A kind of immobilization method of anaerobic bacteria

A technology of anaerobic bacteria and calcium chloride, applied in chemical instruments and methods, fixed on/in organic carriers, water/sludge/sewage treatment, etc., can solve problems such as easy adhesion, and achieve a solution to adhesion , Realize the effect of large-scale equipment production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

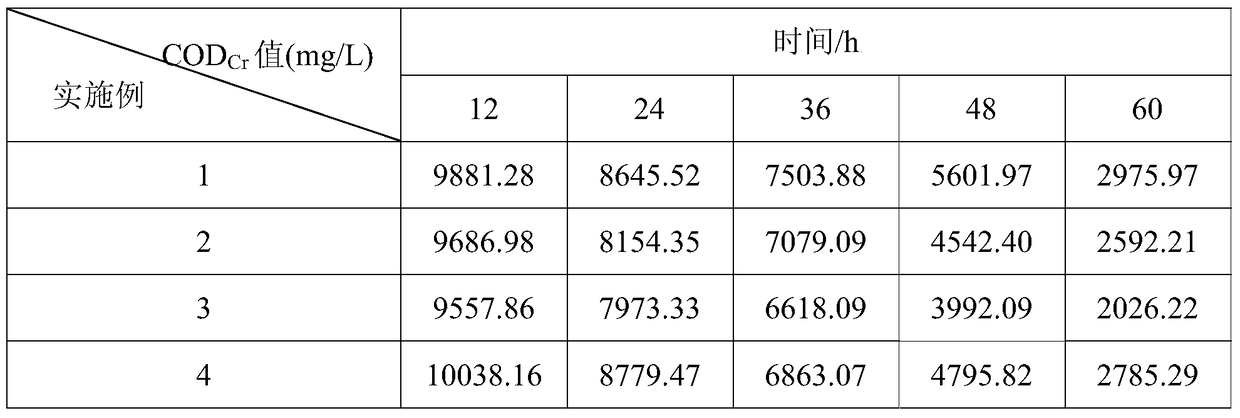

Examples

Embodiment 1

[0048] (1) Prepare curing agent: add boric acid to 500mL distilled water and dissolve to obtain saturated boric acid solution, weigh 6gCaCl 2 , 0.6g talcum powder, join in the saturated boric acid solution, make curing agent.

[0049] (2) Preparation of growth factor solution: 10.0 mg each of vitamin B1, vitamin B6, and nicotinic acid, 3 g of glucose, and 0.15 g of ammonium tartrate were added to 500 mL of water to prepare a growth factor solution.

[0050] (3) Preparation of immobilized anaerobic bacteria particles: Add 6 g of polyvinyl alcohol, 2 g of sodium alginate and 10 g of zeolite powder with a particle size of 200 mesh to 200 mL of growth factor solution, heat to 50 ° C, and continuously stir at a speed of 70 rpm for 1 hour. A mixed slurry is prepared. After the temperature of the mixed slurry was lowered to 30° C., 10 mL of anaerobic bacteria was added to the mixed slurry, and the stirring was continued to prepare a mixed slurry containing anaerobic bacteria. Use a...

Embodiment 2

[0052] (1) Prepare curing agent: add boric acid to 500mL distilled water and dissolve to obtain saturated boric acid solution, weigh 55gCaCl 2 , 5g talcum powder, join in the saturated boric acid solution, make curing agent.

[0053] (2) Preparation of growth factor solution: 15.0 mg each of vitamin B1, vitamin B6, and nicotinic acid, 4 g of glucose, 0.15 g of ammonium tartrate, and 5 mL of 25% ethanol solution were added to 500 mL of distilled water to prepare a growth factor solution.

[0054] (3) Preparation of immobilized anaerobic bacteria granules: Add 20 g of polyvinyl alcohol, 0.2 g of sodium alginate and 3.3 g of activated carbon powder with a particle size of 325 mesh to 200 mL of growth factor solution, heat to 120 ° C, and continuously stir at 80 rpm for 50 min , to prepare a mixed slurry. After the temperature of the mixed slurry was lowered to 45° C., 10 mL of anaerobic bacteria was added to the mixed slurry, and the stirring was continued to prepare a mixed slu...

Embodiment 3

[0056] (1) Prepare curing agent: add boric acid to 500mL distilled water and dissolve to obtain a saturated boric acid solution, weigh 20g CaCl 2 , 2g talcum powder, join in the saturated boric acid solution, make curing agent.

[0057] (2) Preparation of growth factor solution: 20.0 mg each of vitamin B1, vitamin B6, and nicotinic acid, 3 g of glucose, and 3 mL of 25% ethanol solution were added to 500 mL of tap water to prepare a growth factor solution.

[0058] (3) Preparation of immobilized anaerobic bacteria granules: 10 g of sodium alginate was added to 200 mL of growth factor solution, heated to 70° C., and continuously stirred at 60 rpm for 100 min to prepare a mixed slurry. After the temperature of the mixed slurry was lowered to 35° C., 10 mL of anaerobic bacteria was added to the mixed slurry, and the stirring was continued to prepare a mixed slurry containing anaerobic bacteria. Use a 50mL syringe with a needle to draw the mixed slurry containing anaerobic bacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com