Hard steel cardboard and its preparation method

A technology of cardboard and hard steel, which is applied in the field of hard steel cardboard and its preparation, can solve the problems of insufficient electrical strength and volume resistance hardness, and achieve good infrared reflectivity, good water absorption, and improved volume resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

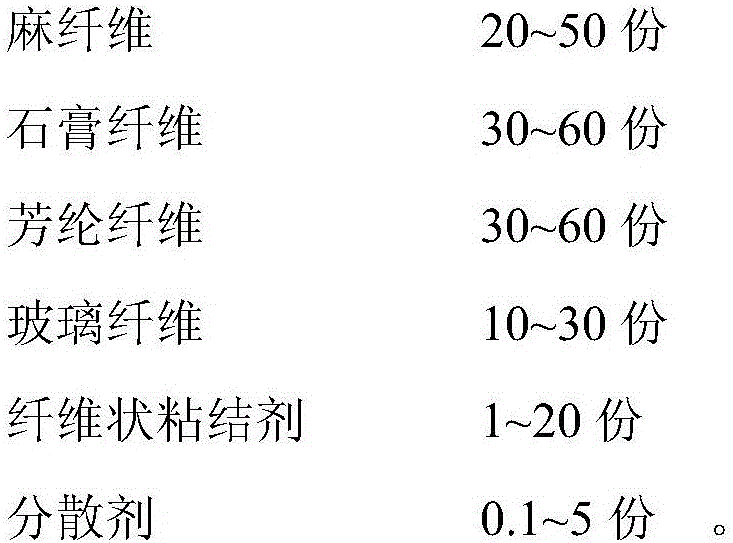

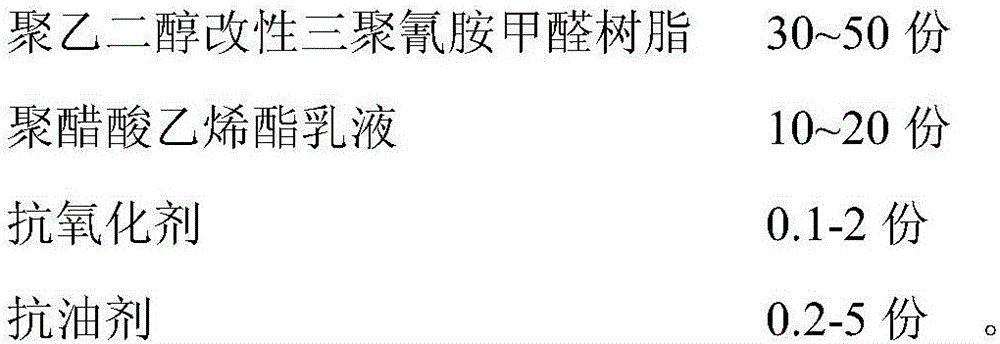

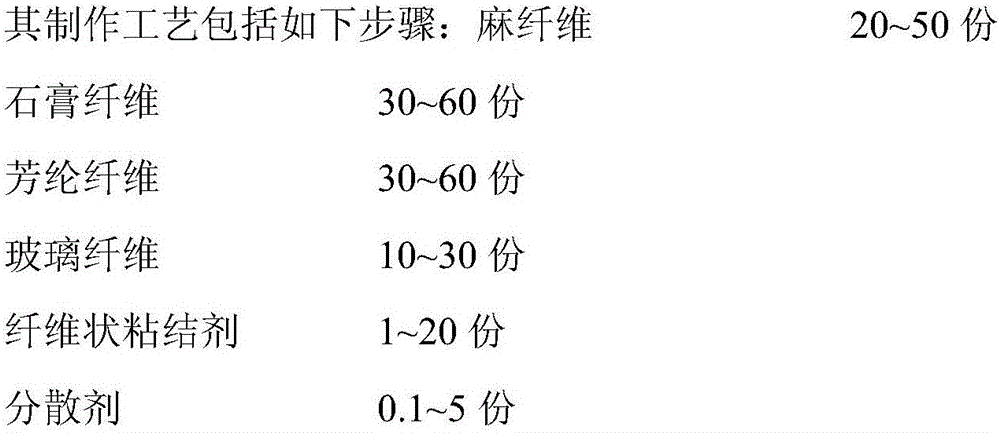

[0028] Hard steel cardboard, including base paper and impregnating agent, said base paper includes hemp fiber, gypsum fiber, aramid fiber, glass fiber, fibrous binder, dispersant, and said impregnating agent includes polyethylene glycol Modified melamine formaldehyde resin, polyvinyl acetate emulsion, antioxidant, anti-oil agent;

[0029] The glass fiber is nano glass fiber, and the particle size of the fiber is controlled below 100nm.

[0030] The anti-oil agent is fluorine-containing silane; the antioxidant is butyl hydroxyanisole (BHA); the fibrous binder is water-soluble PVA fiber; the dispersant is anionic polyacrylamide .

[0031] A kind of preparation method of hard steel cardboard as described above, comprises the steps:

[0032] (1) Beating and rinsing: 20kg of hemp fiber is beaten, the beating degree is 35-38°SR, and the wet weight is 7-8g, then the slurry obtained by beating is screened, purified and rinsed, and then 30kg of gypsum fiber, 30kg aramid fiber, 15kg ...

Embodiment 2

[0039] Hard steel cardboard, including base paper and impregnating agent, said base paper includes hemp fiber, gypsum fiber, aramid fiber, glass fiber, fibrous binder, dispersant, and said impregnating agent includes polyethylene glycol Modified melamine formaldehyde resin, polyvinyl acetate emulsion, antioxidant, anti-oil agent;

[0040] The glass fiber is nano glass fiber, and the particle size of the fiber is controlled below 100nm.

[0041] The anti-oil agent is polyperfluoroalkyl acrylate polymer; the antioxidant is butylated hydroxytoluene (BHT); the fibrous binder is Weirong fiber; the dispersion The agent is anionic polyoxyethylene.

[0042] A kind of preparation method of hard steel cardboard as described above, comprises the steps:

[0043] (1) Beating and rinsing: 30kg of hemp fiber is beaten, the beating degree is 35-38°SR, and the wet weight is 7-8g, then the slurry obtained by beating is screened, purified and rinsed, and then 40kg of gypsum fiber, 50kg aramid...

Embodiment 3

[0050] Hard steel cardboard, including base paper and impregnating agent, said base paper includes hemp fiber, gypsum fiber, aramid fiber, glass fiber, fibrous binder, dispersant, and said impregnating agent includes polyethylene glycol Modified melamine formaldehyde resin, polyvinyl acetate emulsion, antioxidant, anti-oil agent; the glass fiber is nano glass fiber, and the fiber particle size is controlled below 100nm.

[0051] The anti-oil agent is a polyperfluoroalkyl acrylate polymer; the antioxidant is tert-butylhydroquinone (TBHQ); the fibrous binder is a low melting point polyester; the The above-mentioned dispersant is anionic polyoxyethylene.

[0052] A kind of preparation method of hard steel cardboard as described above, comprises the steps:

[0053]

[0054] (1) Beating and rinsing: 50kg of hemp fiber is beaten, the beating degree is 35-38°SR, and the wet weight is 7-8g, then the slurry obtained by beating is screened, purified and rinsed, and then 60kg of gyps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com