Biofilter purification method for residual phase after toluene extraction of benzoic acid production waste water

A technology for producing wastewater and biological filter beds, which is applied in chemical instruments and methods, multi-stage water treatment, water treatment parameter control, etc. Get convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of benzoic acid production wastewater toluene raffinate biological filter bed purification method, comprises the following steps:

[0042] ⑴. Deploying benzoic acid production wastewater toluene raffinate phase wastewater and domestic sewage to form a mixed solution;

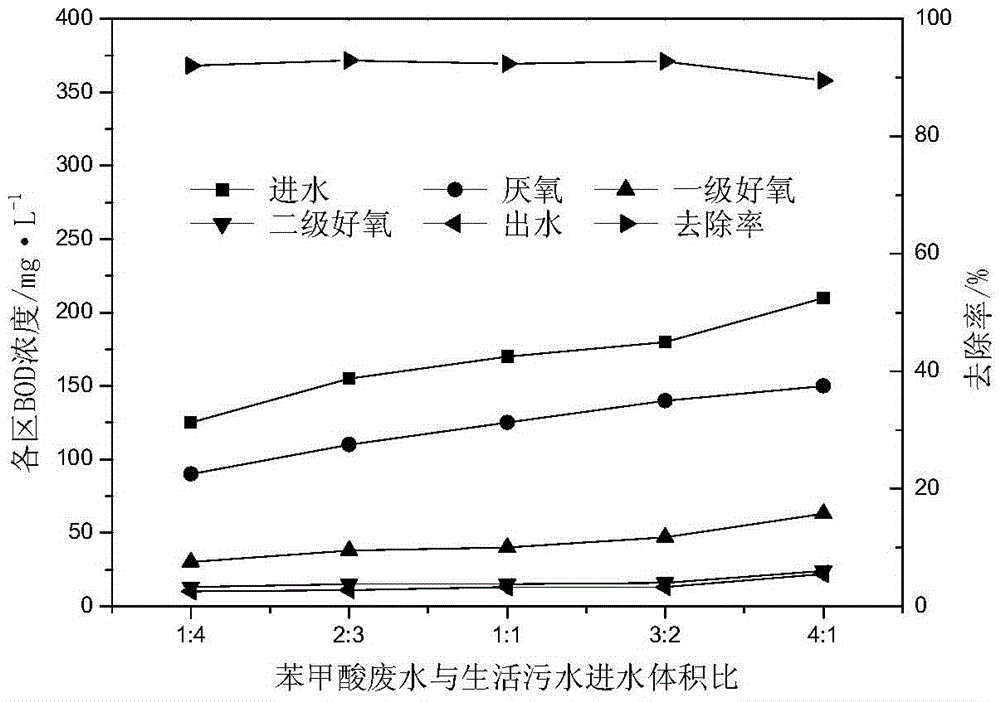

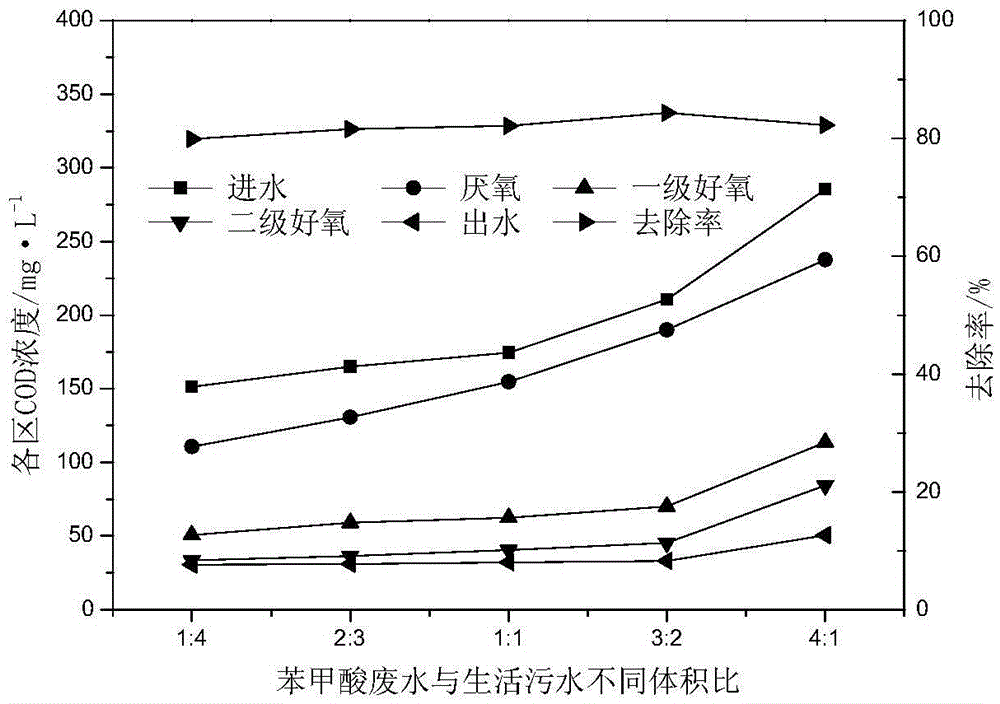

[0043] Described benzoic acid production waste water toluene raffinate phase waste water is the benzoic acid waste water after twice extraction of toluene, and the volume ratio Vb:Vs of benzoic acid production waste water toluene raffinate phase waste water and domestic sewage is 1:4;

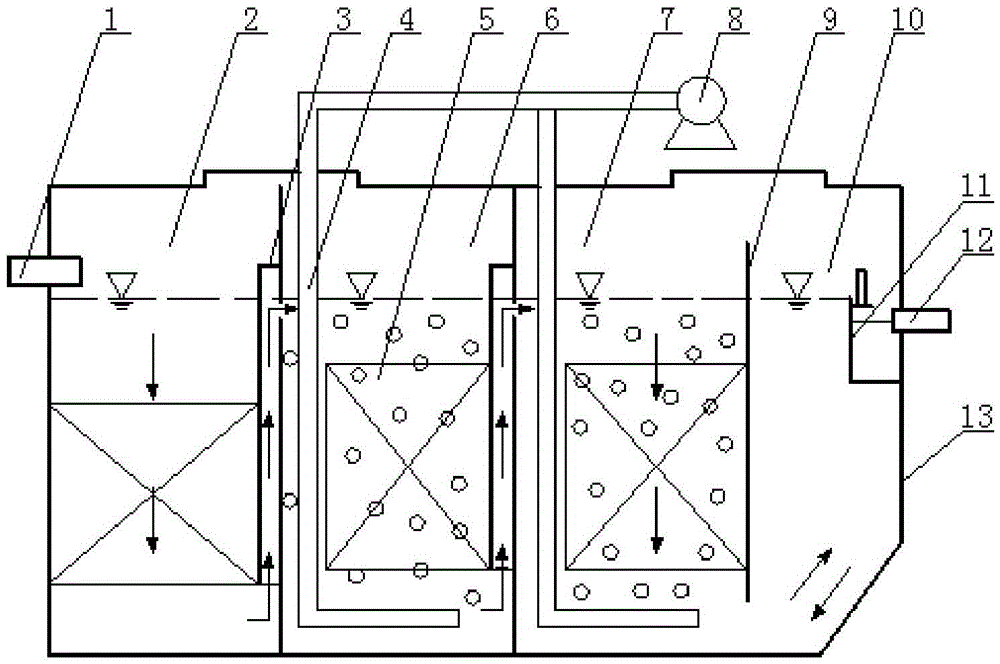

[0044] ⑵. Send the prepared mixed solution into the multi-functional new purification tank. The mixed solution first undergoes one-stage anaerobic acidification hydrolysis treatment, then two-stage aerobic treatment, and finally precipitation disinfection treatment, and finally the multi-functional new purification tank Discharge in the middle is to complete the purification process. The purification method adopts ...

Embodiment 2

[0050] A kind of benzoic acid production wastewater toluene raffinate biological filter bed purification method, comprises the following steps:

[0051] ⑴. Deploying benzoic acid production wastewater toluene raffinate phase wastewater and domestic sewage to form a mixed solution;

[0052] Described benzoic acid production waste water toluene raffinate phase waste water is the benzoic acid waste water after twice extraction of toluene, and the volume ratio Vb:Vs of benzoic acid production waste water toluene raffinate phase waste water and domestic sewage is 2:3;

[0053] ⑵. Send the prepared mixed solution into the multi-functional new purification tank. The mixed solution first undergoes one-stage anaerobic acidification hydrolysis treatment, then two-stage aerobic treatment, and finally precipitation disinfection treatment, and finally the multi-functional new purification tank Discharge in the middle is to complete the purification process. The purification method adopts ...

Embodiment 3

[0056] A kind of benzoic acid production wastewater toluene raffinate biological filter bed purification method, comprises the following steps:

[0057] ⑴. Deploying benzoic acid production wastewater toluene raffinate phase wastewater and domestic sewage to form a mixed solution;

[0058] Described benzoic acid production waste water toluene raffinate phase waste water is the benzoic acid waste water after twice extraction of toluene, and the volume ratio Vb:Vs of benzoic acid production waste water toluene raffinate phase waste water and domestic sewage is 1:1;

[0059] ⑵. Send the prepared mixed solution into the multi-functional new purification tank. The mixed solution first undergoes one-stage anaerobic acidification hydrolysis treatment, then two-stage aerobic treatment, and finally precipitation disinfection treatment, and finally the multi-functional new purification tank Discharge in the middle is to complete the purification process. The purification method adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com