System and method for treating low-rank coal

A low-rank coal and clean coal technology, applied in the field of coal chemical industry, can solve problems such as polluting the environment, affecting the quality of processed products, and increasing the moisture content of coal preparation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

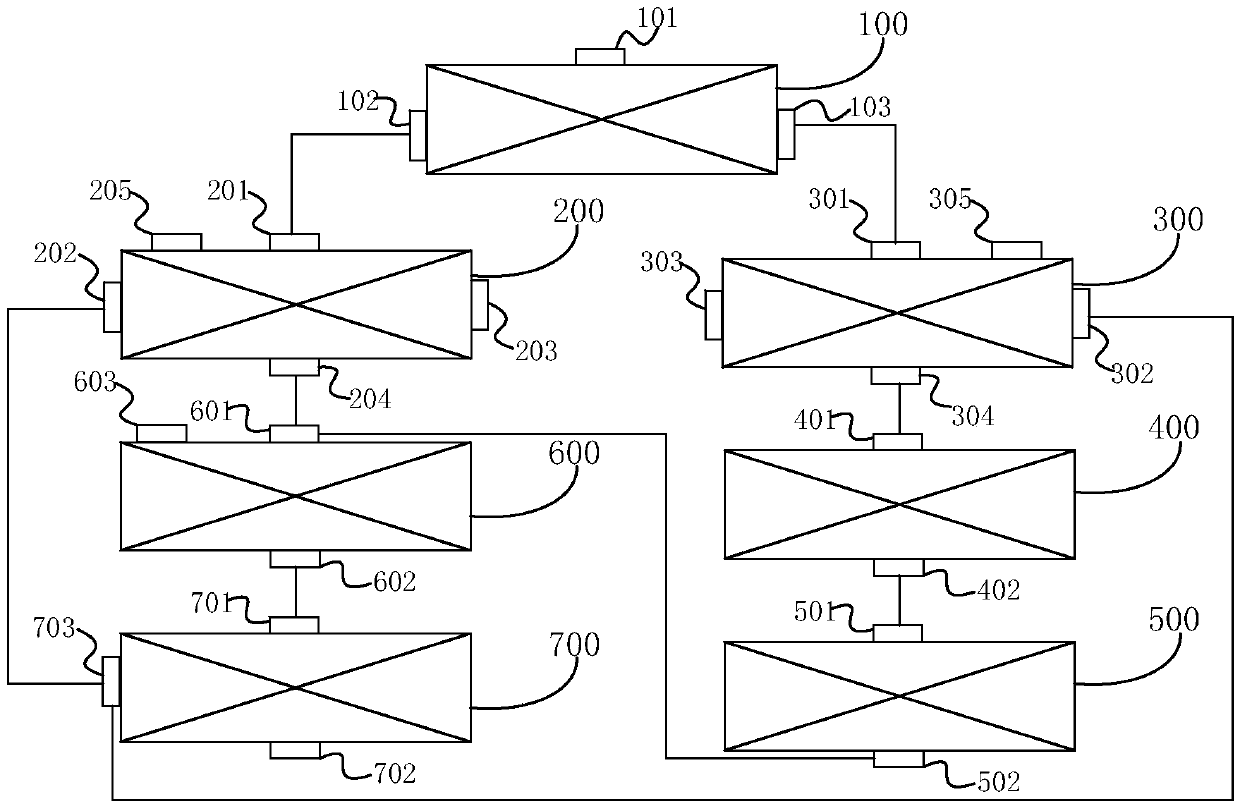

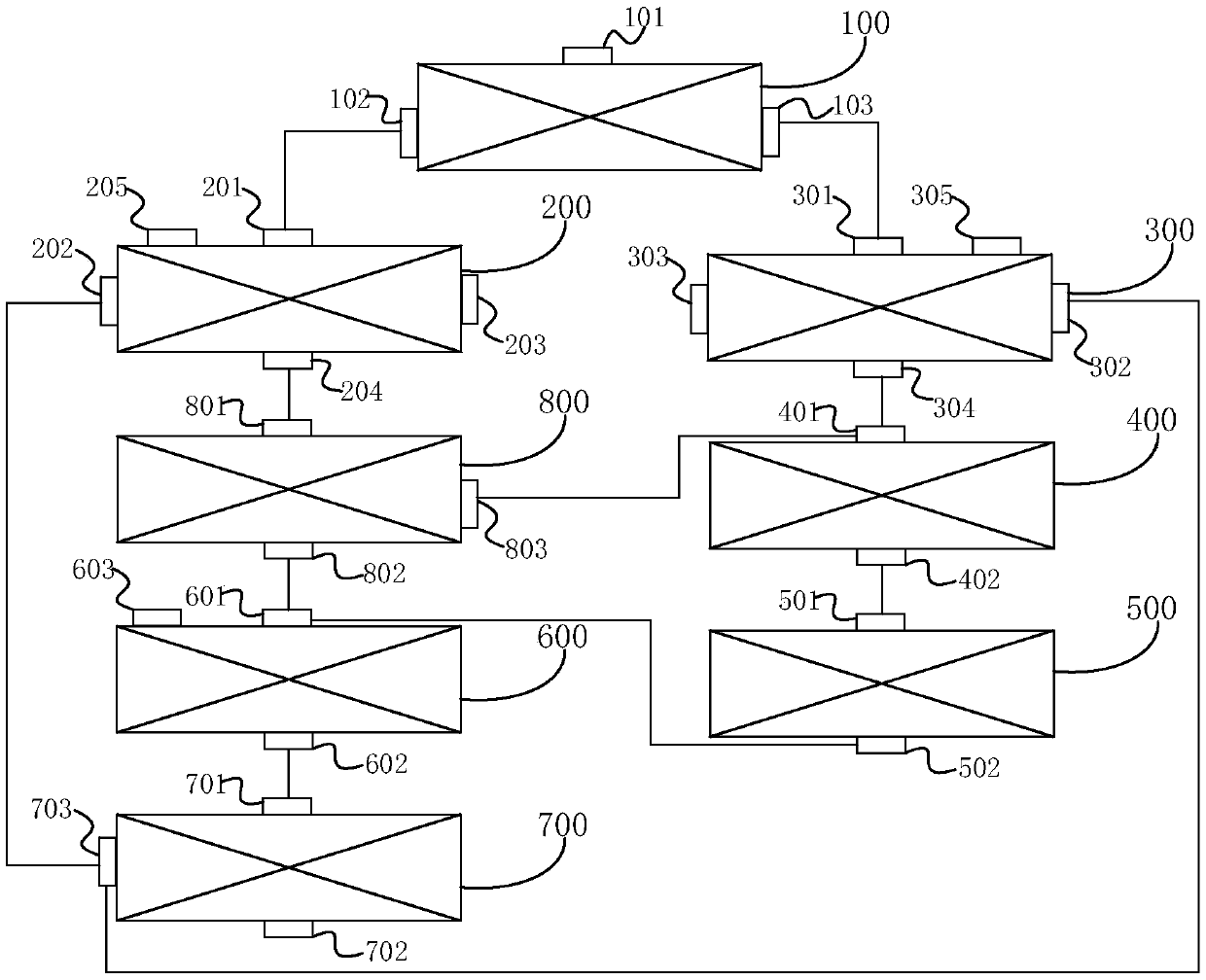

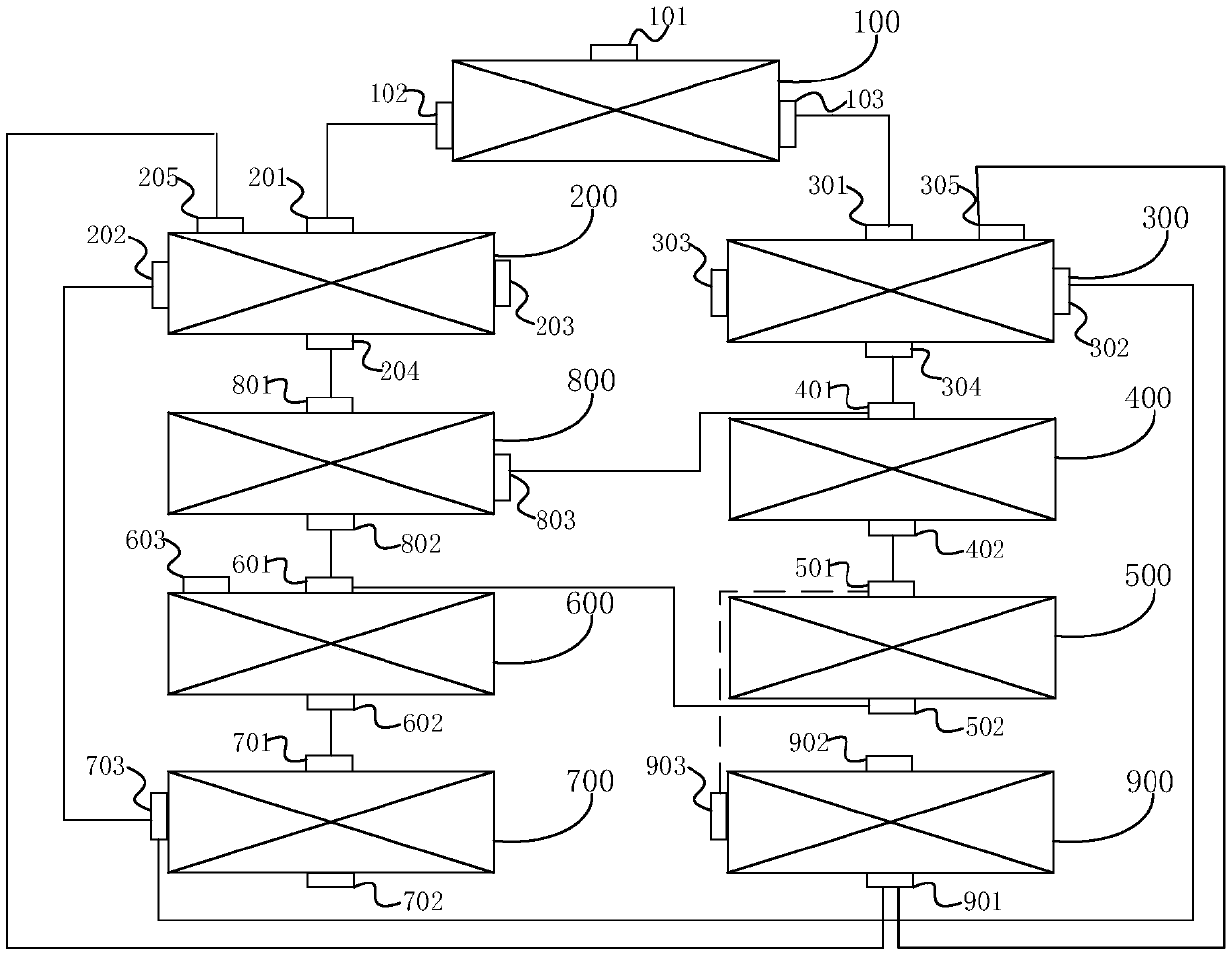

[0075] In yet another aspect of the present invention, the present invention provides a method for processing low-rank coal. According to an embodiment of the present invention, the method is carried out by using the above-mentioned system for processing low-rank coal. According to a specific embodiment of the present invention, the method includes: (1) supplying the low-rank coal to the low-rank coal screening device for screening, so as to obtain the above-screen low-rank coal and the under-screen low-rank coal (2) supplying the low-rank coal on the sieve to the lump coal hot-air composite sorting device and adopting the first hot air to discharge and dry the low-rank coal on the sieve, so as to obtain the first gangue respectively , the first clean coal and the first tail gas containing dust; (3) supply the under-screen low-rank coal to the pulverized coal hot air flow separation device and use the second hot air to discharge the under-screen low-rank coal Gangue and dry t...

Embodiment

[0109] use Figure 7 The system for processing lignite shown in this example processes lignite raw coal. The raw coal processing capacity of this embodiment is 1 million tons per year, the processing particle size range is full particle size, and the raw coal receives a base moisture of 33.5wt%. The specific implementation method includes the following sequence Process steps:

[0110] 1) The lignite raw coal is first supplied to the low-rank coal screening device (the sieve aperture is 6mm) from the raw coal bunker to obtain the above-sieve lignite (particle size not less than 6mm) and the under-sieve lignite (particle size less than 6mm);

[0111] 2) The lignite on the sieve is fed into the lump coal hot-air compound sorting device through the belt, and the hot air enters the lump coal hot-air compound sorting device from the bottom. After being sorted in the coal-hot-air compound sorting device, the first gangue is discharged from the gangue discharge port at the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com