Dendritic cellulose-based amphoteric flocculating-decolorizing agent and preparation method thereof

A cellulose-based, decolorizing agent technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor treatment effect, small application range, environmental and human hazards, etc., and achieve high flocculation decolorization efficiency and large capacity decolorization In addition, there is no effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 0.5 g of sodium carboxymethyl cellulose to 40 mL of distilled water, and stir magnetically at room temperature to obtain a uniform and transparent sodium carboxymethyl cellulose solution;

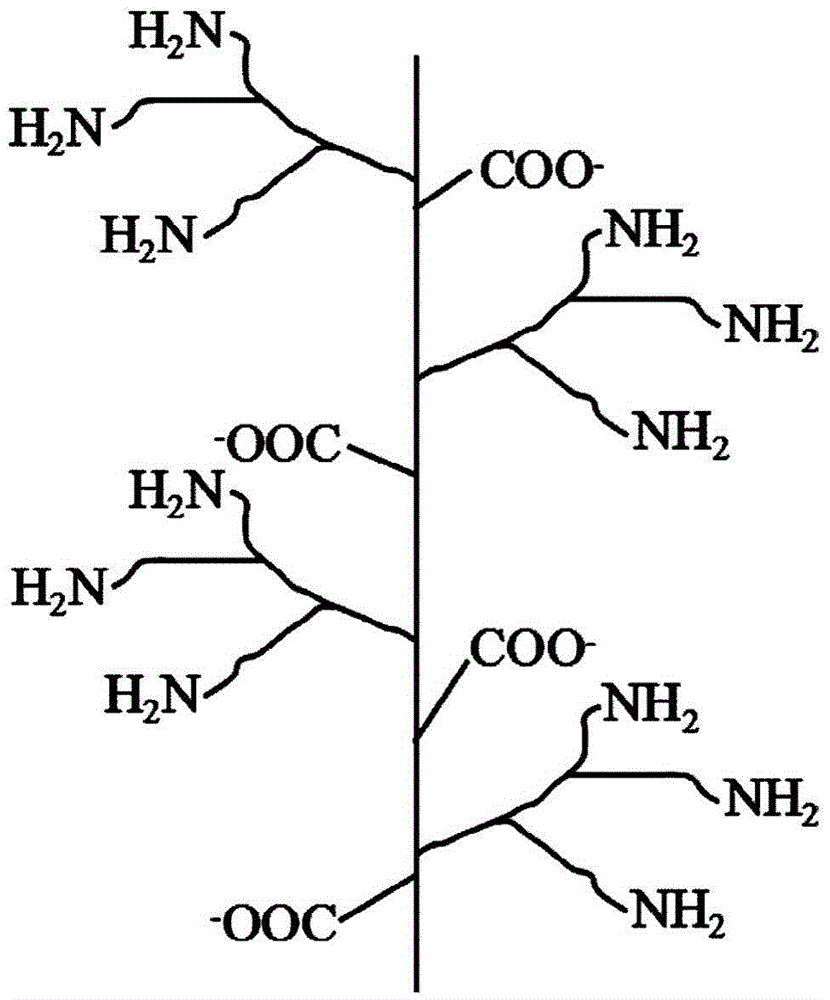

[0031] (2) Add 0.25 g of sodium periodate to the sodium carboxymethyl cellulose solution obtained in step (1) under magnetic stirring, and oxidize it at 35°C for 120 min; The mass ratio of sodium is 0.5:1, polyethyleneimine with a molecular weight of 600 is added, and the grafting reaction takes 120 minutes to obtain a uniform and transparent solution;

[0032] (3) The solution obtained in step (2) was added to 5 times the volume of absolute ethanol, and the mixture was centrifuged at 8000 rpm for 5 minutes to collect the precipitate, which was washed and dried by centrifugation to obtain a dendritic cellulose-based amphoteric flocculant.

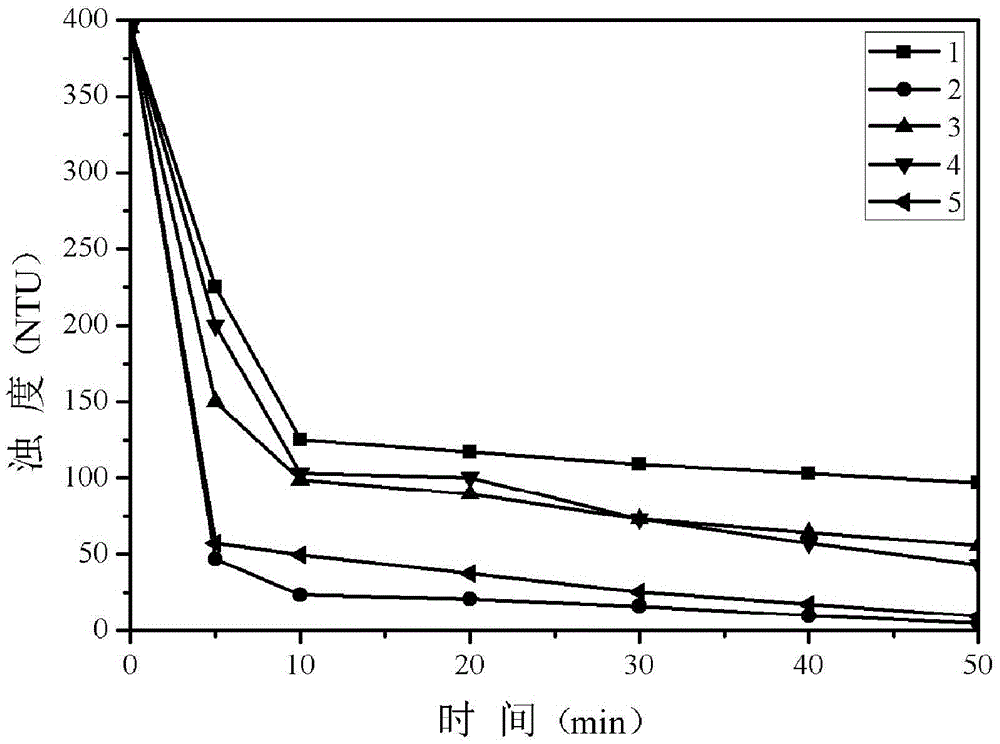

[0033] The flocculation decolorizing agent prepared in this example forms a solution with a concentration of 2g / L, and presents different...

Embodiment 2

[0035] (1) Add 0.5 g of pulp pulp into 50 mL of distilled water, and stir magnetically at room temperature to obtain a uniformly dispersed cellulose suspension;

[0036] (2) Add 0.5g of sodium periodate to the cellulose suspension obtained in step (1) under magnetic stirring, and oxidize it for 120min at 50°C; then the mass ratio of polyethyleneimine to pulp is 1: 1. Add polyethyleneimine with a molecular weight of 3000 and graft for 150 minutes to obtain a uniform and transparent solution;

[0037] (3) The solution obtained in step (2) was added to 5 times the volume of absolute ethanol, and the mixture was centrifuged at 8000 rpm for 5 minutes to collect the precipitate, which was washed and dried by centrifugation to obtain a dendritic cellulose-based amphoteric flocculant.

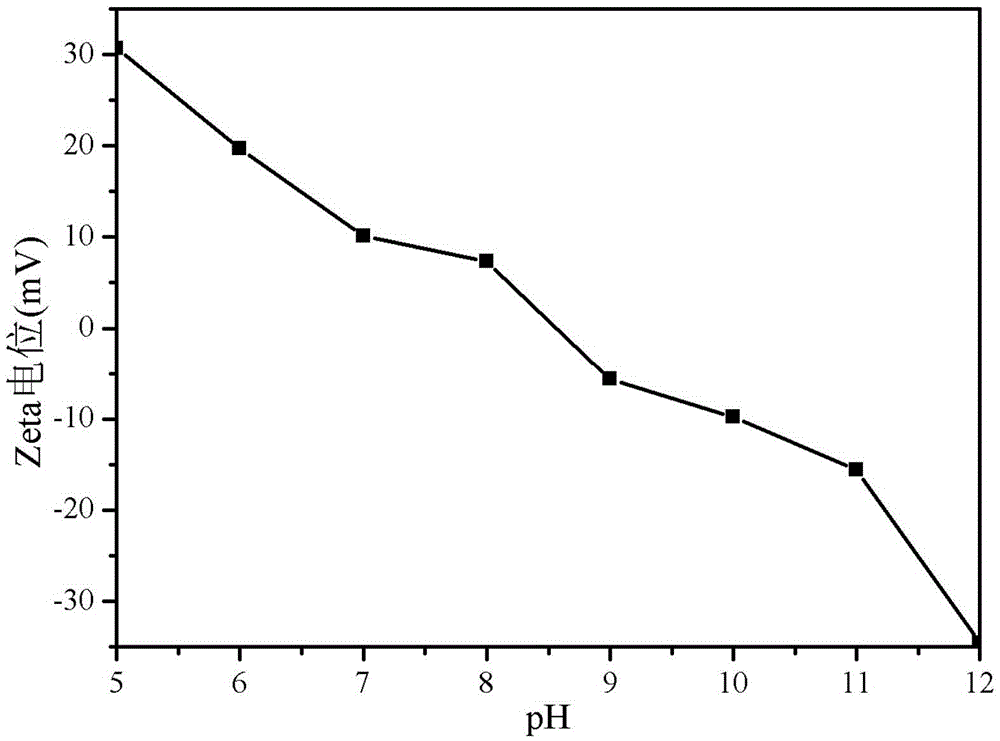

[0038] The flocculation decolorizing agent prepared in this example forms a solution with a concentration of 2g / L, and presents different surface charge characteristics at different pHs, such as imag...

Embodiment 3

[0040] (1) Add 0.5 g of wood pulp into 60 mL of distilled water, and stir magnetically at room temperature to obtain a uniformly dispersed cellulose suspension;

[0041] (2) Add 0.5 g of sodium periodate into the cellulose suspension obtained in step (1) under the action of magnetic stirring, and oxidize it for 180 min at 50° C.; : 1, adding molecular weight is the polyethylenimine of 3500, grafting reaction 180min, obtains uniform cellulose suspension;

[0042] (3) The solution obtained in step (2) was added to 5 times the volume of absolute ethanol, and the mixture was centrifuged at 8000 rpm for 5 minutes to collect the precipitate, which was washed and dried by centrifugation to obtain a dendritic cellulose-based amphoteric flocculant.

[0043] The flocculation decolorizing agent prepared in this example forms a solution with a concentration of 2g / L, and presents different surface charge characteristics at different pHs, such as image 3 As shown, its Zeta potential range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com