2:1 needs to be added , ammonium sulfate and potassium phosphate;

[0045] Add the Bacillus atrophaeus with the preservation number CICC23590 into sterilized and cooled 0.9% physiological saline, shake and dissolve, and place it in an incubator for 30 minutes to activate, and then in the mass ratio of 6:2:1 glucose, ammonium sulfate and Expand culture in the medium of potassium phosphate for 15 days to obtain the culture solution of Bacillus atrophaeus;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com