Novel normal-temperature arsenic removal agent and preparation method and application thereof

A technology for removing arsenic and surfactants, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, catalysts for physical/chemical processes, etc. and other problems, to achieve the effects of excellent catalytic performance, high arsenic capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

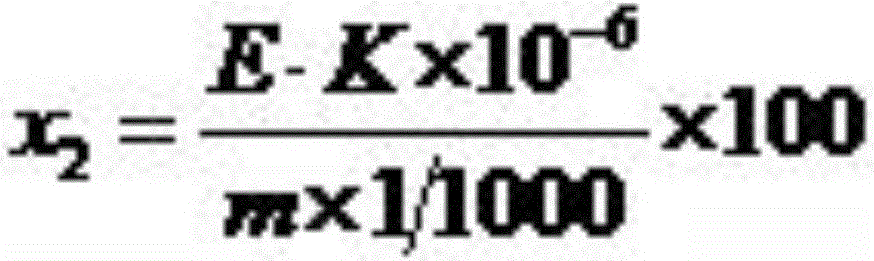

Image

Examples

Embodiment 1

[0050] Embodiment 1, preparation novel normal temperature arsenic removal agent:

[0051] A preparation method of a novel normal temperature arsenic removal agent, comprising the steps of:

[0052] 1) Pretreatment of the carrier: Under the environment of nitrogen protection, 100g of titanium-aluminum carrier (wherein the mass fraction of titanium oxide is 30%) is treated under the following conditions: firstly, the heating rate is 2°C / min from 70°C to Raise the temperature to 400°C, and keep it at a constant temperature of 400°C for 40 minutes; then raise the temperature to 550°C at a heating rate of 3°C / min, and roast at 550°C for 3 hours, and cool to room temperature to obtain a pretreated carrier; after detection by an automatic adsorption instrument, It is known that the specific surface area of the pretreatment carrier is 350m 2 / g, the pore size is 5nm;

[0053] 2) Immerse the pretreated carrier in step 1) in an aqueous solution of nickel nitrate with a molar concent...

Embodiment 2

[0057] Embodiment 2, preparation novel normal temperature arsenic removal agent:

[0058] A preparation method of a novel normal temperature arsenic removal agent, comprising the steps of:

[0059] 1) Pretreatment of the carrier: under the environment of nitrogen protection, the specific surface area of 1g is 300m 2 / g, pore diameter of 5nm titanium aluminum carrier (wherein the mass fraction of titanium oxide is 40%) is processed under the following conditions: first, the temperature is raised to 400°C with a heating rate of 2°C / min, and kept at a constant temperature of 400°C 40min; then heated up to 550°C at a heating rate of 5°C / min, and roasted at 550°C for 3h, cooled to room temperature to obtain a pretreated carrier; through an automatic adsorption instrument, it was known that the specific surface area of the pretreated carrier was 300m 2 / g, the pore size is 6nm;

[0060] 2) Immerse the carrier pretreated in step 1) in an aqueous solution of nickel nitrate with ...

Embodiment 3

[0064] Embodiment 3, preparation novel normal temperature arsenic removal agent:

[0065] A preparation method of a novel normal temperature arsenic removal agent, comprising the steps of:

[0066] 1) The specific surface area of 50g is 500m 2 / g, the alumina carrier with a pore diameter of 4nm is impregnated in the aqueous solution of nickel nitrate with a molar concentration of 1mol / L. 60°C for 1 hour; after filtering, dry the retentate at 120°C for 12 hours, and finally bake it in a muffle furnace at 450°C for 3 hours to obtain a NiO-loaded carrier, so that the NiO loading amount accounts for the alumina carrier 0.5% of mass;

[0067] 2) Immerse the NiO-loaded carrier in step 1) in an aqueous solution of copper nitrate with a molar concentration of 4mol / L, and add surfactant PEG2000 accounting for 0.1% of the mass of copper nitrate to the aqueous solution of copper nitrate until completely dissolved, The impregnation conditions are as follows: use ultrasonic impregnati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com