Graphene-containing composite polyester fiber and its preparation method and use

A technology of composite polyester and polyester fiber, which is applied in the field of composite polyester, can solve the problems of high environmental protection production pressure, high production cost, and simplification of product functions, and achieve the effect of improving stability and ensuring permanence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] Preparation of carbon nanostructured composites

[0079] (1) Referring to CN104016341A index porous cellulose is specifically:

[0080] At 90°C, use sulfuric acid to adjust the corncob aqueous solution to pH=3, soak for 10 minutes to hydrolyze to obtain lignocellulose, the mass of the sulfuric acid is 3% of the mass of the corncob; then, at 70°C, the obtained The lignocellulose is soaked in the acidic sulfite for 1h to obtain the porous cellulose; wherein, the acid is sulfuric acid, the sulfite is magnesium sulfite, and the quality of the sulfuric acid is 4% of the quality of the lignocellulose, liquid-solid The ratio is 2:1; it is ready for later use;

[0081] (2) preparing carbon nanostructure composites, specifically:

[0082] Mix porous cellulose and catalyst at a mass ratio of 1:0.1-10, stir at 150-200°C for catalytic treatment for more than 4 hours, dry the precursor until the moisture content of the precursor is below 10wt%, and obtain the precursor; then, in a...

Embodiment 1

[0091] A composite polyester fiber is prepared by the following method:

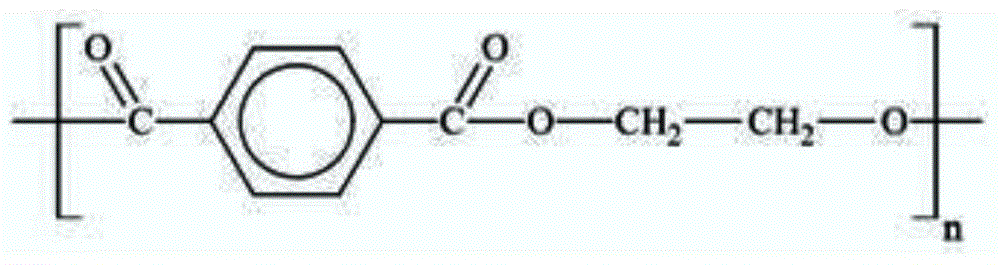

[0092] (1) Mix 100g of carbon nanostructured composites with 8.52kg of PTA and 3.5L of ethylene glycol. After ball milling for 20 minutes, it is directly introduced into the beating kettle for beating for 30 minutes. The reaction is carried out according to the three-pot PET polymerization process, and the polymerization reaction is carried out. After the polymerization reaction is completed, a melt is obtained;

[0093] (2) The melt is discharged under the conditions of cooling water at 40°C and a drawing speed of 0.5m / s, and is directly granulated to obtain a composite PET masterbatch with a carbon nanostructure;

[0094] (3) After drying the composite PET masterbatch of carbon nanostructure at 110°C for 24 hours on a drum, it is directly used for melt spinning, and the spinning is cooled by water mist, the cooling temperature is 40°C, and the drying temperature is 35°C. ℃, melt spinning to obtain com...

Embodiment 2

[0100] A composite polyester fiber is prepared by the following method:

[0101] (1) Mix 200g of carbon nanostructured composites with 8.52kg of PTA and 3.5L of ethylene glycol. After ball milling for 20 minutes, it is directly introduced into the beating kettle for beating for 30 minutes. The reaction is carried out according to the three-pot PET polymerization process, and the polymerization reaction is carried out. After the polymerization reaction is completed, a melt is obtained;

[0102] (2) The melt is discharged under the conditions of cooling water at 40°C and a drawing speed of 0.5m / s, and is directly granulated to obtain a composite PET masterbatch with a carbon nanostructure;

[0103] (3) After drying the composite PET masterbatch of carbon nanostructure at 110°C for 24 hours on a drum, it is directly used for melt spinning, and the spinning is cooled by water mist, the cooling temperature is 40°C, and the drying temperature is 35°C. ℃, melt spinning to obtain com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com