Corrosion inhibitor suitable for delivery pipeline in H2S/CO2-containing corrosive environment of oil and gas field and preparation method of corrosion inhibitor

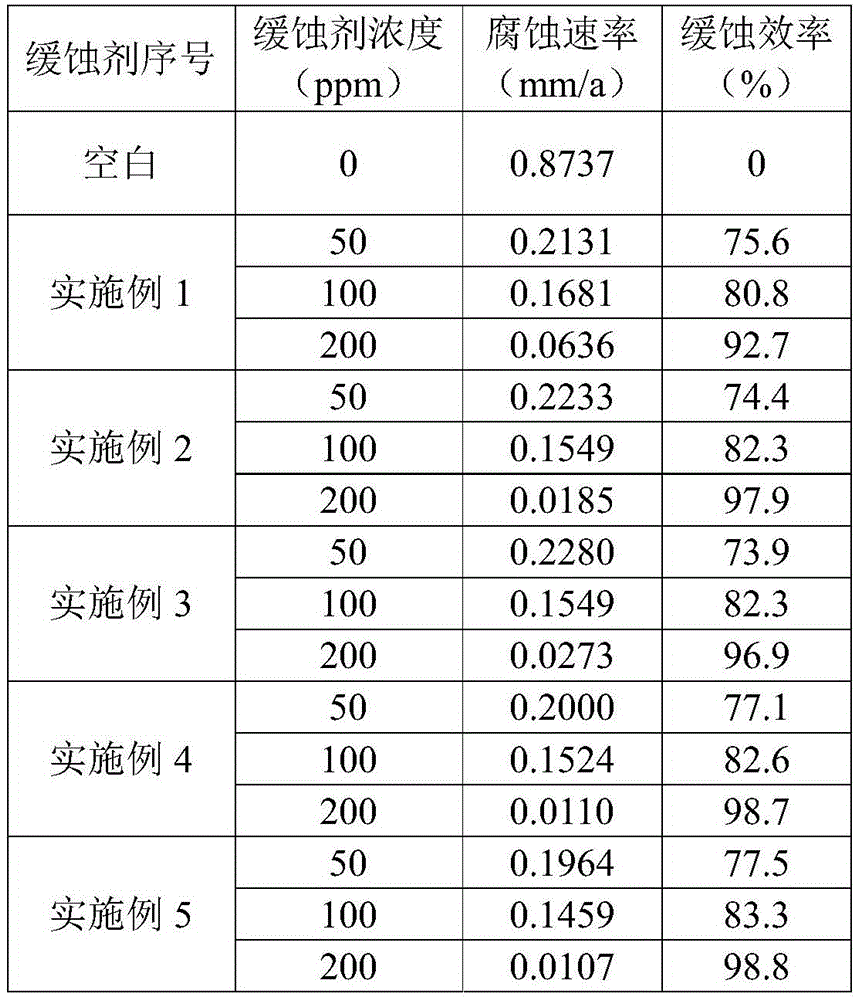

A technology for corrosive environment and transportation pipeline, which is applied in the field of corrosion inhibitor and preparation field of transportation pipeline in corrosive environment containing H2S/CO2 in oil and gas fields, can solve the problem that pipeline steel cannot achieve corrosion inhibition effect, etc. The effect of high corrosion inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] While the present invention provides the above-mentioned corrosion inhibitor formula, it also provides a kind of H2-containing corrosion inhibitor based on the above that is suitable for oil and gas fields. 2 S / CO 2 A method for preparing a corrosion inhibitor for a pipeline in a corrosive environment, the preparation method comprising the following steps:

[0021] 1) Synthesis of propynyl alcohol Mannich base quaternary ammonium salt:

[0022] 1.1) Add propynyl alcohol, benzene, and paraformaldehyde into a three-necked flask equipped with a water separator, heat up to 60°C and stir for 30 minutes, then add dodecylamine dropwise at a rate of 1-2 drops per second; After the addition, heat up to reflux temperature of 80°C and start reflux; the molar ratio of propynyl alcohol, paraformaldehyde, dodecylamine and benzene is 2:2:1:5; when the moisture separated from the anti-water separator reaches the theoretical When the amount of water or the separated moisture is consta...

Embodiment 1

[0029] 1) Synthesis of dodecylamine propynyl alcohol Mannich base quaternary ammonium salt:

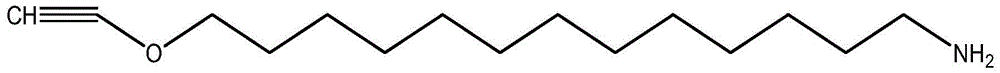

[0030] Add 100ml of solvent benzene, 33.6g of propynyl alcohol, and 18g of paraformaldehyde into a three-neck flask (equipped with a water separator), and then raise the temperature to 60°C. After reacting for 30 minutes, weigh 55.7g of dodecylamine, and use drops Slowly add amine to the liquid funnel. After the drop is completed, heat up and reflux for reaction until the water separated from the water separator reaches the theoretical water amount or when the separated water is constant, the reaction is completed. After cooling down, the solvent in the product is distilled off under reduced pressure. Benzene to give the corresponding Mannich base. Add 38g of benzyl chloride to the flask again, control the temperature at about 90°C for a constant reaction for 20-25 hours, and cool down to obtain the quaternary ammonium salt of dodecylamine propynyl alcohol Mannich base, see figure 1 ...

Embodiment 2

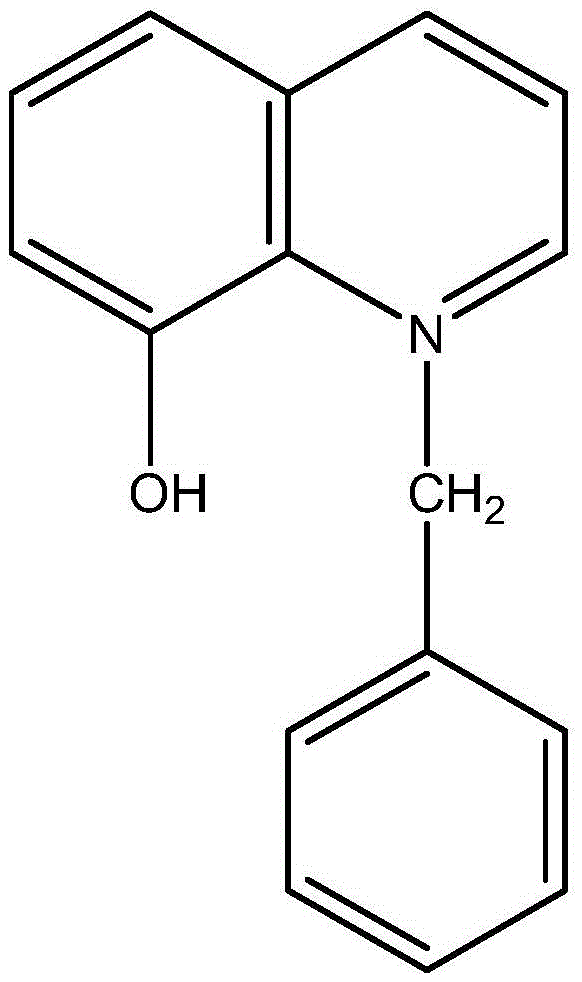

[0035] Take 25% of dodecylamine propynyl alcohol Mannich base quaternary ammonium salt by mass ratio, add 30.5% ethanol, add 19% of 8-hydroxyquinoline quaternary ammonium salt after stirring, add fatty alcohol polyoxyethylene ether successively after stirring Phosphate potassium salt 14%, 2-ethylaminoethanol 10%, Tween 1.5%, stir evenly to obtain the corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com