Master batch for plastic film products and manufacturing method of master batch

A technology of a plastic film and a manufacturing method, applied in the field of plastic masterbatch, can solve the problems of different particle sizes, slag removal, discoloration, etc., and achieve the effects of avoiding oxidation reaction, improving weather resistance, and improving application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

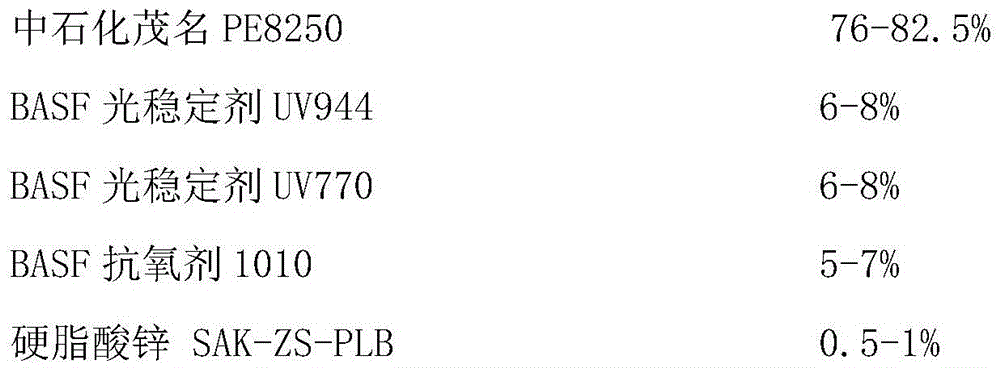

[0016] A masterbatch for plastic film products, its composition and corresponding weight percentage are as follows:

[0017]

[0018] The described manufacture method of the masterbatch that is used for plastic film product, comprises the following steps:

[0019] a. Weighing: Carrier powder PE8250, light stabilizer UV944, light stabilizer UV770, antioxidant 1010, zinc stearate SAK-ZS-PLB are weighed according to the proportion.

[0020] b. Stirring: Put the carrier and additives into the high mixer and stir in turn. The amount of the mixed material should not exceed 2 / 3 of the volume, the speed is 10-20Hz, and the mixing time is 15 minutes.

[0021] c. Pelletizing: put the compounded mixture into the extruder, and cut the pellets through the pelletizer after the material is discharged from the die.

[0022] d. Screening: The cut particles are passed through a vibrating sieve, and the masterbatch with uniform size is screened out for packaging.

Embodiment 2

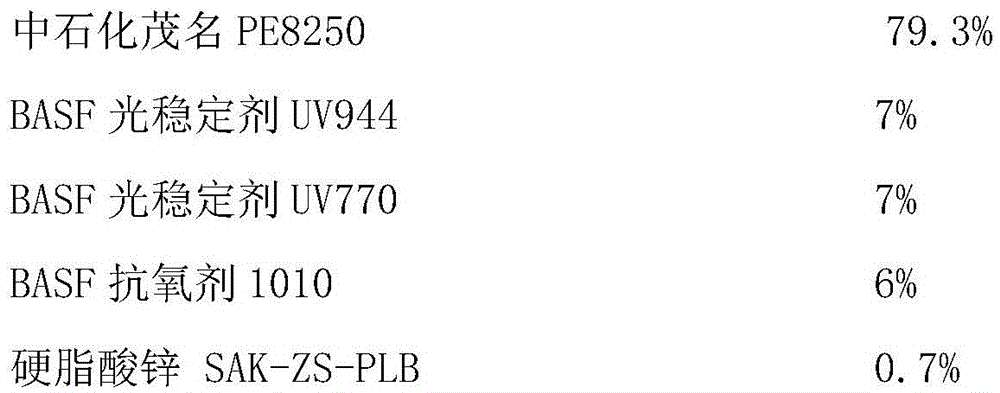

[0024] A masterbatch for plastic film products, its composition and corresponding weight percentage are as follows:

[0025]

[0026] The described manufacture method of the masterbatch that is used for plastic film product, comprises the following steps:

[0027] a. Weighing: Carrier powder PE8250, light stabilizer UV944, light stabilizer UV770, antioxidant 1010, zinc stearate SAK-ZS-PLB are weighed according to the proportion.

[0028] b. Stirring: Put the carrier and additives into the high mixer and stir in turn. The amount of the mixed material should not exceed 2 / 3 of the volume, the speed is 10-20Hz, and the mixing time is 15 minutes.

[0029] c. Pelletizing: put the compounded mixture into the extruder, and cut the pellets through the pelletizer after the material is discharged from the die.

[0030] d. Screening: The cut particles are passed through a vibrating sieve, and the masterbatch with uniform size is screened out for packaging.

Embodiment 3

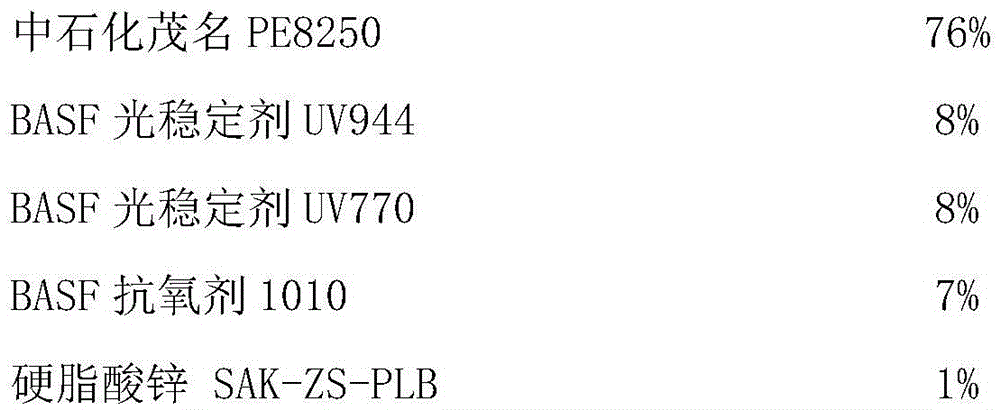

[0032] A masterbatch for plastic film products, its composition and corresponding weight percentage are as follows:

[0033]

[0034] The described manufacture method of the masterbatch that is used for plastic film product, comprises the following steps:

[0035] a. Weighing: Carrier powder PE8250, light stabilizer UV944, light stabilizer UV770, antioxidant 1010, zinc stearate SAK-ZS-PLB are weighed according to the proportion.

[0036] b. Stirring: Put the carrier and additives into the high mixer and stir in turn. The amount of the mixed material should not exceed 2 / 3 of the volume, the speed is 10-20Hz, and the mixing time is 15 minutes.

[0037] c. Pelletizing: put the compounded mixture into the extruder, and cut the pellets through the pelletizer after the material is discharged from the die.

[0038] d. Screening: The cut particles are passed through a vibrating sieve, and the masterbatch with uniform size is screened out for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com