High-precision micro-fine metal sphere forming machine

A high-precision molding machine technology, applied in the field of electronic product packaging materials, can solve the problems of low output, large ball diameter error, complex process, etc., and achieve the effect of uniform composition content, small diameter error, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

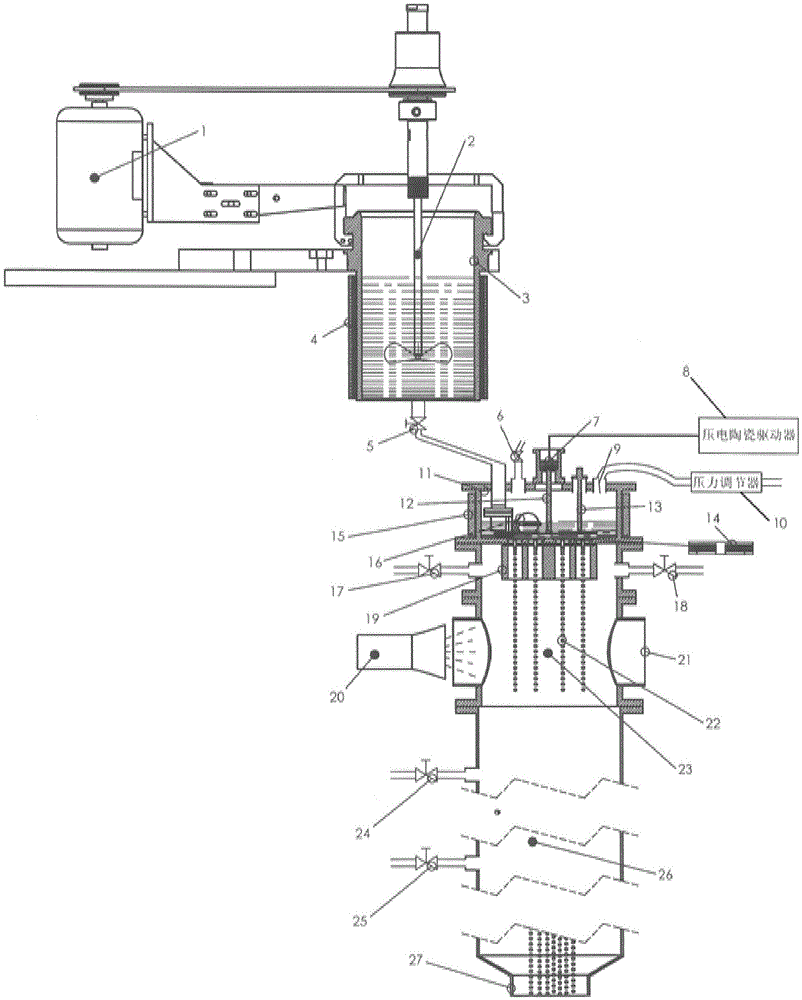

[0026] In order to make the above objects, features and advantages of the present invention more clearly understood, the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0027] see figure 1 , a high-precision fine metal sphere forming machine, including a melting kettle 3, a discharge valve 5, and a ball shooting kettle 11, and the melting kettle 3 is connected to the ball shooting kettle 11 through the discharge valve 5; The shooting kettle 11 includes a first liquid nitrogen valve 24, a second liquid nitrogen valve 25, a high-voltage electrostatic head 19, a piezoelectric ceramic driver 8, a piezoelectric ceramic sheet 7, an injection rod 12, a microporous diamond sheet 14, and a spherical shape. area 23, sphere forming area 26, sphere outlet 27, the piezoelectric ceramic sheet 7 is connected to the piezoelectric ceramic driver 8 and the injection rod 12 respectively, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com