Synthetic method for ocean natural product Haterumadienone

A technology of natural products and synthetic methods, applied in the production of bulk chemicals, organic chemistry, etc., to achieve the effects of high total yield, fewer reaction steps, and good product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

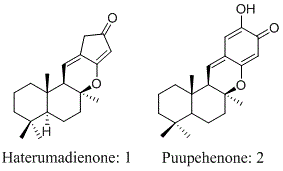

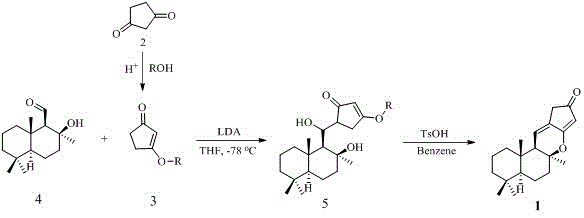

[0018] Embodiment 1: Cyclopentanedione (3, see attached figure 2 )Synthesis

[0019] Dissolve 0.98 g (2, 10.0 mmol) of cyclopentanedione in 25 ml of absolute ethanol, add hydrochloric acid (1 mmol), stir and react at room temperature for 3 hours, and TLC detects that the reaction is complete. Add 30 ml of water, extract with dichloromethane (30mLx3), combine the organic phases, wash with saturated sodium bicarbonate solution, dry over anhydrous sodium sulfate, filter, concentrate, and purify by column chromatography to obtain a light yellow oily substance ethoxy-protected ring Pentanedione 1.07 grams, yield is 85%.

Embodiment 2

[0020] Embodiment 2: beta-hydroxycyclopentanone (5, see attached figure 2 )Synthesis

[0021] Dissolve 126 mg (3, 1.0 mmol) of ethoxy-protected cyclopentanedione in 2 ml of anhydrous tetrahydrofuran, repeatedly fill and exhaust argon three times, exhaust the air, and cool down to -78 o c. LDA (3 mmol) was added and the reaction was kept stirring at this temperature for 30 minutes. Another 238 mg (-) sclarealdehyde (4, 1.0 mmol) was dissolved in 1 ml of anhydrous tetrahydrofuran, and slowly added dropwise to the above reaction system, and the stirring reaction was continued for 12 hours, and the reaction was detected by TLC. 5 ml of saturated ammonium chloride solution was added dropwise to the reaction system to quench the reaction, and stirring was continued at room temperature for 30 minutes. Extract with ethyl acetate (10mLx3), combine the organic phases, wash with saturated brine, dry over anhydrous sodium sulfate, filter, concentrate, and purify by column chromatograp...

Embodiment 3

[0022] Embodiment 3: Haterumadienone (1, see attached figure 2 )Synthesis

[0023] Dissolve 182 mg (5,0.5 mmol) of beta-hydroxycyclopentanone of dicyclic sesquiterpene in 2 ml of benzene, add p-toluenesulfonic acid (0.5 mmol), stir and react at room temperature for 3 hours, and TLC detects that the reaction is complete. Add 10 ml of ethyl acetate, wash with saturated brine (10 mL x 3), dry the organic phase over anhydrous sodium sulfate, filter, concentrate, and purify by column chromatography to obtain 105 mg of a light yellow solid with a yield of 70%. Optical rotation [α] D 25 -73.6°(c=0.15, CHCl 3 ); H NMR spectrum 1 HNMR (400MHz, C 6 D. 6 )σ5.61(s,1H),5.28(d,1H),2.83(d,1H),2.75(d,1H),1.96(td,1H),1.36(m,1H),1.31(m,2H ),1.26(m,1H),1.25(m,2H),1.03(dt,1H),0.95(s,3H),0.80(s,3H),0.74(s,3H),0.5(s,3H) ,0.67(dt,1H),0.67(dd,1H); C NMR 13 CNMR (75MHz, C 6 D. 6 )σ199.2, 177.9, 132.9, 121.2, 110.1, 80.1, 53.8, 53.7, 41.8, 39.8, 39.4, 39.4, 37.8, 33.6, 33.1, 28.5, 22.0, 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com