Silicon-containing flame retardant polyether surface treating agent as well as preparation method and application thereof

A technology of surface treatment agent and flame retardant polyether, which is applied in the field of silicon-containing flame retardant polyether surface treatment agent and its preparation, can solve the problem of no flame retardant function, poor compatibility between the treatment agent and polyurethane, and inability to use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step (1). Mix polyether polyol with an average molecular weight of 300 and a functionality of 2 with triethylamine at a molar ratio of 1:2, and stir at 40°C for 0.5 hour in a nitrogen atmosphere to obtain a polyether polyol with a functionality of 2. Active hydrogen compounds of polyether polyols;

[0024] Step (2). Under the condition of continuous stirring, the active hydrogen compound of the polyether polyol with a functionality of 2 in the step (1) is added dropwise to the tetrahydrofuran solvent whose concentration of phenyl dichlorophosphate is 0.1mol / L, Make the molar ratio of phenyl dichlorophosphate and polyether polyol in the solution to be 2.1:1, add dropwise for 30 minutes, and react at 40°C for 5 hours;

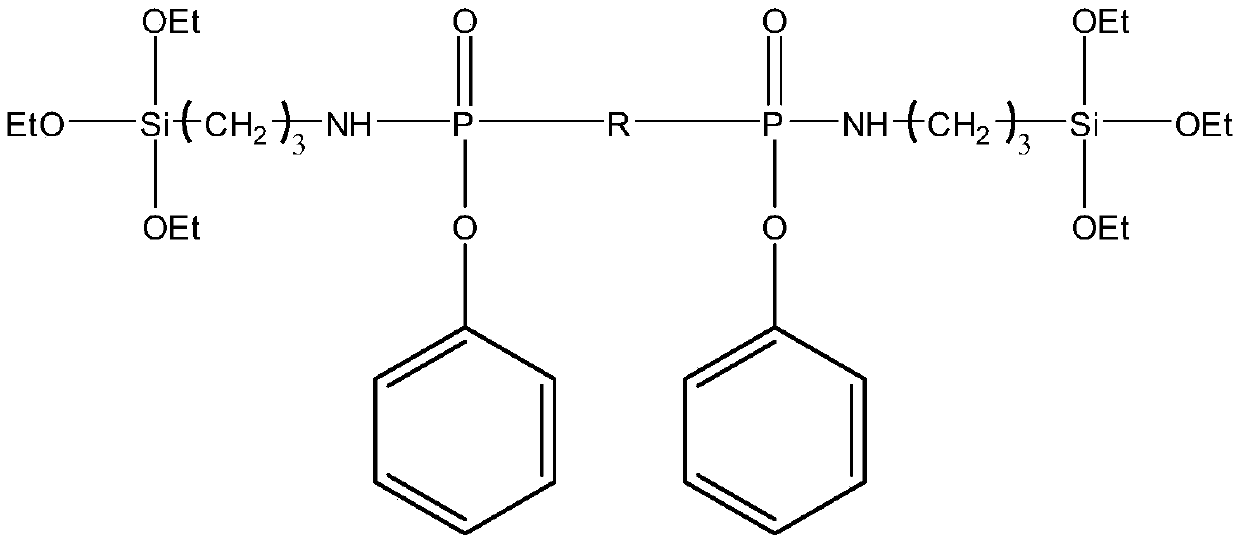

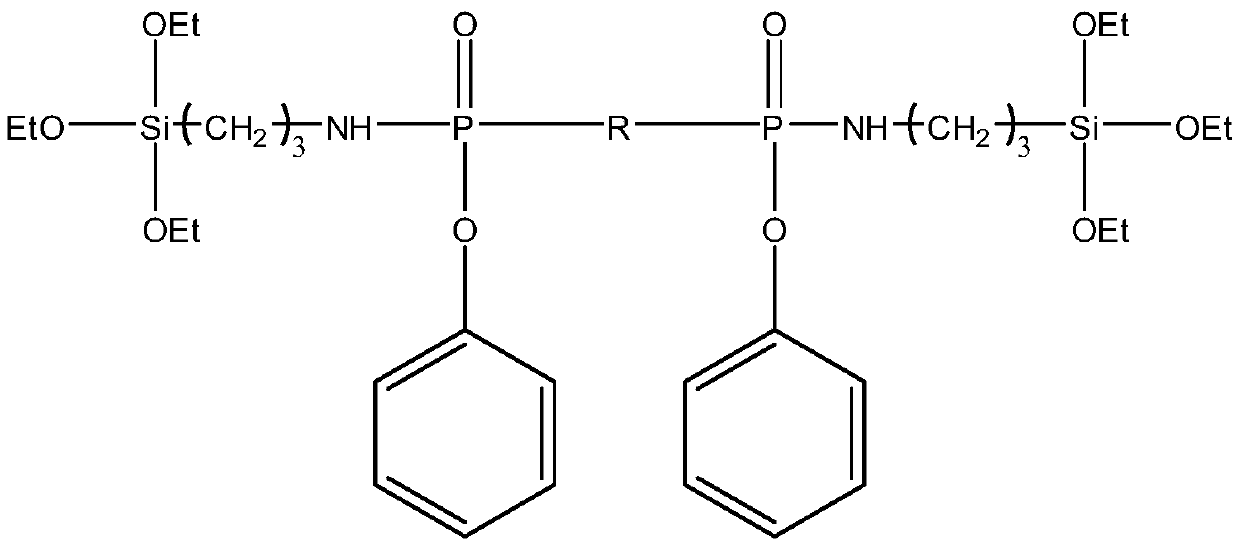

[0025] Step (3). Add γ-aminopropyltriethoxysilane to the reaction solution, so that the molar ratio of γ-aminopropyltriethoxysilane and polyether polyol in the solution is 2.1:1, and then add three Ethylamine, make the mol ratio of triethylamine and gamma...

Embodiment 2

[0029] Step (1). Mix polyether polyol with an average molecular weight of 4000 and a functionality of 2 with triethylamine at a molar ratio of 1:2, and stir at 80°C for 0.5 hours in nitrogen to obtain a polyol with a functionality of 2. Active hydrogen compounds of ether polyols.

[0030] Step (2). Under the condition of continuous stirring, the active hydrogen compound of the polyether polyol with a functionality of 2 in the step (1) is added dropwise to the dioxane solvent whose concentration of phenyl dichlorophosphate is 1mol / L In the process, the molar ratio of phenyl dichlorophosphate to polyether polyol is 2.5:1, the time for dropping is 90 minutes, and the reaction is carried out at 80° C. for 10 hours;

[0031] Step (3). Add γ-aminopropyltriethoxysilane to the reaction solution, so that the molar ratio of γ-aminopropyltriethoxysilane and polyether polyol in the solution is 2.5:1, and then add three Ethylamine, making the mol ratio of triethylamine and γ-aminopropyltr...

Embodiment 3

[0035] Step (1). Mix the polyether polyamine with an average molecular weight of 1000 and a functionality of 2 with triethylamine at a molar ratio of 1:2, and stir at 50°C for 0.6 hours in a nitrogen atmosphere to obtain a polyether polyamine with a functionality of 2. Active hydrogen compounds of polyether polyamines.

[0036] Step (2). Under the condition of continuous stirring, the active hydrogen compound of the polyether polyamine with a functionality of 2 in the step (1) is added dropwise to the concentration of phenyl dichlorophosphate in the acetone solvent of 0.5mol / L, so that The molar ratio of phenyl dichlorophosphate to polyether polyamine is 2.3:1; the dropping time is 60 minutes, and the reaction is 7 hours at 50°C;

[0037] Step (3). Add γ-aminopropyltriethoxysilane to the reaction solution, so that the molar ratio of γ-aminopropyltriethoxysilane and polyether polyol in the solution is 2.3:1, and then add three Ethylamine, making the mol ratio of triethylamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com