Lithium ion battery and preparation method thereof

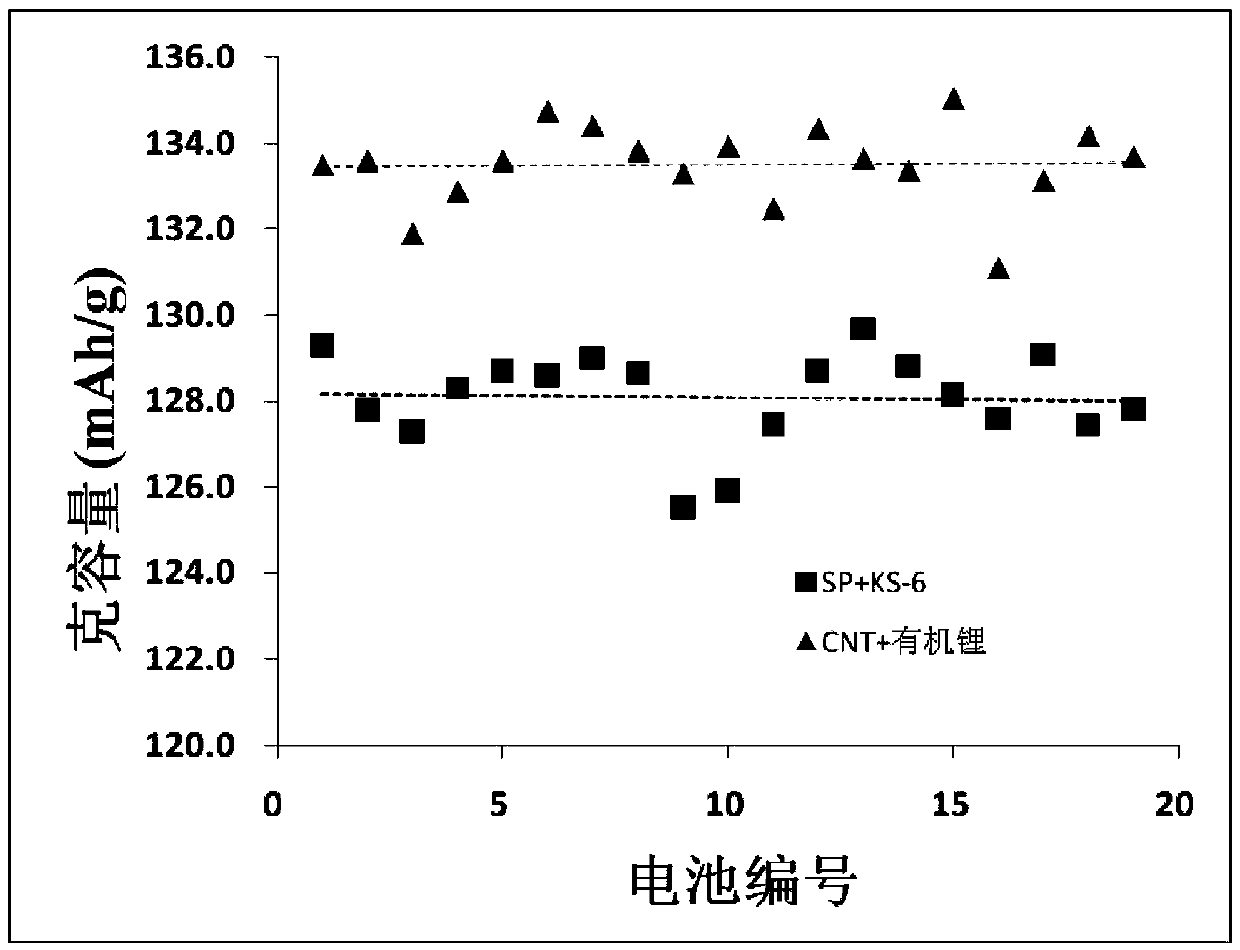

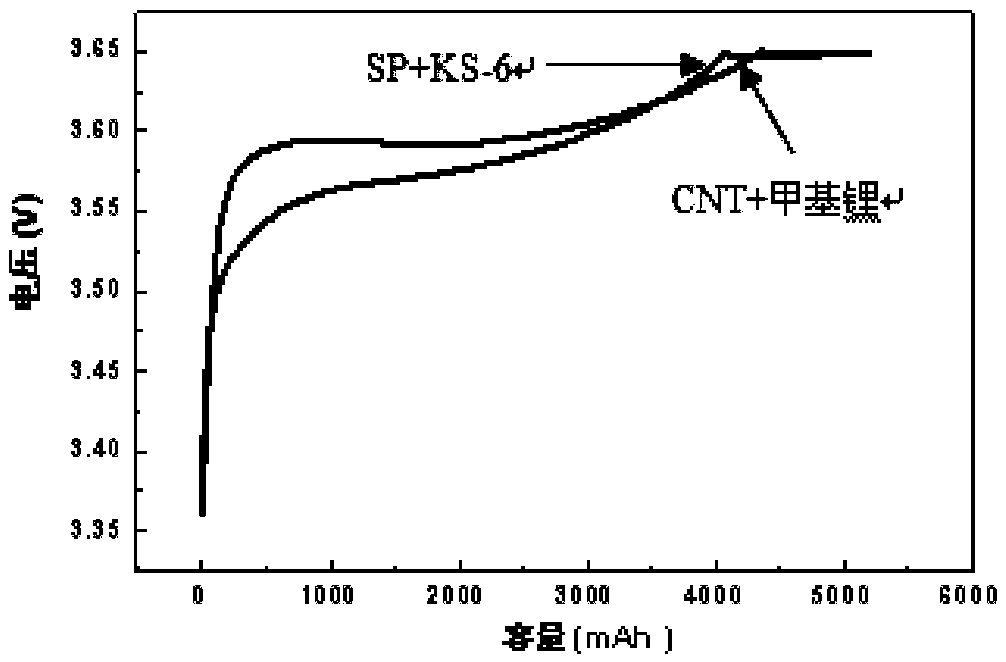

A technology for lithium-ion batteries and battery casings, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve problems affecting cycle life, poor conductivity, hindering mass transfer, etc. Improve cycle performance and increase the effect of gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Prepare a lithium battery according to the technical scheme of the present invention, the steps are as follows:

[0039] (1) Take each component according to 95% lithium iron phosphate, 2% carbon nanotubes, 0.5% methyllithium, and 2.5% PVDF, and weigh NMP solvent according to the amount at the same time, and the weighed NMP is the mass of four solid substances 45% of;

[0040] (2) Take out PVDF and part of NMP, be mixed with the glue solution that mass fraction is 10%, stand-by after dispersing;

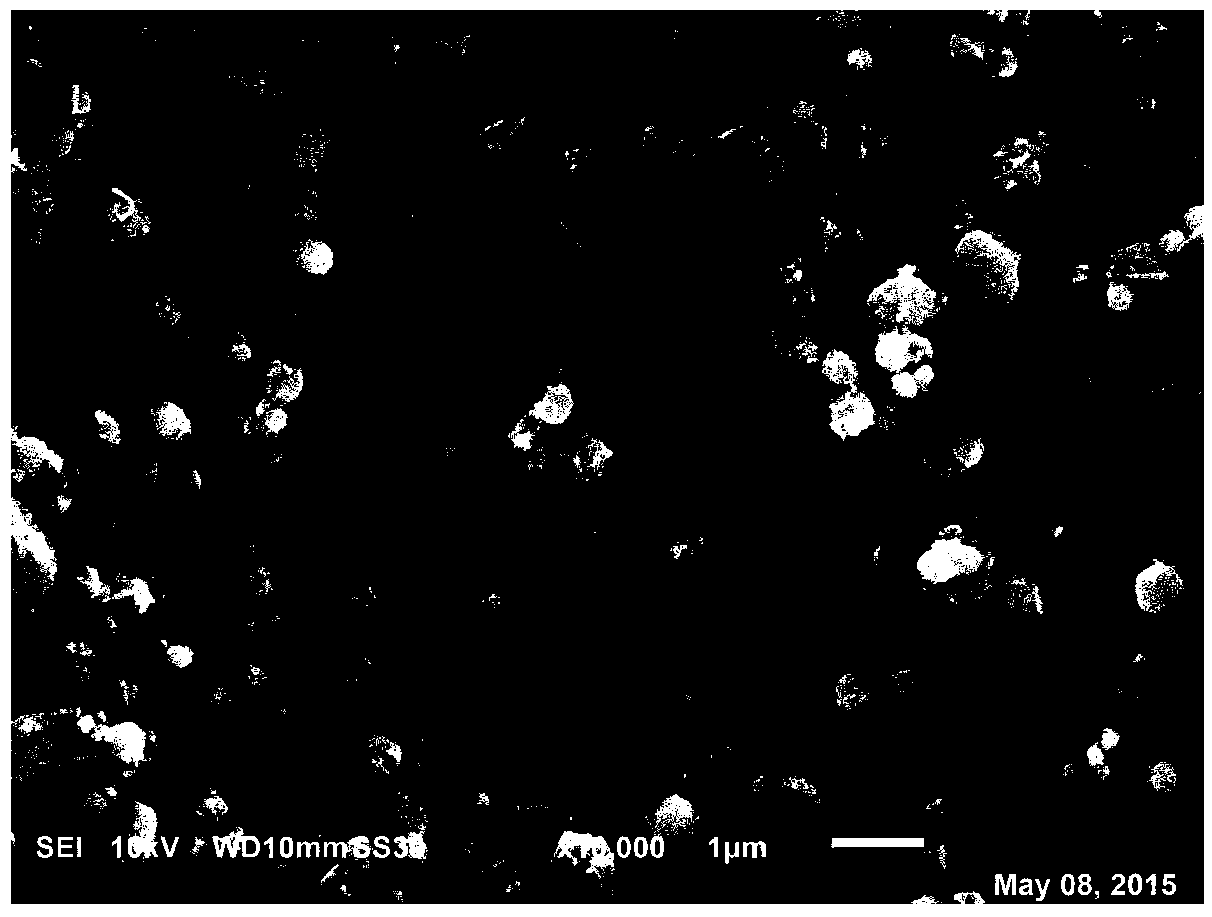

[0041] (3) Add carbon nanotubes and methyllithium to the remaining NMP, and disperse at a high speed for 1 hour at a rotation frequency of 45 Hz and a revolution of 40 Hz under vacuum conditions, and then undergo ultrasonic dispersion for 30 minutes. The ultrasonic dispersion process conditions are 15-20KHz, and the power 200-300W, then add lithium iron phosphate for the second high-speed dispersion for 4 hours;

[0042] (4) Add the glue into the dispersed slurry and mix and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com