Filler and preparation method thereof

A technology of polyurethane foam and activated carbon, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as insufficient microbial load, small specific surface area of filler, complex production process, etc., to achieve The effect of promoting stable reproduction and growth, small volume density, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

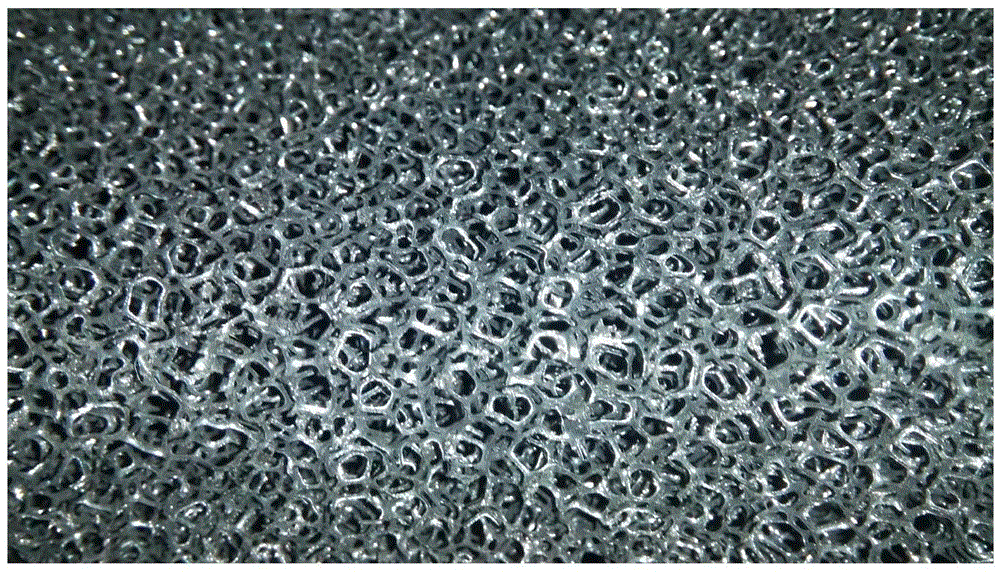

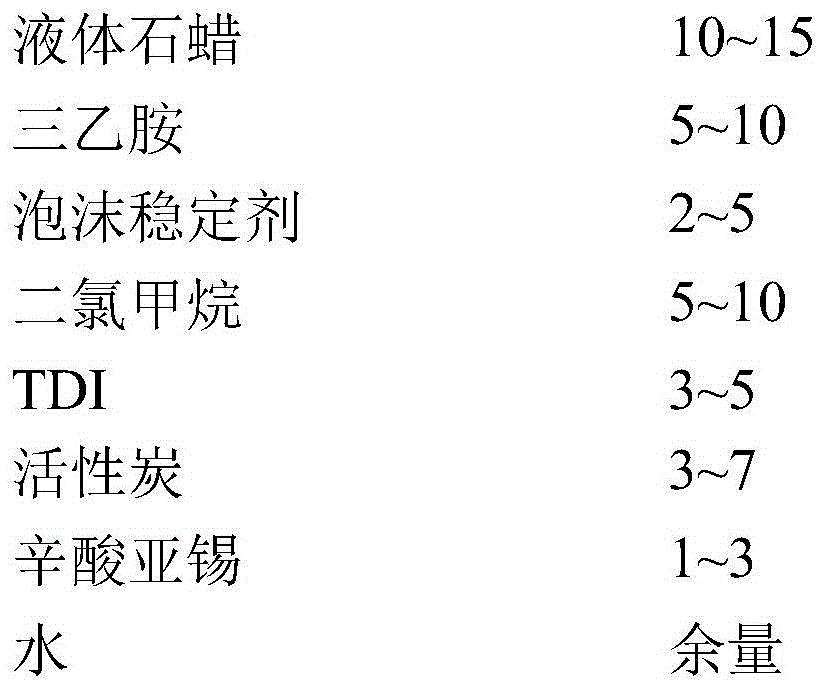

[0024] a filler such as figure 1 As shown, it is a polyurethane foam containing activated carbon powder, and every 100g of raw materials includes the following components through foaming processing:

[0025]

Embodiment 2

[0027] A kind of preparation method of filler comprises the steps:

[0028] Step (1): take polyether, water, liquid paraffin, triethylamine, foam stabilizer and dichloromethane according to the formula of embodiment 1, get the polyether of 10g and water, liquid paraffin, triethylamine, foam stabilizer The mixture was mixed and stirred for 30 minutes, then dichloromethane was added and stirred for 25 minutes to obtain liquid A;

[0029] Step (2): Take TDI, activated carbon and stannous octoate according to the formula of Example 1, and mix the remaining polyether in step (1) with TDI, activated carbon and stannous octoate to obtain liquid B; Control the temperature at 20°C;

[0030] Step (3): Mix liquid A and liquid B, mix and stir at 10,000 rpm for 15 seconds, pour into a foaming mold for foaming, after foaming, it needs to be aged for 25 hours, and the temperature during the aging process is controlled at 20°C .

Embodiment 3

[0032] A kind of filler, it is the polyurethane foam that contains activated carbon powder, and every 100g raw material comprises the component of following quality and is made through foaming process:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com