Maca extracting and maca wine producing process

An extraction process and production process technology, which is applied in the field of maca wine production process, can solve problems such as difficult to guarantee product quality, low extraction rate of functional components, damage to product appearance, etc., achieve remarkable clarification effect, ensure sensory quality, and ensure product quality The effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

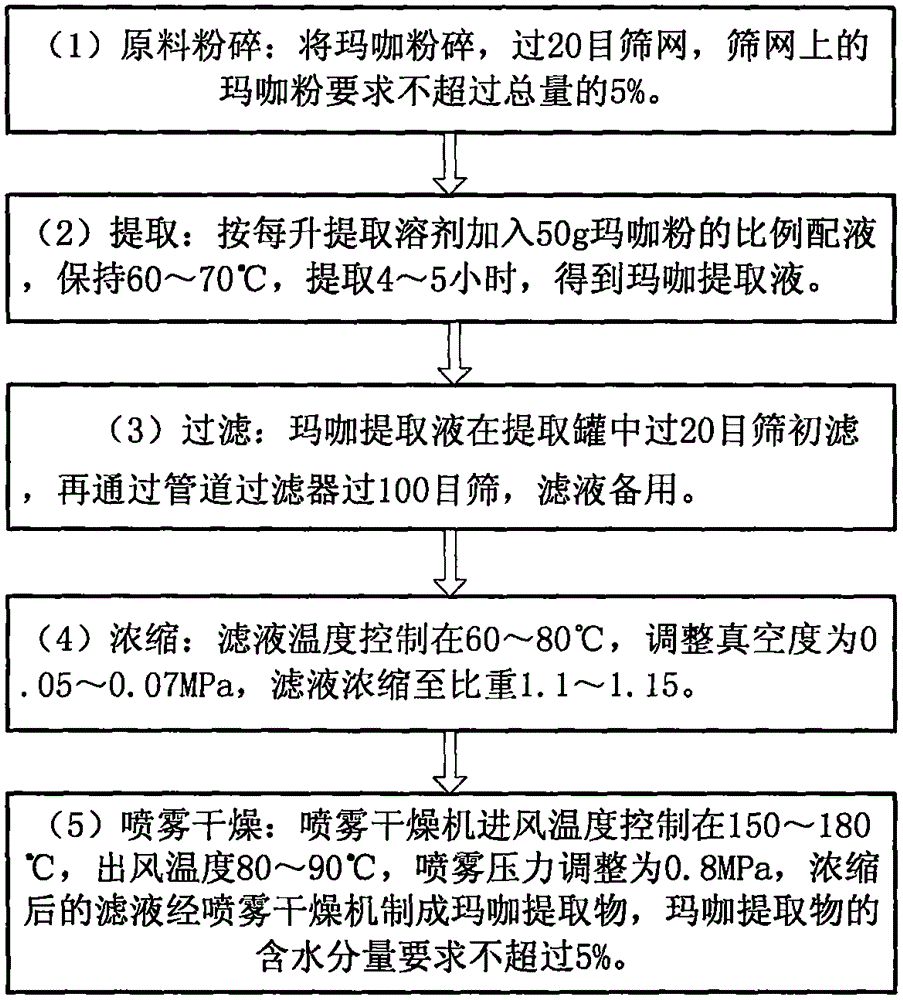

[0022] Embodiment 1: see figure 1 , a Maca extraction process, it comprises the following steps:

[0023] (1) Raw material pulverization: pulverize maca, pass through a 20-mesh sieve, and the maca powder on the sieve requires no more than 5% of the total amount;

[0024] (2) Extraction: Add 50g of maca powder per liter of extraction solvent to prepare liquid, keep at 70°C, extract for 4 hours to obtain maca extract, and the extraction solvent is 60% vol edible alcohol solution;

[0025] (3) Filtration: Maca extract is filtered through a 20-mesh sieve in the extraction tank, then through a pipeline filter through a 100-mesh sieve, and the filtrate is for subsequent use;

[0026] (4) Concentration: the temperature of the filtrate is controlled at 70°C, the vacuum degree is adjusted to 0.05MPa, and the filtrate is concentrated to a specific gravity of 1.1;

[0027] (5) Spray drying: the air inlet temperature of the spray dryer is controlled at 170°C, the air outlet temperature ...

Embodiment 2

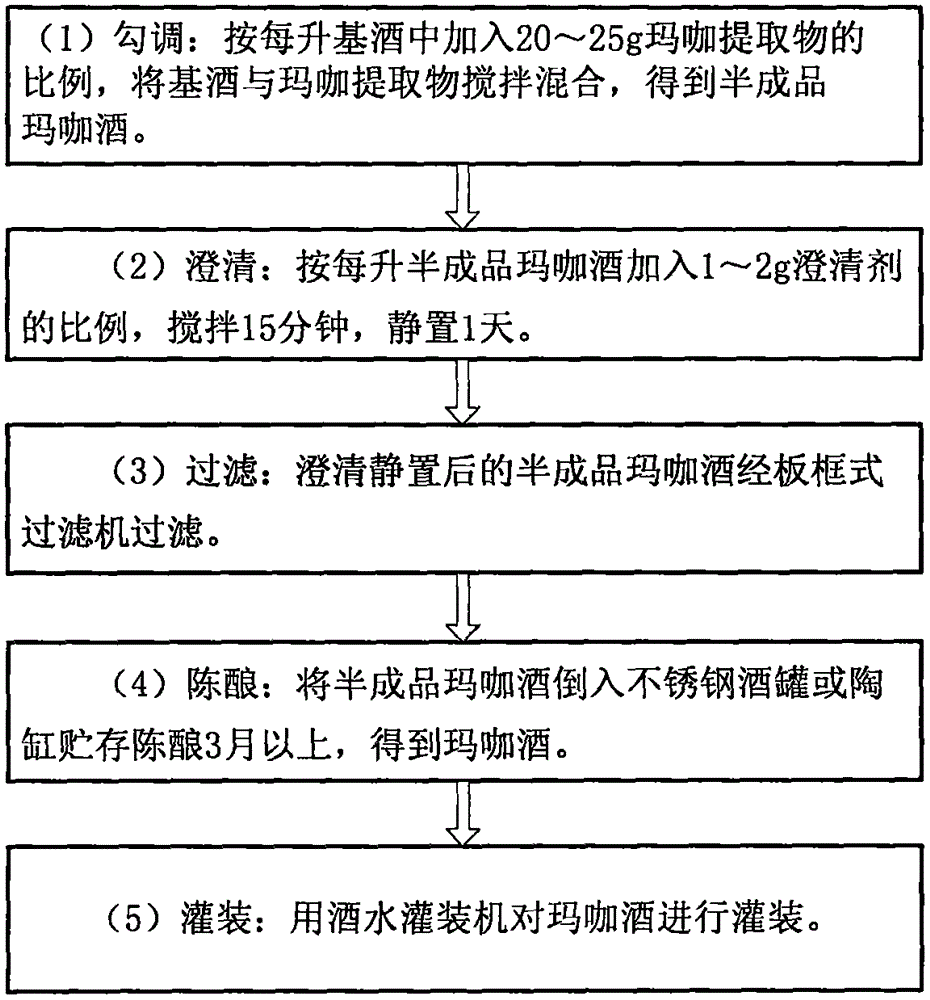

[0028] Example 2: see figure 2 , a Maca wine production process, it uses the Maca extract that embodiment 1 obtains, and it comprises the following steps:

[0029] (1) Blending: according to the ratio of adding 20g of maca extract per liter of base wine, the base wine and the maca extract are stirred and mixed to obtain a semi-finished maca wine. Liquor;

[0030] (2) Clarification: Add 1.5g of egg white liquid per liter of semi-finished maca wine, stir for 15 minutes, and let stand for 1 day;

[0031] (3) Filtration: the semi-finished maca wine after clarifying and standing is filtered through a plate and frame filter;

[0032] (4) Aging: Pour the semi-finished Maca wine into a stainless steel wine tank for storage and aging for 6 months to obtain Maca wine;

[0033] (5) Filling: Fill the maca wine with a wine filling machine.

[0034] The maca extract produced by above-mentioned embodiment 1 is to the extraction rate of total saponins and alkaloids in the maca raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com