Preparation method for all-solid-state polymer electrolyte membrane with three-layer structure

An all-solid polymer, electrolyte membrane technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems to be advanced, and achieve the effects of excellent mechanism and mechanical properties, simple process, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

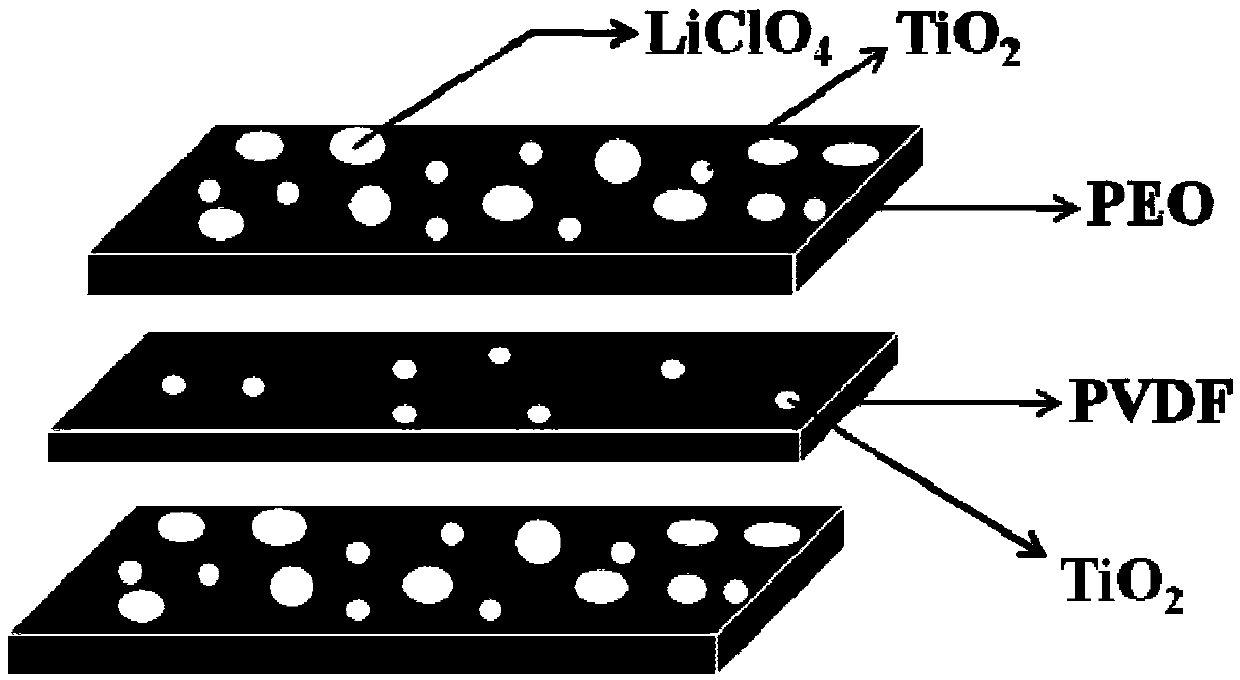

[0029] The present invention a kind of electrospinning preparation method of the all-solid-state polymer electrolyte membrane of the lithium ion battery of three-layer structure, comprises the following steps:

[0030] Step 1. Choose PEO and PVDF as substrates, and use LiClO as the lithium salt 4 , the nanoparticles are TiO 2 Nanoparticles;

[0031] Step two, PEO and LiClO 4 According to the amount of substance ratio is n EO :n LiClO4 =8:1 dissolved in acetonitrile solvent, magnetically stirred for 1h, then added TiO 2 Nanoparticles were dispersed by ultrasonic vibration for 1h, making TiO 2 The nanoparticles are uniformly dispersed, followed by magnetic stirring for 12 hours to obtain a uniformly dispersed emulsion;

[0032] Step three, dissolve PVDF in V DMAc :V 丙酮 =7:3 mixed solution, magnetically stirred for 1h, and then added TiO 2 Nanoparticles were dispersed by ultrasonic vibration for 1h, making TiO 2 The nanoparticles are uniformly dispersed, followed by mag...

Embodiment 1

[0037] (1) Two substrates, PEO and PVDF, are selected, and LiClO is selected as the lithium salt 4 , the nanoparticles are TiO 2 Nanoparticles (particle size 5-10nm).

[0038] (2) Combine PEO with LiClO 4 Dissolve in acetonitrile solvent according to a certain amount of substances, stir magnetically, and then add a certain amount of TiO2 Nanoparticles, ultrasonic dispersion, magnetic stirring, to obtain a well-dispersed emulsion.

[0039] (3) Dissolve a certain amount of PVDF in V DMAc :V 丙酮 =7:3 mixed solution, magnetic stirring, and then add a certain amount of TiO 2 Nanoparticles, ultrasonic dispersion, magnetic stirring, to obtain a well-dispersed emulsion.

[0040] (4) The spinning solutions prepared in (2) and (3) were prepared by electrospinning layer by layer. By adjusting the volumes of the two spinning solutions, the thickness ratio of the outer layer to the inner layer was controlled to be 5:1. Finally, the obtained three-layer polymer electrolyte membrane was...

Embodiment 2

[0048] (1) Two substrates, PEO and PVDF, are selected, and LiClO is selected as the lithium salt 4 , the nanoparticles are TiO 2 Nanoparticles (particle size 5-10nm).

[0049] (2) Combine PEO with LiClO 4 Dissolve in acetonitrile solvent according to a certain amount of substances, stir magnetically, and then add a certain amount of TiO 2 Nanoparticles, ultrasonic dispersion, magnetic stirring, to obtain a well-dispersed emulsion.

[0050] (3) Combine PVDF with LiClO 4 Soluble in V according to a certain ratio of substances DMAc :V 丙酮 =7:3 mixed solution, magnetic stirring, and then add a certain amount of TiO 2 Nanoparticles, ultrasonic dispersion, magnetic stirring, to obtain a well-dispersed emulsion.

[0051] (4) The spinning solutions prepared in (2) and (3) were prepared by electrospinning layer by layer. By adjusting the volumes of the two spinning solutions, the thickness ratio of the outer layer to the inner layer was controlled to be 3:1. Finally, the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com