A kind of Poria cocos cellulose fiber and preparation method thereof

A cellulose fiber and cellulose technology, applied in the field of Poria cocos cellulose fiber and its preparation, can solve the problems of high rate of ultra-long fibers, rapid loss of effective substances, large coefficient of variation of dry breaking strength, etc., and achieve improvement of hyperglycemia, Good antibacterial effect and good avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

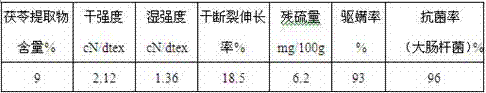

Embodiment 1

[0037] Embodiment 1 Specification is the preparation method of the Poria cocos cellulose fiber of 1.11dtex*32mm

[0038] The preparation of step 1, Poria cocos microcapsules

[0039] (1) Selection of raw materials

[0040] Poria cocos extract is selected as the raw material of Poria cocos microcapsules. The poria cocos extract is a brown yellow powder, 100% of which passes through an 80 mesh sieve, the content of polysaccharides is 60%, the ash content is ≤3.2%, the water content is ≤3.8%, and the heavy metal content≤5ppm, lead content≤1ppm, arsenic content≤0.5ppm, mercury content≤0.4ppm, total number of bacteria≤500cfu / g, total number of mold≤50cfu / g, Salmonella and Escherichia coli should not be detected.

[0041] (2) Preparation of organic phase

[0042] Select carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic acid to make composition A and dissolve in isobutyl acetate solution, the carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic ...

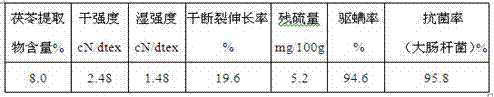

Embodiment 2

[0067] Embodiment 2 specification is the preparation method of the Poria cocos cellulose fiber of 1.33dtex*38mm

[0068] The preparation of step 1, Poria cocos microcapsules

[0069] (1) Selection of raw materials

[0070] Poria cocos extract is selected as the raw material of Poria cocos microcapsules. The poria cocos extract is a brownish yellow powder, 100% of which passes through an 80 mesh sieve, and the content of poria cocos polysaccharide is 65%, the ash content≤3.5%, the moisture content≤3.3%, heavy metal content≤5ppm, lead content≤1ppm, arsenic content≤0.5ppm, mercury content≤0.4ppm, total number of bacteria≤500cfu / g, total number of mold≤50cfu / g, Salmonella and Escherichia coli should not be detected.

[0071] (2) Preparation of organic phase

[0072] Select carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic acid to make composition A and dissolve in isobutyl acetate solution, the carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacr...

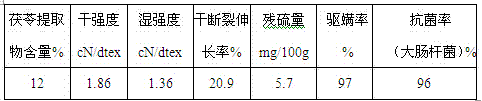

Embodiment 3

[0097] Embodiment 3 specification is the preparation method of the Poria cocos cellulose fiber of 1.67dtex*38mm

[0098] The preparation of step 1, Poria cocos microcapsules

[0099] (1) Selection of raw materials

[0100] Poria cocos extract is selected as the raw material of Poria cocos microcapsules. The poria cocos extract is a brown yellow powder, 100% of which passes through an 80 mesh sieve, the content of polysaccharides is 70%, the ash content is ≤2.8%, the water content is ≤3.2%, and the heavy metal content≤5ppm, lead content≤1ppm, arsenic content≤0.5ppm, mercury content≤0.4ppm, total number of bacteria≤500cfu / g, total number of mold≤50cfu / g, Salmonella and Escherichia coli should not be detected.

[0101] (2) Preparation of organic phase

[0102]Select carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic acid to make composition A and dissolve in isobutyl acetate solution, the carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com