Exterior wall putty with capacity of energy saving and heat preservation and preparation method

An external wall putty and thermal insulation technology, applied in the direction of filling slurry, etc., can solve the problems of weak adhesion, poor thermal insulation performance, complex formula, etc., and achieve the effect of easy construction, good construction performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

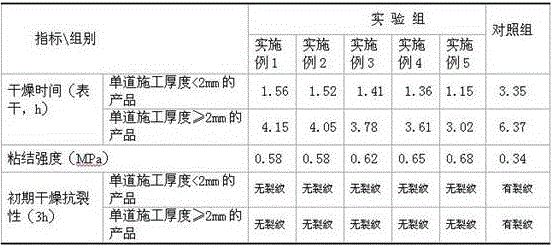

Examples

Embodiment 1

[0042] Example 1 The energy-saving and heat-preserving exterior wall putty is prepared from the following main raw materials (20 kg per part): 36 parts of talcum powder, 16 parts of silicon dioxide, 8 parts of hydroxypropyl methylcellulose, and 5 parts of plant ash , 4 parts of benzoic acid, 3 parts of citric acid, 3 parts of corn starch, 1 part of sawdust, 3 parts of aluminum powder, 4 parts of rubber powder, 4 parts of boric acid, 22 parts of water.

[0043] The steps for preparing energy-saving and heat-preserving exterior wall putty are as follows:

[0044] (1) Heat half of the mass of water to 50°C, add it to the stirring tank, add talcum powder and silicon dioxide, stir evenly, pour it into a reaction kettle with a thermometer, add benzoic acid when it is heated to 140°C, and keep it warm React for 3 hours, cool to room temperature, add sodium hydroxide, adjust pH to 7.2;

[0045] (2) Put the sawdust in a sawdust grinder, crush it mechanically, put it in a mixer, add co...

Embodiment 2

[0050] Example 2 The exterior wall putty capable of energy saving and heat preservation is prepared from the following main raw materials (10 kg for each part): 46 parts of talcum powder, 24 parts of silicon dioxide, 14 parts of hydroxypropyl methylcellulose, and 10 parts of plant ash , 6 parts of benzoic acid, 5 parts of citric acid, 5 parts of cornstarch, 3 parts of sawdust, 6 parts of aluminum powder, 8 parts of rubber powder, 6 parts of boric acid, and 26 parts of water.

[0051] The steps for preparing energy-saving and heat-preserving exterior wall putty are as follows:

[0052] (1) Heat half of the mass of water to 60°C, add it to the stirring tank, add talcum powder and silicon dioxide, stir evenly, pour it into a reaction kettle with a thermometer, add benzoic acid when it is heated to 160°C, and keep it warm React for 4 hours, cool to room temperature, add sodium hydroxide, adjust pH to 7.8;

[0053] (2) Put the sawdust in a sawdust grinder, crush it mechanically, p...

Embodiment 3

[0058] Example 3 The energy-saving and heat-preserving exterior wall putty is prepared from the following main raw materials (15 kg per part): 40 parts of talcum powder, 18 parts of silicon dioxide, 10 parts of hydroxypropyl methylcellulose, and 7 parts of plant ash , 4.5 parts of benzoic acid, 3.5 parts of citric acid, 3.5 parts of cornstarch, 1.5 parts of sawdust, 4 parts of aluminum powder, 5 parts of rubber powder, 4.5 parts of boric acid, and 23 parts of water.

[0059] The steps for preparing energy-saving and heat-preserving exterior wall putty are as follows:

[0060] (1) Heat half of the mass of water to 53°C, add it to the stirring tank, add talc powder and silicon dioxide, stir evenly, pour it into a reaction kettle with a thermometer, add benzoic acid when heating to 145°C, and keep warm React for 3 hours, cool to room temperature, add sodium hydroxide, adjust pH to 7.4;

[0061] (2) Put the sawdust in a sawdust grinder, crush it mechanically, put it in a blender,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com