Catalytic cracking catalyst regeneration method and device

A regeneration equipment and catalytic cracking technology, which is applied in catalyst regeneration/reactivation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor fluidization effect, high price of platinum, To solve problems such as limited resources, achieve the effect of improving product distribution, reducing carbon content, and improving regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

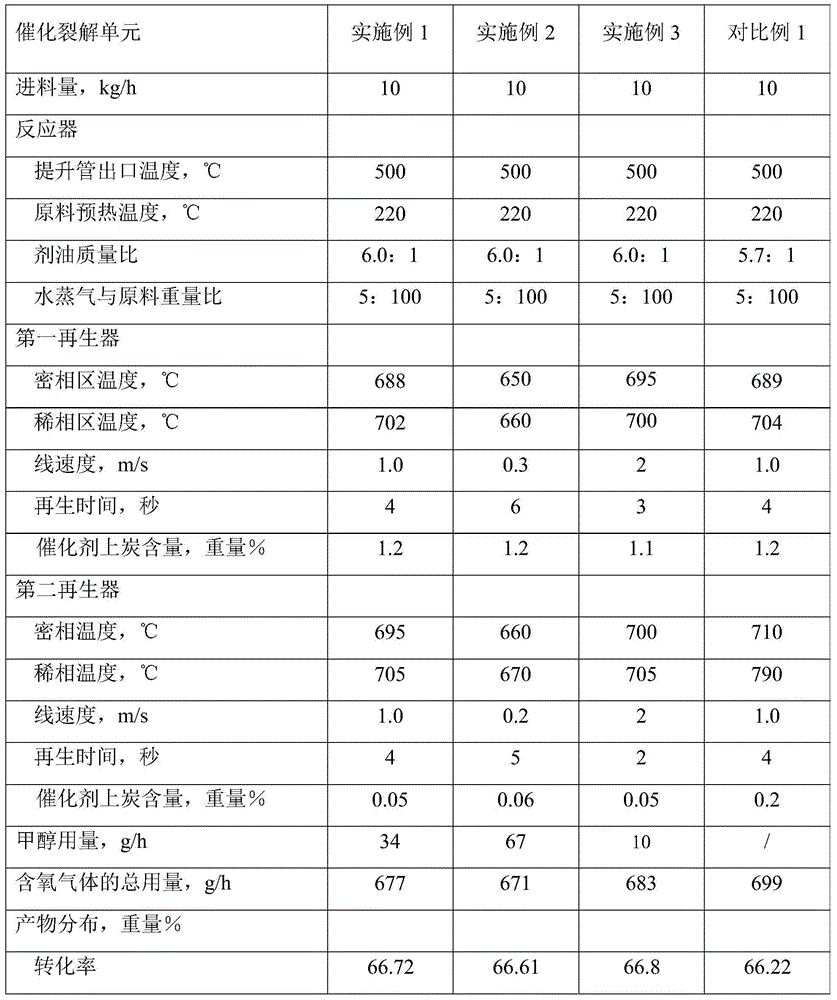

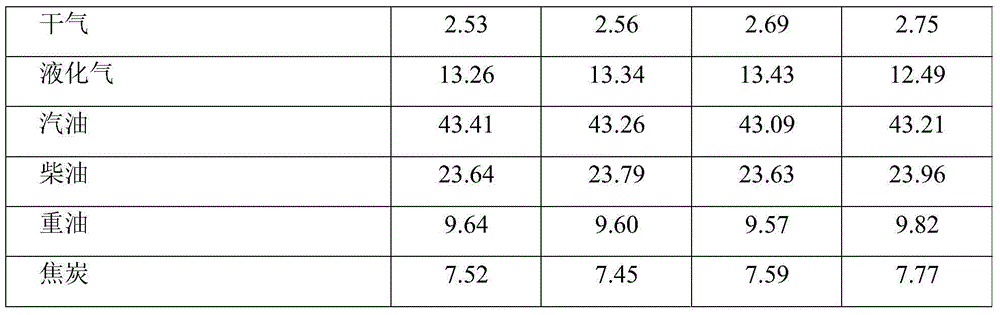

[0054] This example is used to illustrate the effect of the catalytic cracking catalyst regeneration method and equipment provided by the present invention.

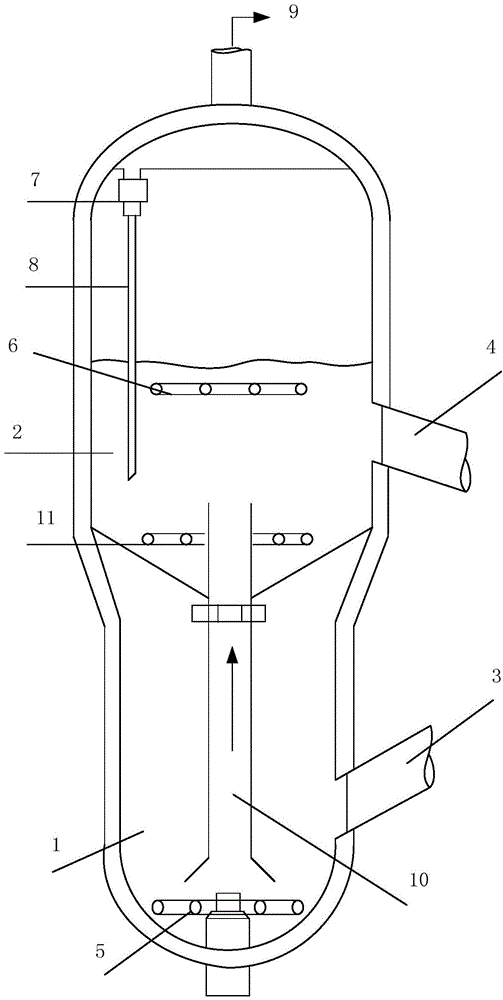

[0055] Using vacuum residue as raw material, the catalytic cracking catalyst is MLC-500, and the test is carried out on a medium-sized riser reactor. The structure of the regenerator is as figure 1 As shown, the spent catalyst from the inclined tube 3 of the spent catalyst enters the catalyst dense-phase area of the first regenerator 1, and performs incomplete regeneration with the oxygen-containing gas from the first main air distributor 5, and the semi-regenerated catalyst passes through the conduit 10 Enter the middle and lower part of the catalyst dense phase area of the second regenerator 2, contact with the oxygen-containing gas from the second main air distributor 11 for complete regeneration, the generated gas containing CO moves upward, and the methanol enters the second regenerator through the methanol dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com