Cryogenic separation recycling system and method for exhausted polyolefin flare gas

A cryogenic separation and recovery system technology, which is applied in refrigeration, liquefaction, liquefaction, solidification, etc., can solve problems such as the decline in the recovery rate of hydrocarbons, the damage of the rotor of the turbo expander, and the low pressure of the tail gas at the expansion outlet, and achieve the ultimate goal. The effect of optimizing the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

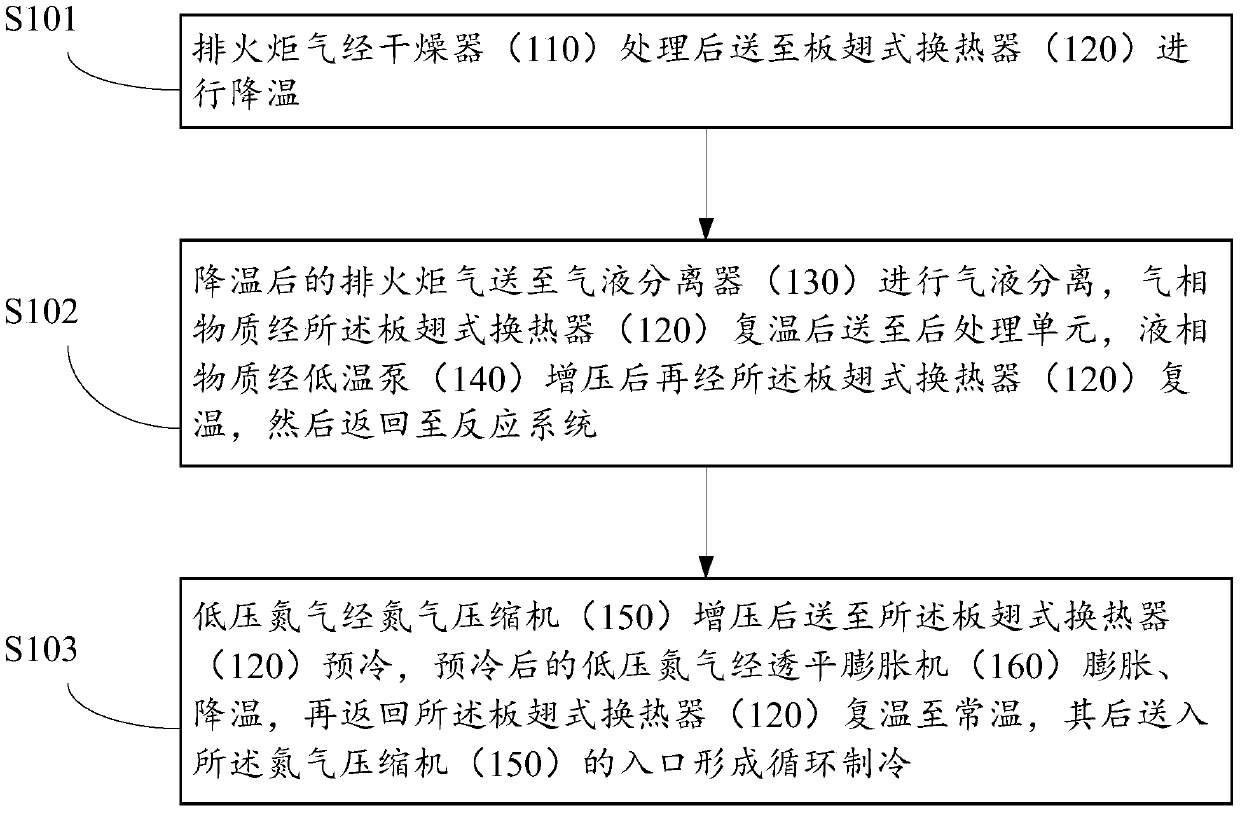

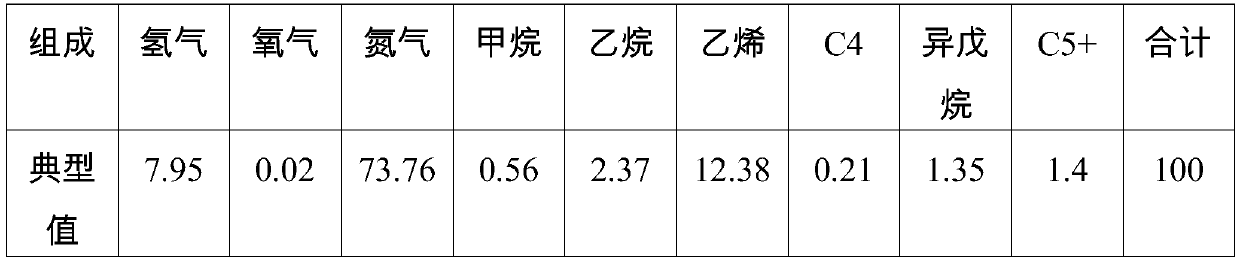

[0038] The exhaust gas of a full-density polyethylene production unit in a petrochemical company is recovered by compression and condensation, and the tail gas is discharged to the flare. The pressure range is 1.1~1.6 (typically 1.3) MPa(G), the temperature range is -15~0 (typically -10)°C, and the flow rate is 900~1200 (typically 1045) Nm3 / h.

[0039] Table 1 The measured value of the composition of the flare gas (v%)

[0040]

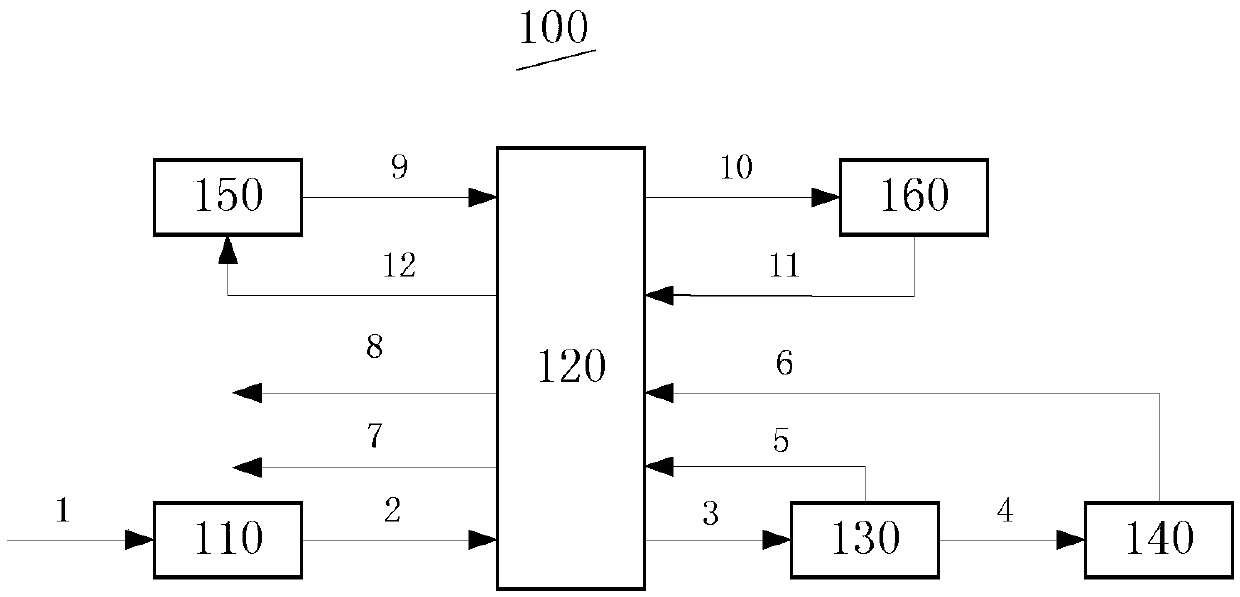

[0041] The exhaust torch gas (stream 1) first enters the dryer 110 for treatment, and when the dew point reaches about -70°C, it is sent to the plate-fin heat exchanger 120, and the temperature drops to -120°C step by step, and then sent to the gas-liquid separator 130, The separated gaseous substances are reheated by the plate-fin heat exchanger 120 and sent out of the boundary area (stream 7); the separated liquid-phase substances are pressurized to 3.2 MPa (G) by the cryopump, and then rewarmed by the plate-fin heat exchanger Then sent to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com