High-temperature gas-cooled reactor helium and indirect cyclic hydrogen production coupled power generation system and method

A high-temperature gas-cooled reactor and hydrogen production system technology, which is applied in the direction of machines/engines, gas turbine devices, and combined combustion mitigation, can solve the problem of inability to meet the requirements of helium turbine intake parameters and the complete coupling of nuclear power plants and hydrogen production processes. and other problems, to achieve good application prospects, improve energy utilization, and reduce the effect of cold source loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Device

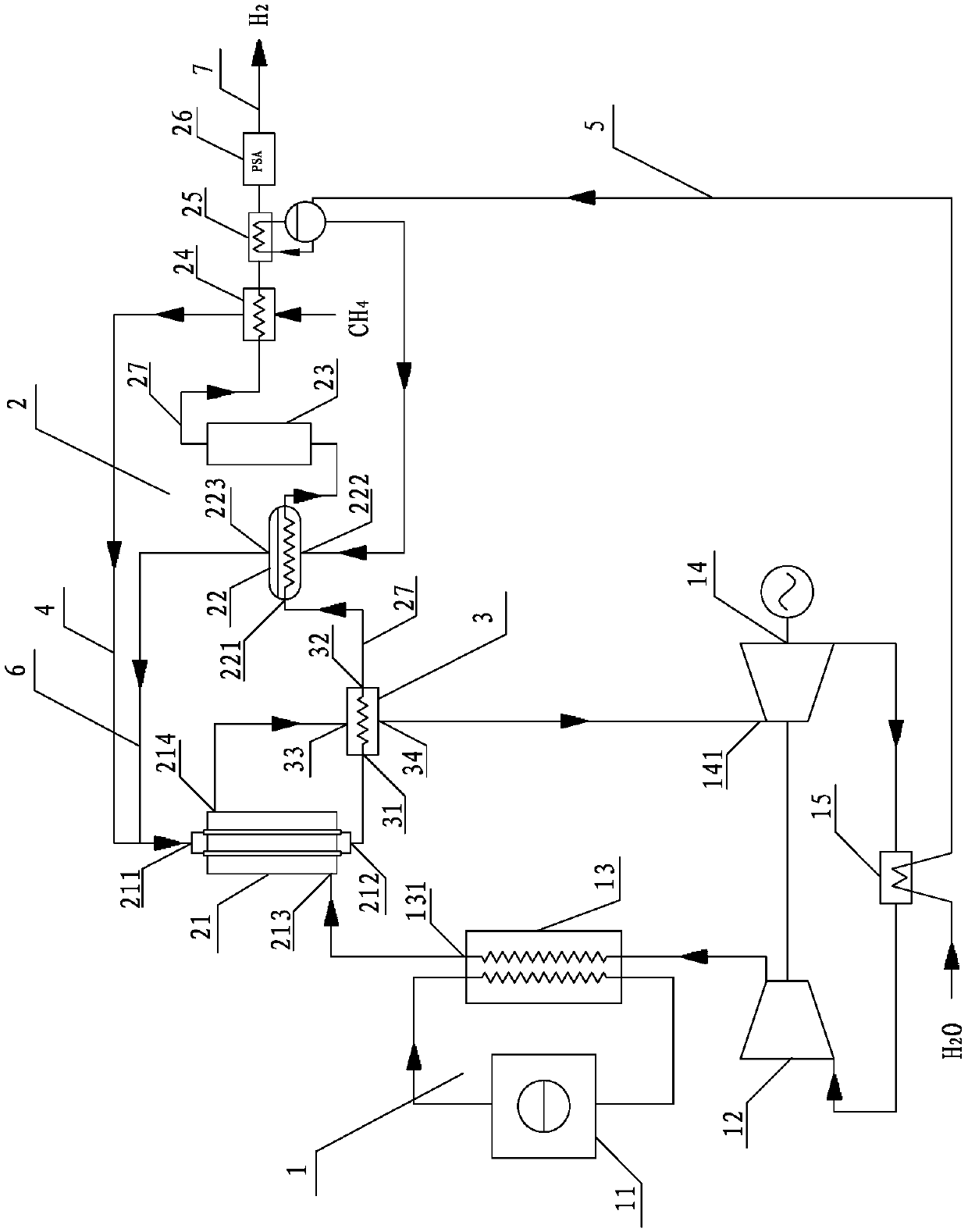

[0020] The present invention is a high-temperature gas-cooled reactor helium indirect circulation coupled power generation system for hydrogen production, which includes a nuclear power generation system 1, a hydrogen production system 2, a high-pressure helium reheater 3, a methane delivery pipeline 4, a water supply pipeline 5, water vapor Pipeline 6, hydrogen delivery pipeline 7.

[0021]The nuclear power generation system 1 is composed of a high-temperature gas-cooled reactor 11, a compressor 12, a helium-helium heat exchanger 13, a helium gas turbine 14, and a cooler 15; the high-temperature gas-cooled reactor 11 and the helium-helium heat exchanger 13 The primary side of the nuclear power plant is connected to form the primary circuit of the nuclear power plant; the compressor 12 is connected with the secondary side of the helium-helium heat exchanger 13, the helium turbine 14, and the cooler 15 to form the secondary circuit part of the nuclear power p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com