Formula and preparation method of composite fungus straw bio-adsorbent

A biosorbent and straw technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of limiting cellulose adsorption, low straw adsorption performance, and hindering cellulose contact, etc., to achieve Avoid harsh culture conditions, low price, and improve the effect of adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The invention discloses a formula and a preparation method of a fungal straw composite biosorbent, and the specific method is as follows:

[0018] Material preparation: crush the dry straw with a universal grinder and pass through a 60-mesh sieve for later use;

[0019] Preparation of culture medium: Weigh 1 part of straw, 1 part of water, 0.05 part of nitrogen source, and 0.5 part of pH adjuster to blend, and spread it on a petri dish with a thickness of 0.5-1 cm. Dilute 3×10 6 cuf Aspergillus niger spores were inoculated on the surface of the solid medium;

[0020] Fermentation conditions: ferment and cultivate at 30°C for 3-7 days, dry at 50°C for 3-5 hours, and become a composite biosorbent for the symbiosis of straw and fungi.

Embodiment 2

[0022] The invention discloses a formula and a preparation method of a fungal straw composite biosorbent, and the specific method is as follows:

[0023] Material preparation: crush the dry straw with a universal grinder and pass through a 60-mesh sieve for later use;

[0024] Production medium: Weigh 1 part of straw, 3 parts of water, 0.1 part of nitrogen source, and 0.8 part of pH regulator to blend, and spread it on a petri dish with a thickness of 0.5-1cm, and mix 8×10 6 cuf Aspergillus niger spores were inoculated on the surface of the solid medium;

[0025] Fermentation conditions: ferment and cultivate at 30°C for 3-7 days, dry at 50°C for 3-5 hours, and become a composite biosorbent for the symbiosis of straw and fungi.

Embodiment 3

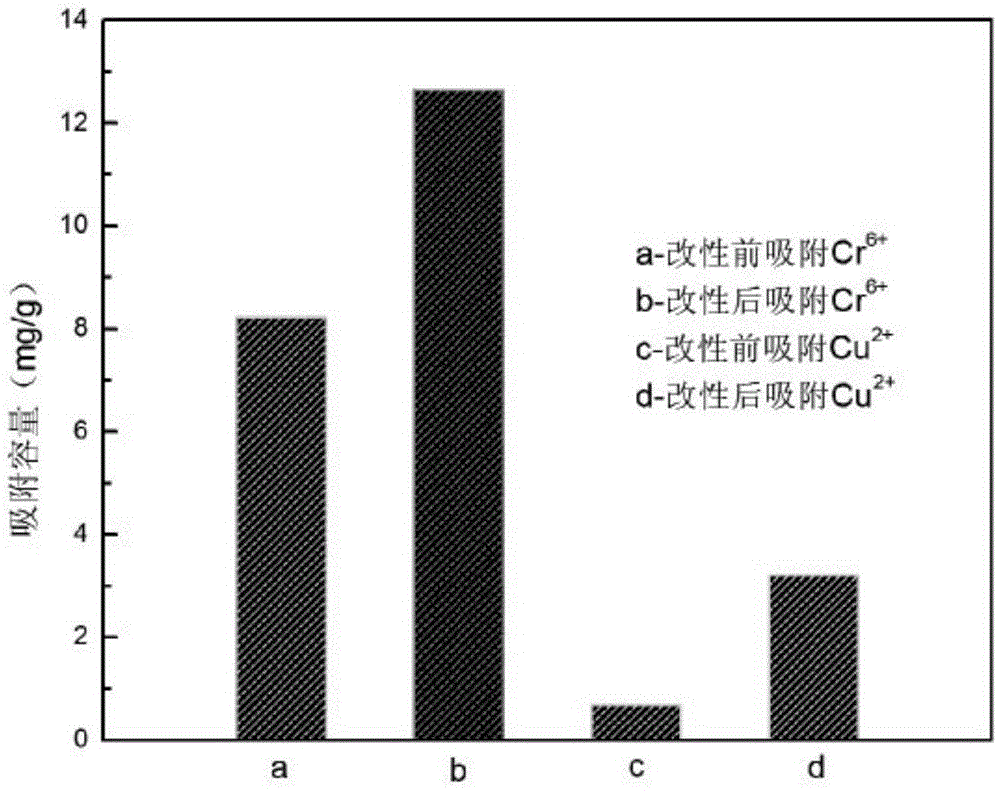

[0027] Experimental purpose and method: In order to verify the adsorption effect of fungal straw composite biosorbent on heavy metal-containing wastewater, this experiment uses fungal straw composite biosorbent to treat heavy metal wastewater containing chromium and copper, and 0.1g of agricultural waste and fungus-modified agricultural The waste composite biosorbent was added to 20mL of 100mg / L chromium solution and copper solution respectively at a temperature of 30°C and a rotation speed of 100rmp. After two hours of adsorption, the amount of metal ion adsorption was detected.

[0028] Experimental results: if figure 1 As shown, the adsorption capacity of the four groups a-d were 8.22mg / g and 12.64mg / g, 0.68mg / g and 3.2mg / g respectively, indicating that the adsorption capacity of agricultural wastes has been improved after biological modification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com