A kind of processing method of broken leather

A processing method and peeling technology, applied in chemical instruments and methods, lamination, application, etc., can solve the problems of low added value of products, low utilization rate of leather materials, coarse fiber structure, etc., and achieve excellent gloss and damage repair. Good effect and soft feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] A kind of processing method of broken leather of the present embodiment, comprises the following steps:

[0096] (1) Material selection: choose one or two of the broken leather and leftover leather materials as the leather embryo, and set aside;

[0097] (2) Coating filling resin: coating a layer of filling resin material on the leather embryo;

[0098] (3) Roller balding and compaction: use a roller glazing machine to perform multiple roller coating processes on the leather embryo coated with resin-filled materials, so that the leather embryo can reach the real feeling of the first layer of skin;

[0099] (4) Scratching and repairing ointment: apply a layer of repairing ointment on the leather embryo with a scraper;

[0100] (5) Calendering: use a roller calender to flatten the skin embryo;

[0101] (6) The first roll coating of masking resin: apply a layer of masking resin on the leather embryo to cover the defective parts of the leather embryo;

[0102] (7) Sand p...

Embodiment 2

[0145] The difference between this embodiment and embodiment 1 is: the filling resin of this embodiment is made up of the raw material of following weight part:

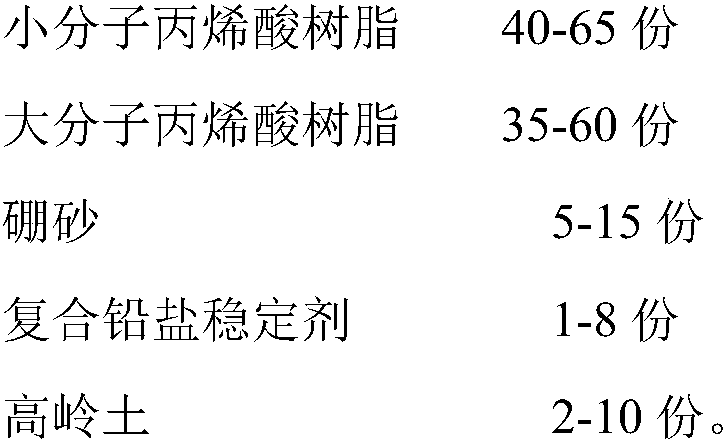

[0146] Small molecule acrylic resin 40-65 parts

[0147] Macromolecular acrylic resin 35-60 parts

[0148] Borax 5-15 parts

[0149] Composite lead salt stabilizer 1-8 parts

[0150] Kaolin 2-10 parts.

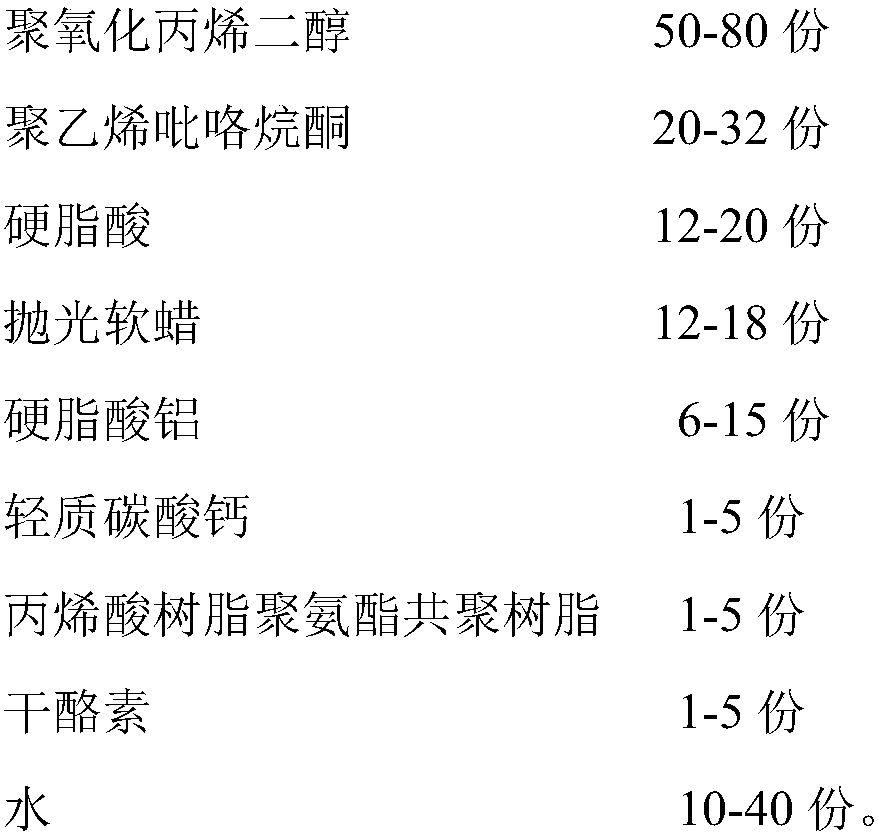

[0151] Wherein, the repairing ointment consists of the following raw materials in parts by weight:

[0152] Polyoxypropylene glycol 50-80 parts

[0153] 20-32 parts of polyvinylpyrrolidone

[0154] Stearic acid 12-20 parts

[0155] Polishing soft wax 12-18 parts

[0156] Aluminum stearate 6-15 parts

[0157] Light calcium carbonate 1-5 parts

[0158] Acrylic resin polyurethane copolymer resin 1-5 parts

[0159] Casein 1-5 parts

[0160] 10-40 parts of water.

[0161] Wherein, the masking resin consists of the following raw materials in parts by weight:

[0162] 20-35 parts of polybutadiene resin

[0163...

Embodiment 3

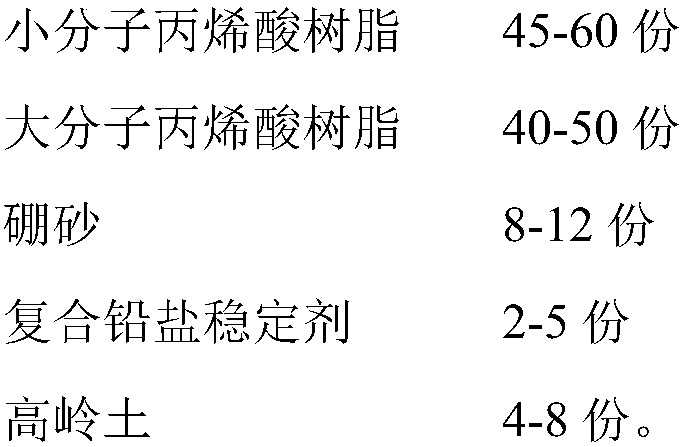

[0185] The difference between this embodiment and embodiment 1 is: the filling resin of this embodiment is made up of the raw material of following weight part:

[0186] Small molecule acrylic resin 40-65 parts

[0187] Macromolecular acrylic resin 35-60 parts

[0188] Borax 5-15 parts

[0189] Composite lead salt stabilizer 1-8 parts

[0190] Kaolin 2-10 parts.

[0191] Wherein, the repairing ointment consists of the following raw materials in parts by weight:

[0192] Polyoxypropylene glycol 50-80 parts

[0193] 20-32 parts of polyvinylpyrrolidone

[0194] Stearic acid 12-20 parts

[0195] Polishing soft wax 12-18 parts

[0196] Aluminum stearate 6-15 parts

[0197] Light calcium carbonate 1-5 parts

[0198] Acrylic resin polyurethane copolymer resin 1-5 parts

[0199] Casein 1-5 parts

[0200] 10-40 parts of water.

[0201] Wherein, the masking resin consists of the following raw materials in parts by weight:

[0202] 20-35 parts of polybutadiene resin

[0203...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com