A purification process system for coke oven gas

A purification process, a technology for coke oven gas, which is used in combustible gas purification, combustible gas purification/transformation, and removal of gas pollutants, etc. It can solve gas corrosion of gas pipelines and gas-related equipment, reduce steel quality, and reduce CO content. and other problems, to achieve the effect of facilitating system maintenance, avoiding secondary pollution, and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

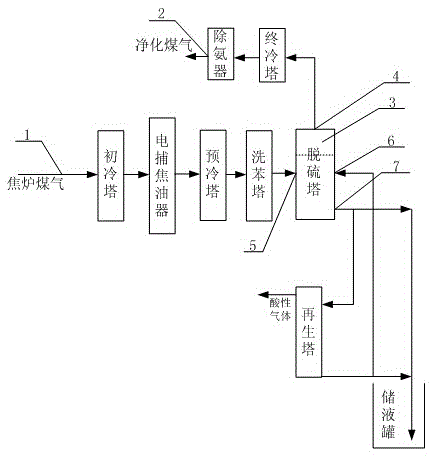

[0025] This embodiment proposes the purification process system of coke oven gas, and its structure is as follows figure 1 As shown, it includes an initial cooling tower, an electric tar catcher, a precooling tower, a benzene washing tower, a desulfurization tower, a final cooling tower and an ammonia remover connected in sequence, and the initial cooling tower is connected to the coke oven gas pipe 1. There is a purified gas outlet 2 on the desulfurization tower, and a regeneration tower is connected to the desulfurization tower to provide desulfurization liquid for the desulfurization tower. The upper part of the desulfurization tower is provided with a NaOH washing section 3, and the top of the desulfurization tower is provided with a gas outlet 4 connected with the final cooling tower. , the lower section of the desulfurization tower is provided with a gas inlet 5 connected to the benzene washing tower, a desulfurization liquid inlet 6 and a rich liquid outlet 7 connected t...

Embodiment 2

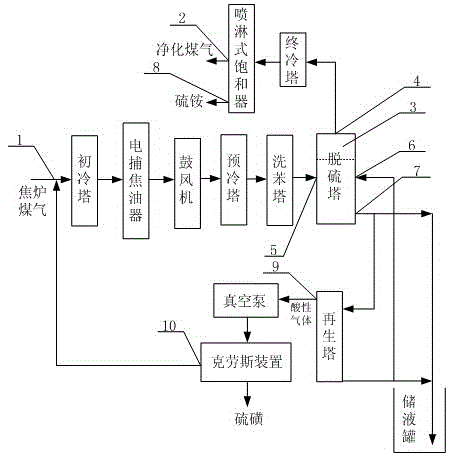

[0029] On the basis of Embodiment 1, this embodiment has the following differences: as figure 2 Shown, the ammonia remover that present embodiment relates to is the spray type saturator that is provided with ammonium sulfate outlet 8, in actual industrial process, spray type saturator comes from the ammonium sulfate production section, and coal gas is sent into the ammonium sulfate workshop section Spray-type saturator, in the spray-type saturator, it is sprayed with the circulating mother liquor containing 3.5-45% of free acid (sulfuric acid), and the circulating mother liquor absorbs the ammonia in the gas to form ammonium sulfate, and the ammonia is removed by the spray-type saturator The ammonia content in the final gas is generally less than 0.05g / m 3 .

[0030] Such as figure 2 As shown, in this embodiment, a blower is connected between the electric tar catcher and the pre-cooling tower, and the gas after tar removal is sent to the pre-cooling tower by the blower for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com