Preparation method of polyamide polyether organosilicone ternary polymerization type hydrophilic finishing agent

A technology of silicon ternary copolymerization and hydrophilic finishing agent, which is applied in fiber treatment, improved hand-feeling fiber, textiles and papermaking, etc. It can solve the problems that cannot meet the needs of industrialization, it is not easy to promote industrialization, and the production environment requires high requirements. High economic benefits and industrial promotion prospects, excellent hand feeling quality, and the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

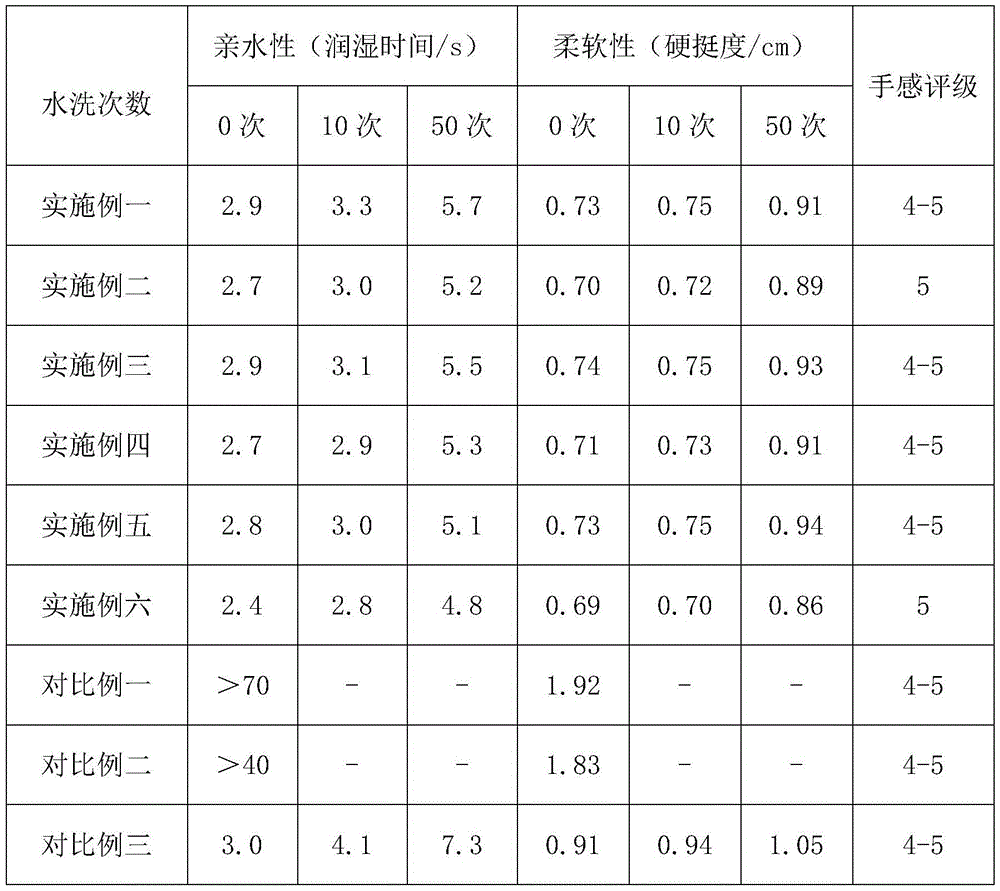

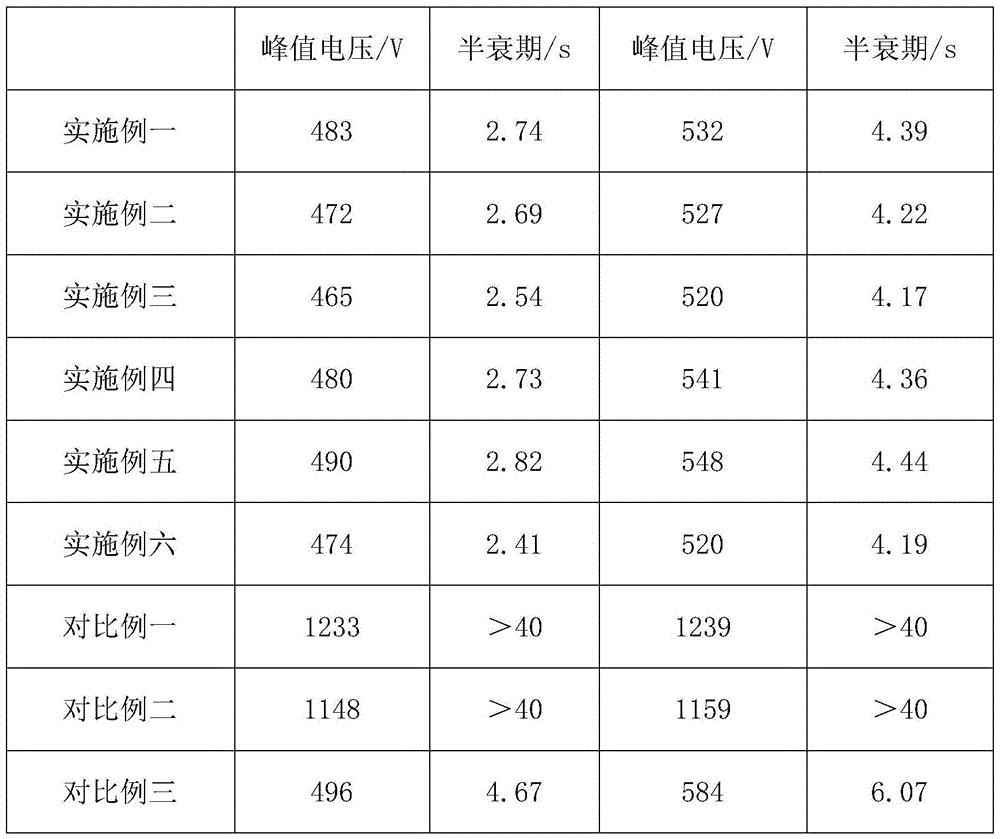

Examples

Embodiment 1

[0032] A preparation method of a polyamide polyether silicone ternary copolymerization type hydrophilic finishing agent, with hexamethylenediamine, adipic acid, double-terminal carboxyl polyethylene glycol and double-terminal amino polyether silicone oil according to the ratio of the amount of substances 1: 5:2:0.8 Mix evenly, pass nitrogen protection, slowly heat up to 200°C, keep warm for 15 minutes;

[0033] Add 1.5% of phosphorous acid and 0.5% of manganese dioxide solid in the total mass of the mixture of hexamethylenediamine, adipic acid, double-ended carboxyl polyethylene glycol and double-ended amino polyether silicone oil, and heat up to 270°C for normal compression polymerization for 1.5 h;

[0034] Add phosphorous acid and other solid sodium chloride, slowly stir and cool down to 100 degrees Celsius, and remove the water layer after standing to separate layers to obtain a polyamide polyether silicone ternary copolymerization type hydrophilic finishing agent.

[003...

Embodiment 2

[0038] A preparation method of a polyamide polyether silicone ternary copolymerization type hydrophilic finishing agent, with hexamethylenediamine, adipic acid, double-terminal carboxyl polyethylene glycol and double-terminal amino polyether silicone oil according to the ratio of the amount of substances 1: Mix 5:3:1 evenly, pass nitrogen protection, slowly heat up to 200°C, and keep warm for 25 minutes;

[0039] Add hexamethylenediamine, adipic acid, double-terminated carboxyl polyethylene glycol and double-terminated amino polyether silicone oil mixture, 1.5% of phosphorous acid and 1% of manganese dioxide solid, and heat up to 300°C for normal compression polymerization for 2 hours ;

[0040] Add phosphorous acid and other solid sodium chloride, slowly stir and cool down to 100 degrees Celsius, and remove the water layer after standing to separate layers to obtain a polyamide polyether silicone ternary copolymerization type hydrophilic finishing agent.

[0041] The polyami...

Embodiment 3

[0044] A preparation method of a polyamide polyether silicone ternary copolymerization type hydrophilic finishing agent, with hexamethylenediamine, adipic acid, double-terminal carboxyl polyethylene glycol and double-terminal amino polyether silicone oil according to the ratio of the amount of substances 1: Mix 5:2:1 evenly, pass nitrogen protection, slowly heat up to 200°C, and keep warm for 15 minutes;

[0045] Add 1.5% of phosphorous acid and 0.5% of manganese dioxide solid in the total mass of the mixture of hexamethylenediamine, adipic acid, double-ended carboxyl polyethylene glycol and double-ended amino polyether silicone oil, and heat up to 300°C for normal compression polymerization for 1.5 h;

[0046] Add phosphorous acid and other solid sodium chloride, slowly stir and cool down to 100 degrees Celsius, and remove the water layer after standing to separate layers to obtain a polyamide polyether silicone ternary copolymerization type hydrophilic finishing agent.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com