Cider and brewing technique thereof

A cider and apple technology, applied in the field of winemaking, can solve the problems of being easily affected by external factors, difficult to control production factors, and low clarity of cider, and achieve the effects of short brewing time, less impurities and high clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

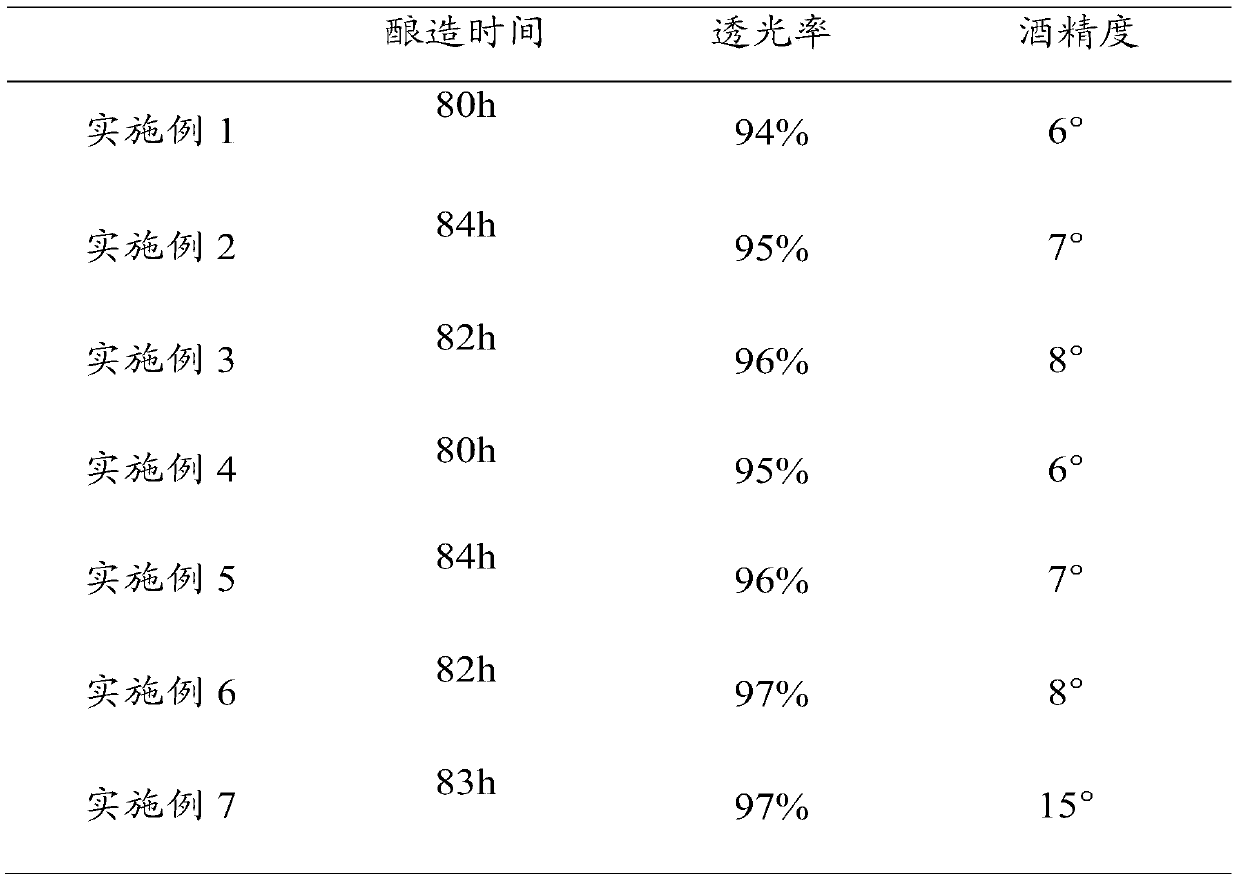

Examples

Embodiment 1

[0053] Embodiment 1 provides a kind of cider, the brewing process of this cider is:

[0054] Select apples that are free from mildew, rot, pests, and green as raw materials, and sterilize and clean the apple raw materials.

[0055] Remove the core and seeds of the processed apples, use a crusher to crush them into 3mm-4mm particles, and pulp the crushed apples.

[0056] Add pectinase to the apple pulp, and stir for 22 hours to obtain clear apple juice by enzymolysis. The amount of pectinase added is 50 mg / L.

[0057] Yeast was added to clear apple juice for fermentation. The amount of yeast added was 0.5g / kg. The fermentation temperature was controlled at 18°C. When no bubbles appeared on the surface of the fermentation liquid, the fermentation was stopped for 22 hours to obtain apple wine.

[0058] Add clarifier to the original apple wine for clarification, and the clarification time is 22 hours to obtain apple wine. The time of the whole brewing process is about 80h.

Embodiment 2

[0060] Embodiment 2 provides a kind of cider, the brewing process of this cider is:

[0061] Select apples that are free from mildew, rot, pests, and green as raw materials, and sterilize and clean the apple raw materials.

[0062] Remove the core and seeds of the processed apples, use a crusher to crush them into 3mm-4mm particles, and pulp the crushed apples.

[0063] Add pectinase to apple pulp and stir for 26 hours to obtain clear apple juice by enzymolysis. The amount of pectinase added is 70 mg / L.

[0064] Yeast was added to clear apple juice for fermentation. The amount of yeast added was 0.8g / kg. The fermentation temperature was controlled at 28°C. When no bubbles appeared on the surface of the fermentation liquid, the fermentation was stopped for 26 hours to obtain apple wine.

[0065] Add clarifier to the original cider for clarification, and the clarification time is 26 hours to obtain cider. The time of the whole brewing process is about 84h.

Embodiment 3

[0067] Embodiment 3 provides a kind of cider, the brewing process of this cider is:

[0068] Select apples that are free from mildew, rot, pests, and green as raw materials, and sterilize and clean the apple raw materials.

[0069] Remove the core and seeds of the processed apples, use a crusher to crush them into 3mm-4mm particles, and pulp the crushed apples.

[0070] Add pectinase to apple pulp and stir for 24 hours to obtain clear apple juice by enzymolysis. The amount of pectinase added is 60 mg / L.

[0071] Yeast was added to clear apple juice for fermentation. The amount of yeast added was 0.6g / kg, and the fermentation temperature was controlled at 23°C. When no bubbles appeared on the surface of the fermentation liquid, the fermentation was stopped. The fermentation time was 24 hours, and the original apple wine was obtained.

[0072] Add clarifier to the original apple wine for clarification, and the clarification time is 24 hours to obtain apple wine. The time of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com