SCR (selective catalytic reduction) denitration device for low-dust flue gas in thermal power plant and denitration method

A technology for thermal power plants and SCR reactors, applied in the field of exhaust gas purification, can solve the problems of high dust concentration in flue gas, wear and tear of SCR flue and equipment, and inability to use it, so as to improve operating economy, reduce project investment, and save transformation. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

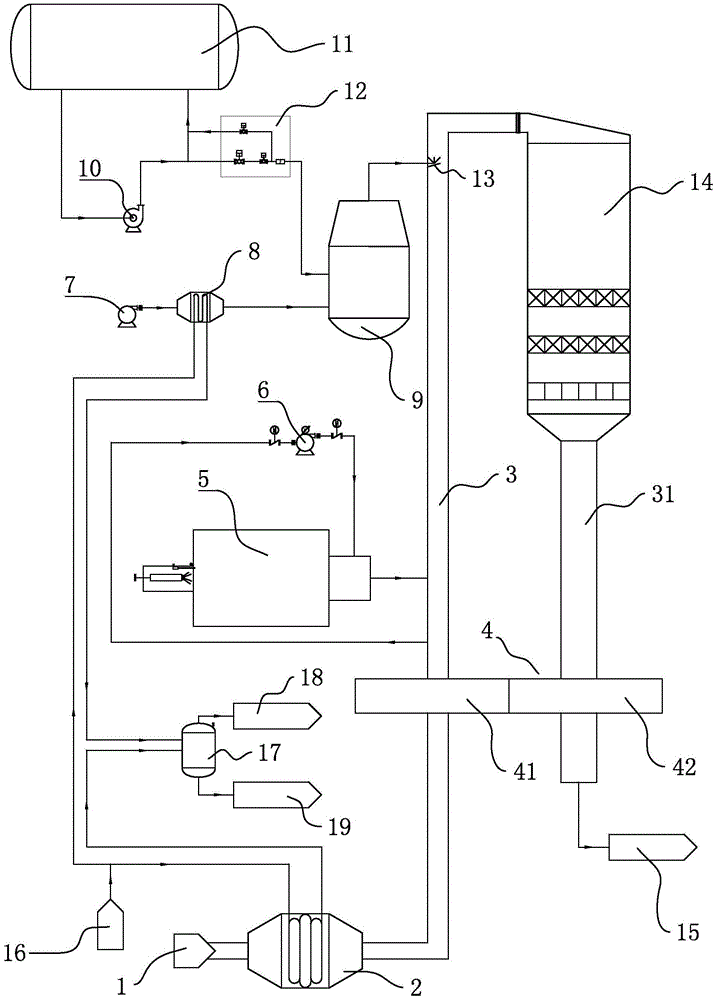

[0035] like figure 1 As shown, the flue includes the original flue gas flue 3 and the clean flue gas flue 31. The inlet end of the original flue gas flue 3 is provided with a flue gas steam heater 2, and the flue gas 1 after the dust collector of the unit passes through the inlet end. Into the flue gas steam heater 2. The outlet end of the original flue gas flue 3 is provided with an SCR reactor 14, the SCR reactor 14 communicates with the clean flue gas flue 31, and the flue gas treated by the SCR reactor 14 is discharged through the clean flue gas flue 31, where it can be It is connected with the discharge interface 15 set by the user according to actual needs. The denitrification device of the present application also includes a flue gas heat exchanger 4 which is internally divided into an original flue gas chamber 41 and a clean flue gas chamber 42. The flue gas flue 31 is connected. The original flue gas flue 3 communicates with the hot blast stove 5 . For the conveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com