Preparation method of metal loaded catalyst with aluminum silicate as carrier

A supported catalyst, aluminum silicate technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve slow oxidation, low oxidation efficiency, ozone utilization Low selectivity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to express the production process and advantages of the present invention more clearly, the present invention will be further described below in conjunction with the examples.

[0017] 1. Weigh kaolin powder 20, aluminum hydroxide powder 75, metal ion active component 5, and pore-forming agent 0.1 by weight and mix fully with a mixer;

[0018] 2. Transport the mixed component materials into the sugar coating machine, spray the binder 35, and make the mixed powder into a shaped catalyst matrix with a particle size of 2~4mm;

[0019] 3. Then enter drying—heating and preheating—constant high temperature roasting—natural cooling

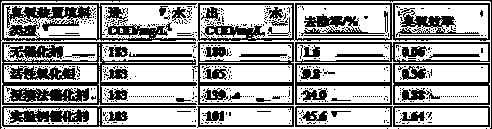

[0020] Catalyst carrier improvement ratio, the chemical composition ratio of each component is shown in the following table:

[0021]

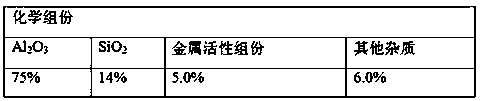

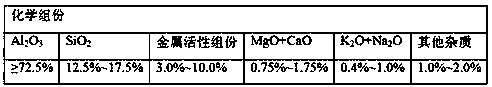

[0022] The carrier of the metal-loaded catalyst with aluminum silicate as the carrier, the main component is Al 2 o 3 and SiO 2 , the two substances are roasted at high temperature to produce alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com