High-conductivity transparent glass-based circuit board

A technology of transparent glass and glass substrate, which is applied in the direction of transparent dielectric, circuit substrate material, printed circuit, etc., and can solve the problems of loose connection between glass plate and conductive circuit, uneven surface of glass-based circuit board, easy damage and falling off of conductive circuit, etc. , to achieve the effect of maintaining superconductivity, dense molecular arrangement, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

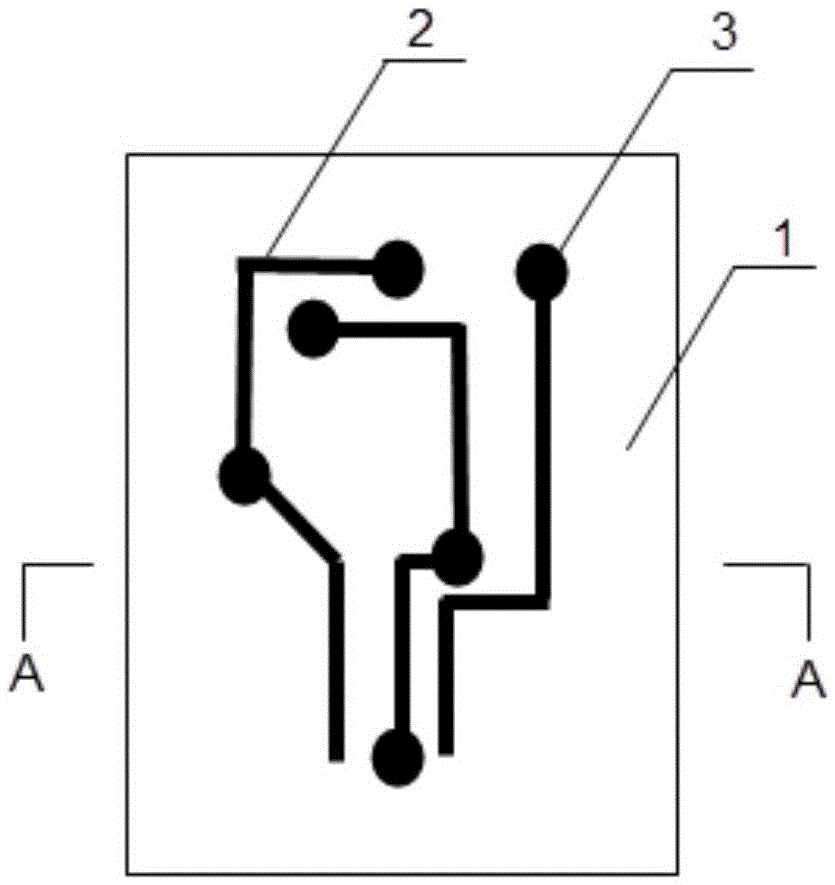

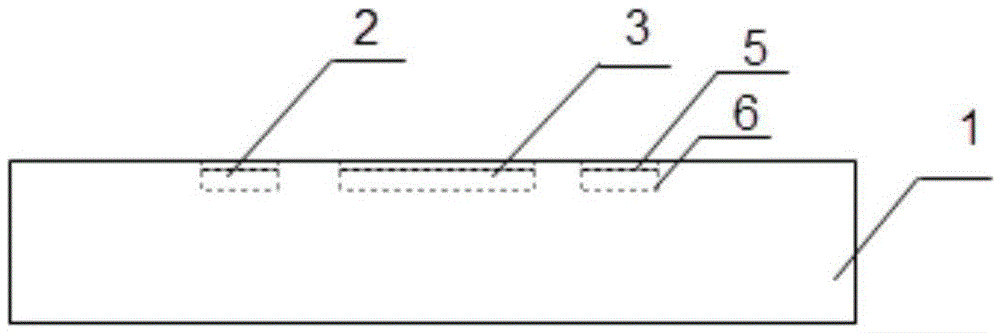

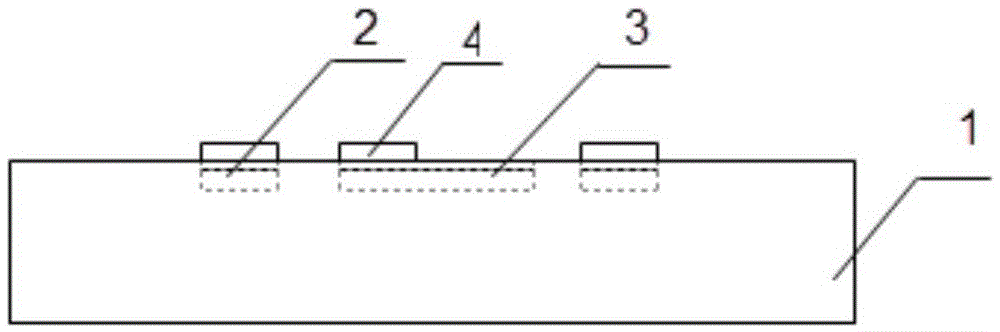

[0020] refer to figure 1 and figure 2 , the present invention provides a high-conductivity transparent glass-based circuit board, including a glass substrate 1, the surface of the glass substrate is provided with a conductive paste printed on the air surface of the glass substrate after baking, heating and cooling A conductive circuit 2 fused with the surface of the glass substrate, the conductive circuit 2 is a graphene layer, or a conductive layer composed of a graphene layer 5 on the surface and a metal layer 6 fused with the glass substrate at the bottom layer, and the graphene layer 5 The contact surfaces with the metal layer 6 are fused together, and the surface of the glass substrate 1 is flush with the upper surface of the conductive circuit 2 .

[0021] The conductive paste is composed of conductive powder, low-temperature glass powder, ethyl cellulose, terp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com