Electroporation disinfecting device, method and application of nanowire modified three-dimensional electrodes

A technology of three-dimensional electrodes and disinfection devices, applied in chemical instruments and methods, magnetic/electric field water/sewage treatment, special treatment targets, etc., can solve problems such as long hydraulic retention time, large floor space, limited resurrection, etc., to achieve Guarantee the safety of water, ensure the safety of effluent, and the effect of safe disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

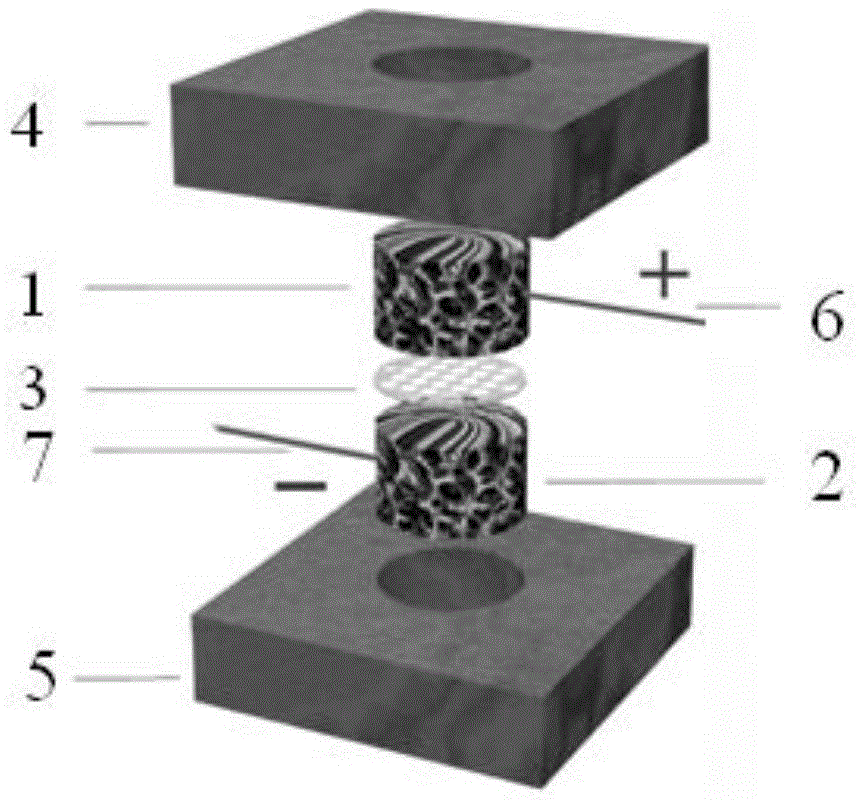

[0023] use figure 1 The device shown, undergoes nanowire-modified 3D electrode electroporation for disinfection. A cylindrical porous copper foam electrode with a diameter of 10mm and a thickness of 5mm was heated at 350-450°C for 1-3h to prepare a three-dimensional electrode decorated with copper oxide nanowires; two three-dimensional electrodes decorated with copper oxide nanowires were respectively fixed on two In an insulating groove, ensure that the distance between two copper oxide nanowire-modified three-dimensional electrodes is greater than 5mm to prevent contact short circuit, and place a layer of plastic mesh to ensure safety.

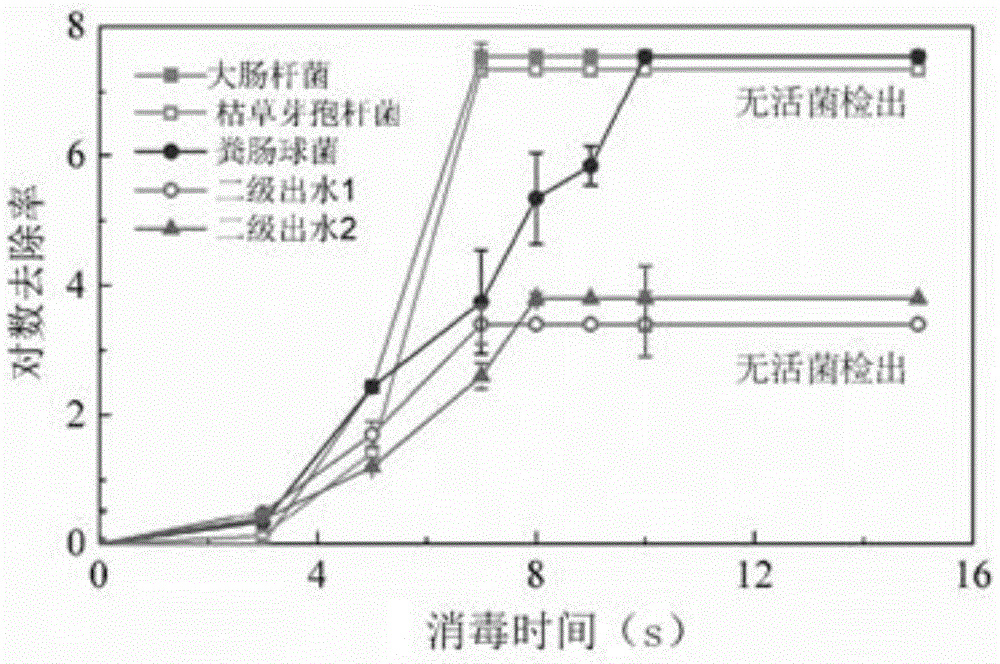

[0024] Escherichia coli (ATCC15597), Enterococcus faecalis (ATCC19433) and Bacillus subtilis (ATCC6633) were used as model bacteria, and the model bacteria in the logarithmic phase were enriched and cultured for 12 hours, and normal saline (9g / L sodium chloride solution ) diluted to a bacterial concentration of approximately 10 7 cells / mL ...

Embodiment 2

[0025] use figure 1 The device shown, undergoes nanowire-modified 3D electrode electroporation for disinfection. A cylindrical porous copper foam electrode with a diameter of 10mm and a thickness of 5mm was heated at 350-450°C for 1-3h to prepare a three-dimensional electrode decorated with copper oxide nanowires; two three-dimensional electrodes decorated with copper oxide nanowires were respectively fixed on two In an insulating groove, ensure that the distance between two copper oxide nanowire-modified three-dimensional electrodes is greater than 5mm to prevent contact short circuit, and place a layer of plastic mesh to ensure safety. The two three-dimensional electrodes decorated with copper oxide nanowires are respectively connected to the positive and negative electrodes of the power supply through wires, and the power switch is turned on so that the treated water passes through the three-dimensional electrodes decorated with copper oxide nanowires to achieve efficient d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com