Lithium titanate electrode material and preparation method thereof

An electrode material, lithium titanate technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of environmental pollution, electrode battery capacity, unsatisfactory discharge rate, graphene is difficult to disperse uniformly, etc., to achieve electrical conductivity Excellent, beneficial to industrial applications, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

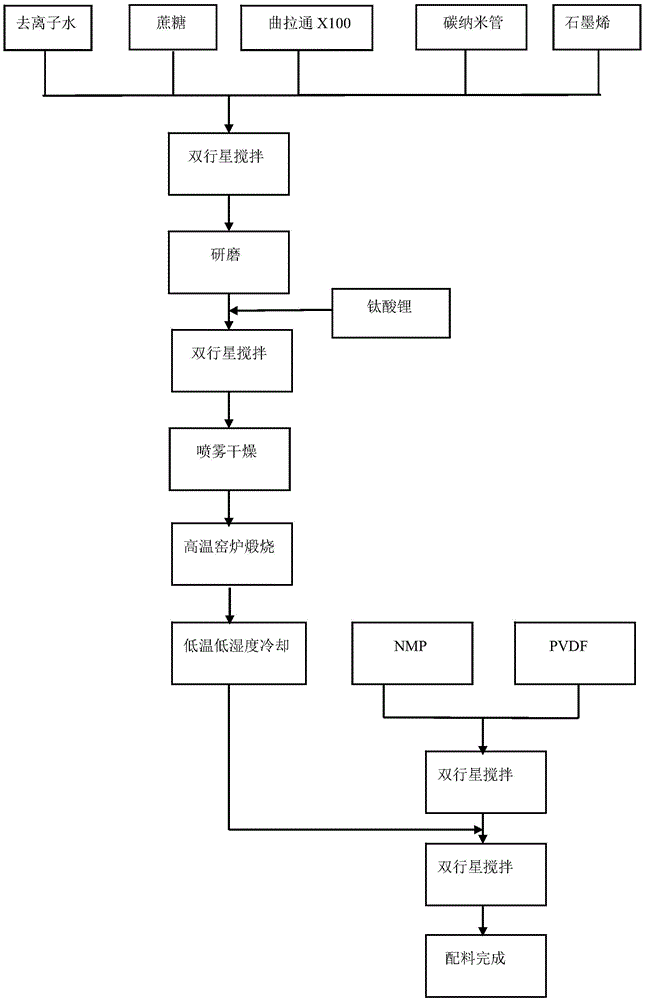

[0038] The preparation method of a kind of lithium titanate electrode slurry of this embodiment, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0039] (1) Preparation of lithium titanate electrode material

[0040] (1) add graphene, carbon nanotube to stir after deionized water, sucrose, triton X-100 are mixed, control the mass concentration of graphene in deionized water to be 2%, the mass concentration of carbon nanotube to be 3%, The mass concentration of sucrose is 5%, the mass concentration of Triton X-100 is 3%, using a double planetary mixer, the revolution linear velocity is 15m / s, the rotation linear velocity is 20m / s, and stirred for 60min to obtain slurry A;

[0041] (2) Put the slurry A into a grinder and add zirconia with a diameter of 0.5 to 1mm for grinding at a speed of 200r / min, grind for 150min, then add lithium titanate to the grinded slurry A to control the grinded The weight ratio of slurry A to li...

Embodiment 2

[0047] In this embodiment, a preparation method of a lithium titanate electrode slurry comprises the following steps:

[0048] (1) Preparation of lithium titanate electrode material

[0049] (1) add graphene, carbon nanotube to stir after deionized water, sucrose, triton X-100 are mixed, control the mass concentration of graphene in deionized water to be 3%, the mass concentration of carbon nanotube to be 1%, The mass concentration of Triton X-100 is 5%, using a double planetary mixer with a revolution linear velocity of 15m / s and an autorotation linear velocity of 15m / s, and stirring for 30min to obtain slurry A;

[0050] (2) Put the slurry A into a grinder and add zirconia with a diameter of 0.5 to 1mm for grinding at a speed of 250r / min, grind for 60min, then add lithium titanate to the grinded slurry A to control the grinded The weight ratio of slurry A to lithium titanate is 6:4, using a double planetary mixer, stirring at a revolution linear velocity of 15m / s and a rota...

Embodiment 3

[0056] In this embodiment, a preparation method of a lithium titanate electrode slurry comprises the following steps:

[0057] (1) Preparation of lithium titanate electrode material

[0058] (1) add graphene, carbon nanotube to stir after deionized water, sucrose, Triton X-100 are mixed, control the mass concentration of graphene in deionized water to be 3%, the mass concentration of carbon nanotube to be 2%, The mass concentration of sucrose is 3%, and the mass concentration of Triton X-100 is 4%, using a double planetary mixer with a revolution linear velocity of 5 m / s and an autorotation linear velocity of 25 m / s, and stirring for 60 minutes to obtain slurry A;

[0059] (2) Put the slurry A into a grinder and add zirconia with a diameter of 0.5 to 1mm for grinding at a speed of 150r / min, grind for 300min, then add lithium titanate to the grinded slurry A to control the grinded The weight ratio of slurry A to lithium titanate is 6:4, using a double planetary mixer with a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com