Fertilizer for increasing content of lycopene in tomatoes as well as preparation method and application of fertilizer

A tomato and fertilizer technology, applied in the field of fertilizer and its preparation for increasing the content of lycopene in tomato, can solve the problem of affecting the interaction of microorganisms, micro-animals and plant roots, affecting the full conversion and accumulation of nutrients, and destroying soil micro-ecology Environmental and other issues, to achieve the effect of being suitable for large-scale production and utilization, realizing waste utilization, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The application also provides the preparation method of above-mentioned tomato bio-fertilizer, comprising the following steps:

[0028] The roots, stems and leaves of tomato and the roots, stems and leaves of leguminous plants are crushed separately, mixed with animal feces, and part of EM bacteria agent is added to ferment and cultivate to obtain product I; corn stalks are puffed, and the processed puffed product is mixed with vitamins and glucose, and the remaining part of EM bacteria is added The product was fermented and cultivated to obtain product II; the product I and product II were mixed with biochar and granulated.

[0029] In the present invention, the roots, stems and leaves of tomato and the roots, stems and leaves of leguminous plants are respectively pulverized, and then passed through a 30-50 mesh sieve, preferably a 40 mesh sieve. The present invention does not limit the specific crushing methods of tomato roots, stems and leaves and leguminous plant ro...

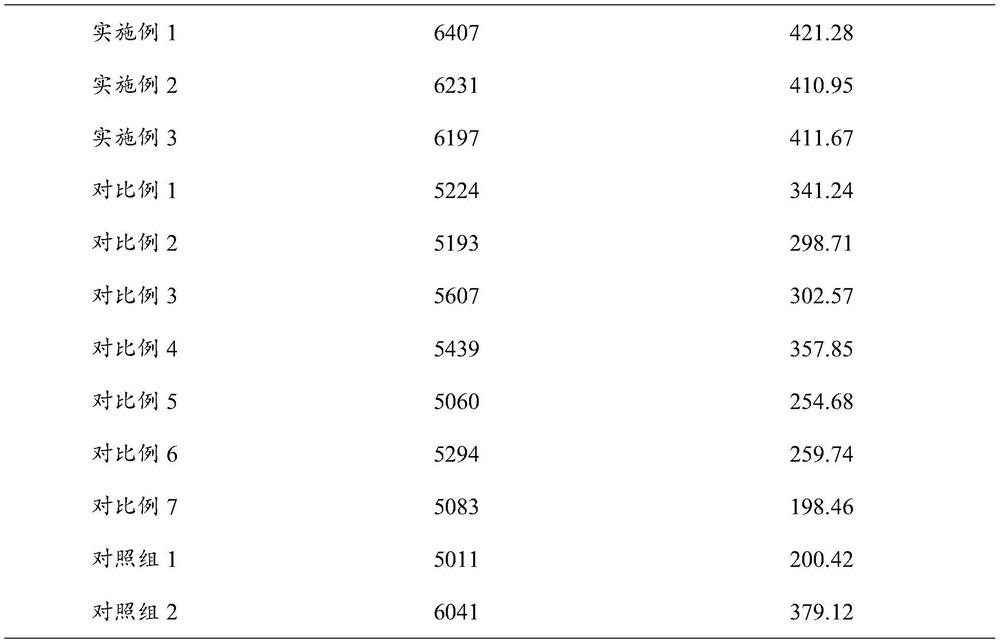

Embodiment 1

[0040] A tomato bio-fertilizer, comprising: 60kg of tomato roots, stems and leaves, 50kg of leguminous plant roots, stems and leaves, 25kg of corn stalks, 45kg of animal manure, 60kg of biochar, 3kg of vitamins, 3kg of glucose, and 0.5kg of EM bacterial agent. Vitamins are composed of vitamin B, vitamin C, vitamin E, and vitamin D in a mass ratio of 1:6:3:1.

[0041] Crush the tomato rhizome leaves and leguminous plant rhizome leaves respectively, pass through a 40-mesh sieve, mix the tomato root stem leaves and leguminous plant root stem leaves evenly after sieving, then mix with animal manure, spray 0.3kg EM bacterial agent, spray while spraying Stir evenly, ferment at 40°C for 12 days to obtain product I; use screw extrusion to send corn stalks into the puffing machine for puffing treatment, then add vitamins and glucose in turn to the puffed material obtained from the treatment, mix well, and spray 0.2 kg EM bacterial agent, sprayed and stirred evenly, fermented at 33°C fo...

Embodiment 2

[0043] A tomato bio-fertilizer, comprising: 70kg of tomato roots, stems and leaves, 46kg of leguminous plant roots, stems and leaves, 28kg of corn stalks, 44kg of animal manure, 60kg of biochar, 3kg of vitamins, 2.5kg of glucose, and 1kg of EM bacterial agent. Vitamins are composed of vitamin B, vitamin C, vitamin E, and vitamin D in a mass ratio of 1.5:6:3.5:1.5.

[0044] Crush the tomato rhizome leaves and leguminous plant rhizome leaves respectively, pass through a 30-mesh sieve, mix the tomato root stem leaves and leguminous plant rhizome leaves evenly after sieving, then mix with animal manure, spray 0.5kg EM bacterial agent, spray while spraying Stir evenly, ferment at 41°C for 11 days to obtain product I; use screw extrusion to send corn stalks into an extruder for puffing treatment, then add vitamins and glucose to the processed puffed material in turn, mix well, and spray 0.5 kg EM bacterial agent, sprayed and stirred evenly, fermented at 32°C for 3 days to obtain pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com