Technological water discharge and recycling device for tap water plant

A technology for process drainage and tap water, applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problem of increasing operating energy consumption, unstable water quality, and difficult bacteriological index. It can achieve the effect of high degree of automation control, excellent and stable effluent quality, and good promotion and application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

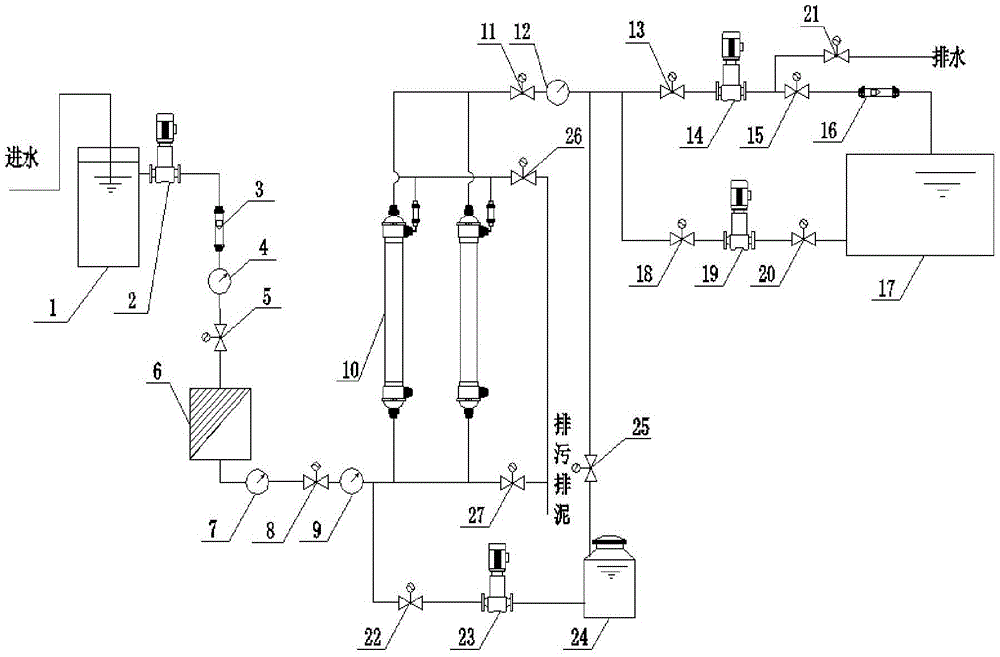

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] figure 1 It is a device diagram of the present invention, as shown in the figure, the equipment for waterworks process drainage recovery of the present invention includes a microfiltration system, an ultrafiltration system and an automatic cleaning system; wherein said microfiltration system includes a raw water tank 1, The first electromagnetic valve 5, the microfiltration assembly 6 and the second electromagnetic valve 8; the ultrafiltration system includes an ultrafiltration assembly 10, a third electromagnetic valve 11, a fourth electromagnetic valve 13, a produced water pump 14, and a fifth electromagnetic valve 15 And clear water tank 17; Described automatic cleaning system includes backwash water pump 19. The microfiltration system, wherein the water outlet of the raw water tank 1 is connected to the water inlet of the raw water pump 2, the raw water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com