Preparation method of anode material, namely nitrogen-doped SnS/C composite nanomaterial for lithium battery

A negative electrode material, lithium battery technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of difficult to control the volume expansion of SnS negative material, to avoid the capacity decay too fast, inhibit the The effect of volume expansion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

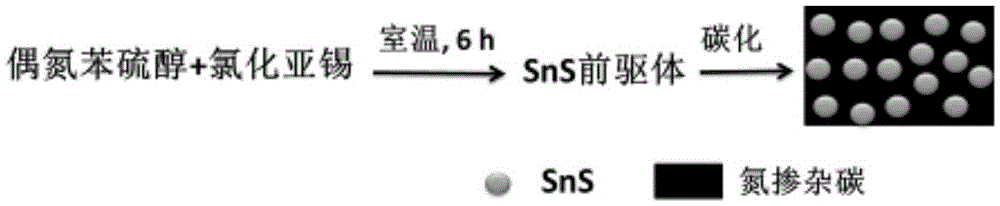

[0030] according to figure 1 The process shown in the preparation of nitrogen-doped SnS / C composite nanomaterials, 20mmol of 4-octyloxy-4'-(10-mercaptodecyloxy) azobenzene and 20mmol of triethylammonium were added to 60ml of toluene, stirred for 20min to make After uniform dispersion, add 10mmol SnCl 2 , Reaction at room temperature for 6h. After the reaction was completed, cool to room temperature, filter to obtain a crude product, wash the crude product with ethanol several times, and vacuum-dry the obtained sample at 80° C. for 6 hours to obtain a yellow SnS precursor. 0.5 g of the aforementioned SnS precursor was accurately weighed, and then calcined at 700° C. for 4 h in a nitrogen atmosphere to finally obtain a black nitrogen-doped SnS / C composite nanomaterial.

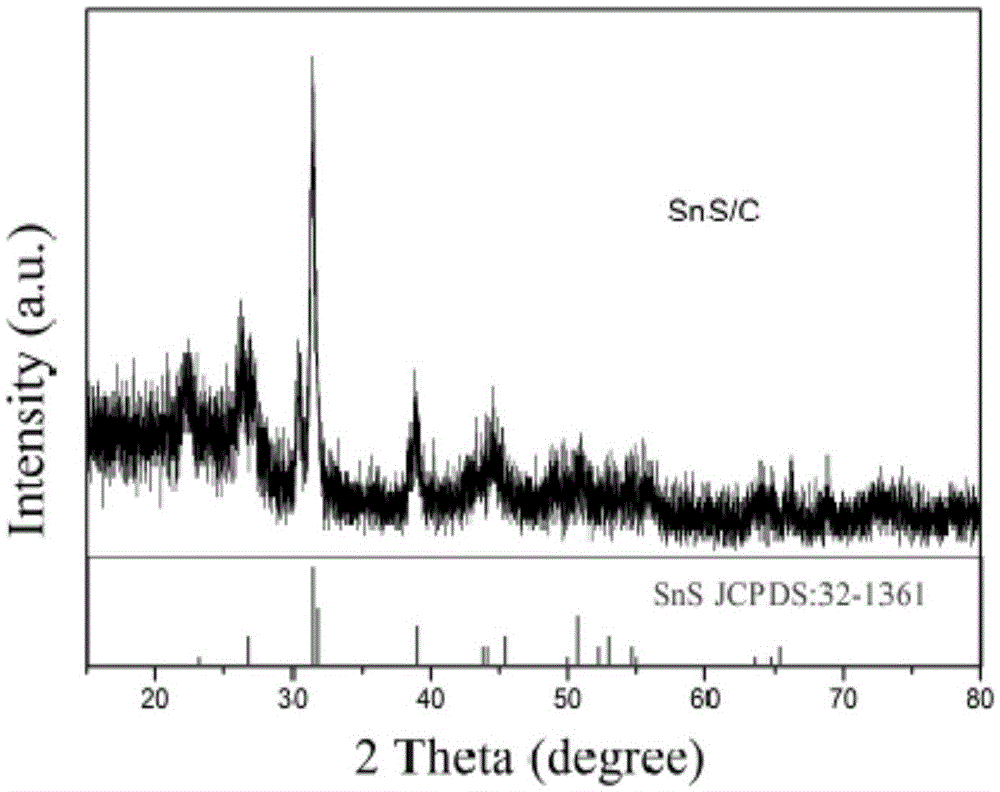

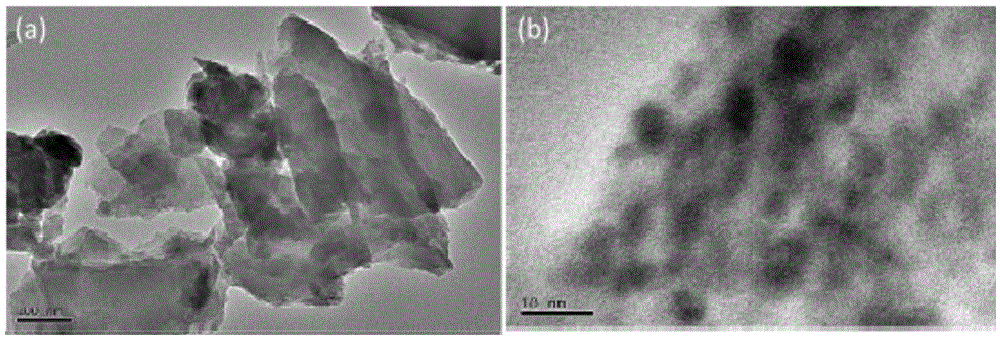

[0031] The prepared nitrogen-doped SnS / C composite nanomaterials were characterized by X-ray diffraction analysis, the results are as follows figure 2 shown. Characterized by transmission electron microscop...

Embodiment 2

[0033] Add 20mmol of 4-octyloxy-4'-(10-mercaptodecyloxy)azobenzene and 22mmol of triethylammonium into 60ml of toluene, stir for 20min to disperse evenly, then add 11mmol of SnCl 2 , Reaction at room temperature for 6h. After the reaction was completed, cool to room temperature, filter to obtain a crude product, wash the crude product with ethanol several times, and vacuum-dry the obtained sample at 100° C. for 4 hours to obtain a yellow SnS precursor. 1 g of the SnS precursor was accurately weighed, and calcined at 600° C. for 8 h in a nitrogen atmosphere to finally obtain a black nitrogen-doped SnS / C composite material.

Embodiment 3

[0035] Add 20mmol of 4-octyloxy-4'-(10-mercaptodecyloxy)azobenzene and 24mmol of triethylammonium into 60ml of toluene, stir for 20min to disperse evenly, then add 12mmol of SnCl 2, Reaction at room temperature for 6h. After the reaction was completed, cool to room temperature, filter to obtain a crude product, wash the crude product with ethanol several times, and vacuum-dry the obtained sample at 100° C. for 6 hours to obtain a yellow SnS precursor. 0.6 g of the SnS precursor was accurately weighed, and then calcined at 800° C. for 4 h in a nitrogen atmosphere to finally obtain a black nitrogen-doped SnS / C composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com