Solid formulation for dialysis and process for producing the same

A solid preparation and particle technology, applied in the field of 3-dosage dialysis solid preparations and dialysis solid preparations, to achieve the effects of easy handling, stable long-term storage, inhibition of coagulation and consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

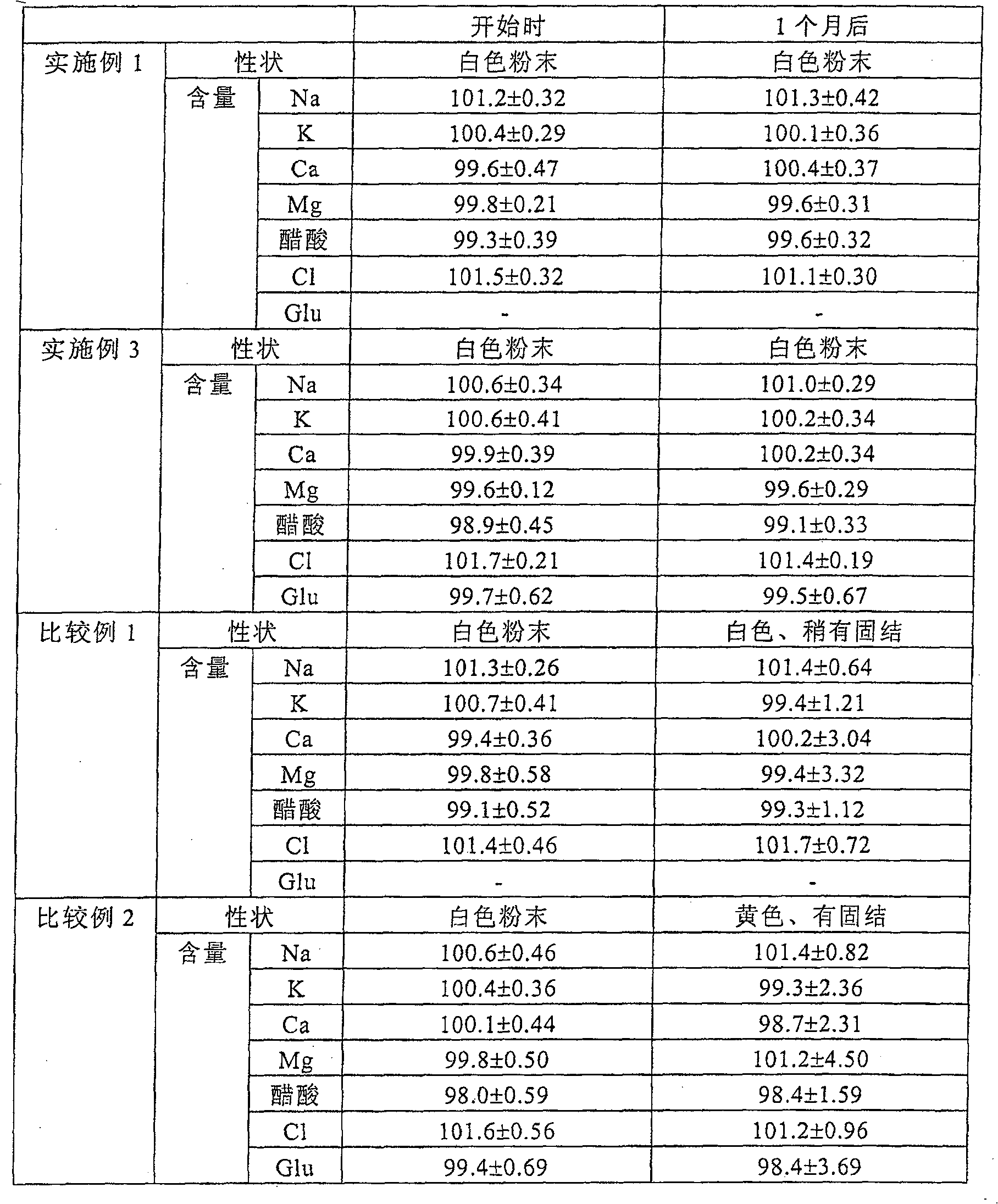

Embodiment 1

[0070] 32.0 parts by weight of magnesium chloride and 103.35 parts by weight of anhydrous sodium acetate are uniformly dissolved in 323.2 parts by weight of purified water to prepare an aqueous solution. 984.9 parts by weight of sodium chloride with an average particle size of 300 μm flowing in a rotating fluidized bed granulator (MP-01, manufactured by Pak Rec Co., Ltd.), under the conditions of an intake air temperature of 80°C and a rotor speed of 300 rpm , Spraying with the above-mentioned aqueous solution and drying it to produce granular granules of first particles with an average particle diameter of 500 μm.

[0071]Then, 47.0 parts by weight of potassium chloride, 69.5 parts by weight of calcium chloride, and 103.35 parts by weight of anhydrous sodium acetate were uniformly dissolved in 525.4 parts by weight of purified water to prepare an aqueous solution. 984.9 parts by weight of sodium chloride with an average particle diameter of 300 μm flowing in a fluidized bed granu...

Embodiment 2

[0074] 47.0 parts by weight of potassium chloride, 32.0 parts by weight of magnesium chloride, and 103.35 parts by weight of anhydrous sodium acetate were uniformly dissolved in 435.8 parts by weight of purified water to prepare an aqueous solution. 984.9 parts by weight of sodium chloride with an average particle diameter of 300 μm flowing in a fluidized bed granulator (MP-01, manufactured by Pak Rec Co., Ltd.) at an intake temperature of 80°C, a rotor speed of 300 rpm, and an exhaust temperature Under the conditions of 40 to 50°C, the above-mentioned aqueous solution is sprayed and dried to produce granular granules of first particles having an average particle diameter of 500 μm. Then, 69.5 parts by weight of potassium chloride and 103.35 parts by weight of anhydrous sodium acetate were uniformly dissolved in 413 parts by weight of purified water to prepare an aqueous solution. 984.9 parts by weight of sodium chloride with an average particle size of 300 μm flowing in a fluidiz...

Embodiment 3

[0076] In the same manner as in Example 1, first and second particles (the average particle size of either one was about 500 μm) were obtained.

[0077] Separately from this, 1000 parts by weight of 25w / w% glucose aqueous solution were prepared. 1000 parts by weight of glucose powder with an average particle diameter of 180μm was put into a rotating fluidized bed granulator (MP-01, manufactured by Poretec), the counter-flowing glucose particles were at an intake temperature of 60°C, and the number of rotations of the rotor was Under conditions of 300 rpm and an exhaust temperature of 37 to 42°C, 500 parts by weight of the above-mentioned aqueous glucose solution was sprayed to obtain glucose granules (third granules) having an average particle diameter of 450 μm. To the mixture of 315 parts by weight of glucose particles and the first and second particles, 42.0 parts by weight of acetic acid was added and mixed in a V-type mixer to produce the formulation of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com