Preparation method of molybdenum selenide-acetylene black composite material and application of molybdenum selenide-acetylene black composite material as catalyst in hydrogen evolution reaction

A composite material, a technology for hydrogen evolution reaction, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as hindering the wide application of hydrogen evolution reaction, large ion migration resistance, unreasonable pore size distribution, etc. Achieve the effect of improving electrochemical performance, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

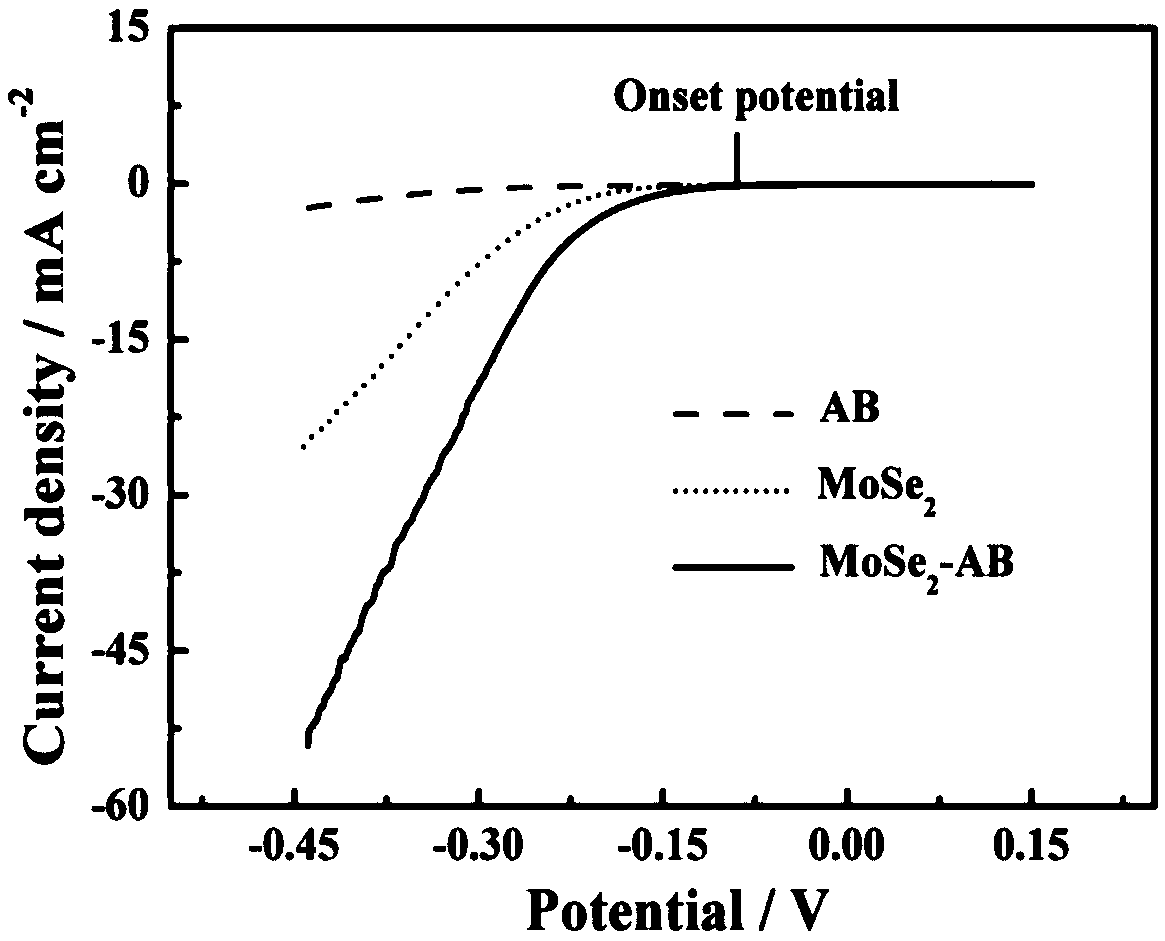

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of molybdenum selenide-acetylene black composite material of the present invention, detailed steps are as follows:

[0037] a, first weigh 0.15g selenium powder and 0.25g sodium molybdate Na 2 MoO 4 2H 2 0, the selenium powder and sodium molybdate taken by weighing are dissolved in 30mL secondary distilled water and are constantly stirred, when two kinds of materials dissolve fully, form a homogeneous solution, be recorded as solution ①;

[0038] b. At room temperature, add 5 mL of hydrazine hydrate dropwise to the solution ① obtained in step a and stir, and the solution obtained after stirring evenly is recorded as solution ②;

[0039] c. Acidification of acetylene black: Add 0.1g of acetylene black (commercially available acetylene black) into the mixed acid of concentrated sulfuric acid and concentrated nitric acid (when mixing, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 1:1), and heat to 85°C Under reflux...

Embodiment 2

[0047] The preparation method of molybdenum selenide-acetylene black composite material of the present invention, detailed steps are as follows:

[0048] a, first weigh 0.12g selenium powder and 0.20g sodium molybdate Na 2 MoO 4 2H 2 0, the selenium powder and sodium molybdate taken by weighing are dissolved in 25mL double-distilled water and are constantly stirred, when two kinds of materials are completely dissolved, a homogeneous solution is formed, which is recorded as solution ①;

[0049] b. At room temperature, add 4 mL of hydrazine hydrate dropwise to the solution ① obtained in step a and stir, and the solution obtained after stirring is recorded as solution ②;

[0050] c. Acidification of acetylene black: add 0.05g of acetylene black (commercially available acetylene black) into the mixed acid of concentrated sulfuric acid and concentrated nitric acid (when mixing, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 1:1), and heat to 80°C ...

Embodiment 3

[0058] The preparation method of molybdenum selenide-acetylene black composite material of the present invention, detailed steps are as follows:

[0059] a, first weigh 0.18g selenium powder and 0.30g sodium molybdate Na 2 MoO 4 2H 2 0, the selenium powder and sodium molybdate taken by weighing are dissolved in 40mL double-distilled water and are constantly stirred, when two kinds of materials are completely dissolved, a homogeneous solution is formed, which is recorded as solution ①;

[0060] b. At room temperature, add 6mL of hydrazine hydrate dropwise to the solution ① obtained in step a and stir, and the solution obtained after stirring evenly is recorded as solution ②;

[0061] c. Acidification of acetylene black: Add 0.15g of acetylene black (commercially available acetylene black) into the mixed acid of concentrated sulfuric acid and concentrated nitric acid (when mixing, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 1:1), and heat to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com