Intrauterine device made of degradable composite material with layered nano-structure

A technology of intrauterine contraceptives and composite materials, which is applied in the field of female contraceptive devices, can solve problems such as uncontrollable release of copper ions, dysmenorrhea in patients, complicated production, etc., achieves good contraceptive effect, eliminates severe pain, and has a simple production method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

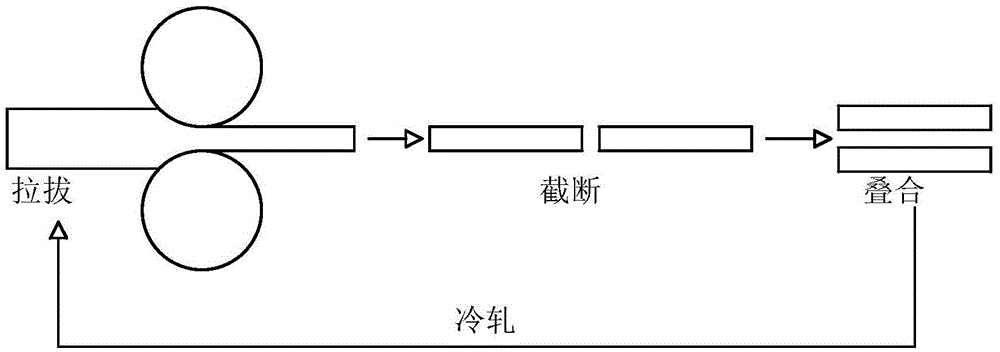

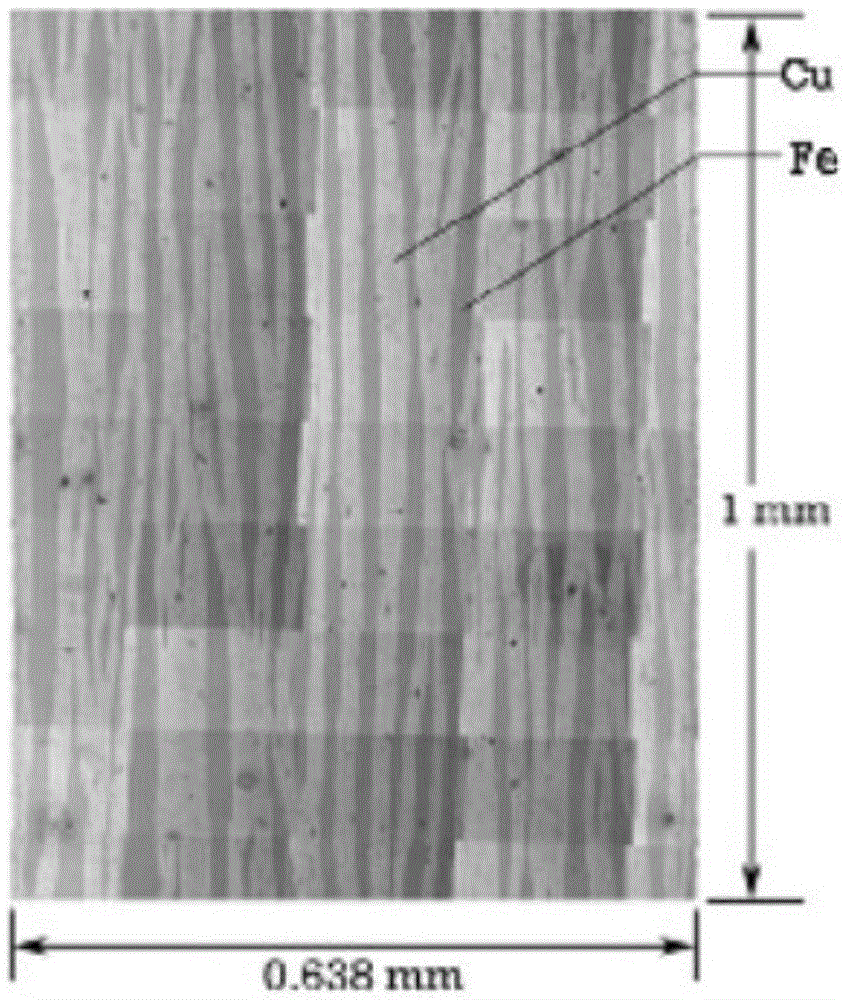

[0040] The preparation method of the degradable composite material of the layered nanostructure of the present embodiment comprises the following steps:

[0041] Step 1. Select a pure copper plate and a pure iron plate with a thickness of 4mm respectively;

[0042] Step 2. Clean the surface of the pure copper sheet and the pure iron sheet selected in step 1 by sandblasting and polishing;

[0043] Step 3, stacking the processed pure copper sheet and pure iron sheet together in step 2, and rolling at room temperature, the rolling deformation is 50% of the total thickness of the laminated sheet, to obtain a cold-rolled composite sheet;

[0044] Step 4. Put the cold-rolled composite sheet obtained in step 3 into a vacuum heat treatment furnace for annealing heat treatment. The annealing temperature is 800° C., and the annealing time is 3 hours to obtain an annealed rolled composite sheet;

[0045] Step 5, cut off the annealed rolled composite plate in step 4 from the middle, and ...

Embodiment 2

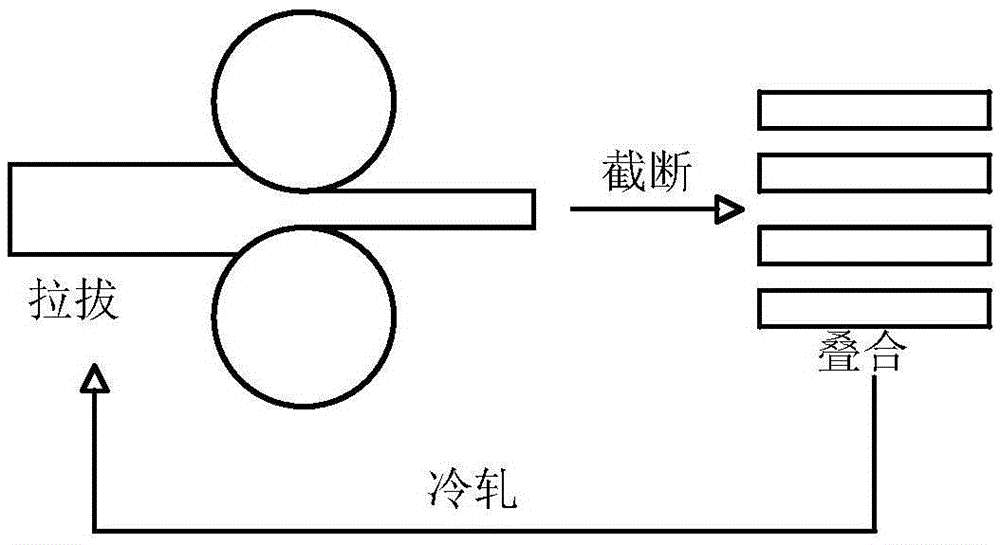

[0052] The preparation method of the degradable composite material of the layered nanostructure of the present embodiment comprises the following steps:

[0053] Step 1. Select 10 pure copper plates and 10 pure iron plates with a thickness of 0.5mm respectively;

[0054] Step 2, cleaning the surface of the pure copper sheet and the pure iron sheet selected in step 1 by pickling and polishing;

[0055] Step 3, stacking the plates processed in step 2 in a staggered combination of copper, iron, copper, and iron and rolling at room temperature, the rolling deformation is 50% of the total thickness of the stacked plates, and cold rolling is obtained. Composite panels;

[0056] Step 4. Put the cold-rolled composite sheet obtained in step 3 into a vacuum heat treatment furnace for annealing heat treatment. The annealing temperature is 800° C., and the annealing time is 3 hours to obtain an annealed rolled composite sheet;

[0057] Step 5, cut off the annealed rolled composite plate...

Embodiment 3

[0064] Such as Figure 4 As shown, the present embodiment relates to an intrauterine device with a degradable composite material having a layered nanostructure, and the IUD includes a plurality of composite material segments made of a degradable composite material having a layered nanostructure 11. Multiple composite material nodes 11 are connected in series on a non-biological suture 12, and a composite material knot 13 made of a degradable composite material with a layered nanostructure is provided at one end of the non-biological suture 12.

[0065] The IUD is composed of 6 composite material sections 11, each composite material section 11 is 5 mm long and about 2.2 mm in diameter, and is strung on a polypropylene non-biological suture 12, and then the polypropylene non-biological suture 12 The end is composed of a composite material knot 13 made of a degradable composite material with a layered nanostructure; when placed, the composite material knot 13 is fixed at 1 cm of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com