Aerogel vacuum insulated panel and preparation method thereof

A vacuum insulation panel and airgel technology, applied in chemical instruments and methods, other household appliances, lamination, etc., can solve the requirements of reduced heat insulation effect, low composite degree of airgel powder and insulation felt, and core sealing requirements Advanced problems, to achieve the effect of improving the effective service life, flexible and convenient construction methods, and little impact on product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

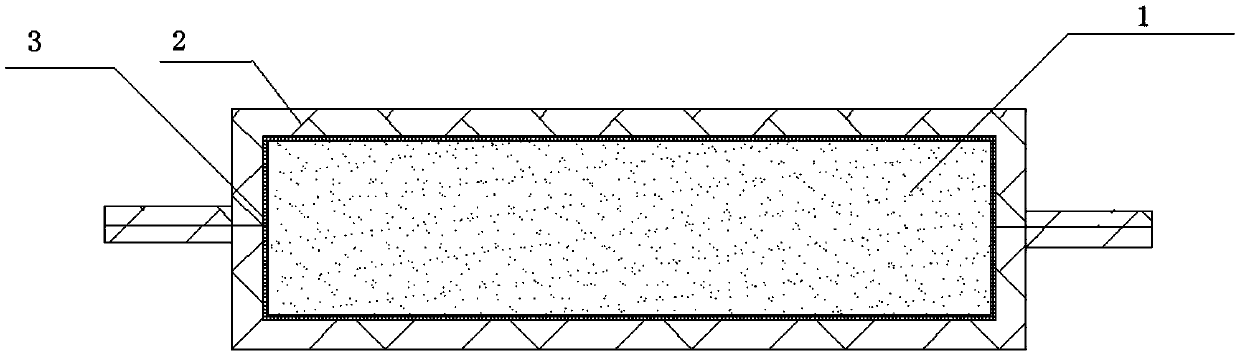

Image

Examples

preparation example Construction

[0026] In one embodiment, the preparation method of the airgel vacuum insulation panel comprises the following steps:

[0027] Fabrication of rigid airgel insulation panels

[0028] The airgel composite insulation board composited with airgel and reinforcing fiber is prepared by the sol-gel method, and the proportion of airgel in the composite insulation board can be controlled by controlling the concentration of the solution, so as to produce airgel with different strengths Composite insulation board, the airgel composite insulation board prepared by normal pressure drying method has strong hydrophobic performance. Concrete preparation steps are as follows:

[0029]Preparation of sol→introduction of sol into a mold with reinforcing fiber gel→integrated aging and acid alcoholization→surface modification→drying at normal pressure→airgel insulation board.

[0030] Reinforcing fibers are fibrous reinforcing materials, including: inorganic fibers and organic fibers. For example...

Embodiment 1

[0042] Weigh 60 g of sodium water glass with a modulus of 2.8, add 100 g of pure water and stir evenly. Use 40wt% sulfuric acid to adjust the pH until it reaches 5. Pour the sol into a mold with a 10cm thick pre-oxygenated fiber felt. The sol will gel after 10min, and then stand at 50°C for 1h. Then the integrated aging hydrogel plate was treated at 50°C for 5 hours. Put the alcoholized gel plate into 1200ml of trimethyldisilane and treat it at 60°C. Hydrophobic modification and gel drainage will be completed in one step within 5 hours. After the liquid drainage is completed, heat-dry the wet gel plate at a temperature of 80°C, and the drying is completed within 30 minutes to obtain an airgel insulation board. Cover the airgel insulation board with a laminated bag, and evacuate it with a vacuum pump. The vacuum pressure is 0.2 Pa, and the airgel vacuum insulation panel is obtained by hot pressing and sealing. The airgel vacuum insulation panel has a smooth surface and a therm...

Embodiment 2

[0044] Weigh 60 g of sodium water glass with a modulus of 3.6, add 100 g of pure water and stir evenly. Use 40wt% sulfuric acid to adjust the pH until it reaches 4. Pour the sol into a mold with a 20cm thick glass fiber needle felt. The sol will gel after 30min, and then stand at 50°C for 1h. Then the integrated aging hydrogel plate was treated at 50°C for 5 hours. Put the alcoholized gel plate into 1200ml of trimethyldisilane and treat it at 60°C. Hydrophobic modification and gel drainage will be completed in one step within 5 hours. After the liquid drainage is completed, heat-dry the wet gel plate at a temperature of 80°C, and the drying is completed within 30 minutes to obtain an airgel insulation board. Cover the airgel insulation board with a laminated bag, and evacuate it with a vacuum pump. The vacuum pressure is 0.01Pa, and the airgel vacuum insulation panel is obtained by hot pressing and sealing. The airgel vacuum insulation panel has a smooth surface and a thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com