Low-temperature water-phase preparation method for porous gold nanocrystals

A water-phase preparation and gold nanotechnology, which is applied in metal processing equipment, transportation and packaging, etc., to achieve high activity, reduce preparation costs, and increase physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, pour a mixed solution of 0.33ml of 0.74mol / L sodium citrate and 0.165ml of 1.2mol / L sodium carbonate and 5ml of deionized water into a beaker, and place it in an ice-water mixed water bath at 0°C for magnetic stirring for 1 hour;

[0031] Then, drop 0.33ml0.68mol / L of chloroauric acid and continue to stir for 4h. The solution was golden yellow in the first two hours without any change. After two hours, the solution began to gradually turn black from golden yellow. The color of the solution gradually deepens, and the whole process is carried out in a water bath environment mixed with ice and water at 0°C;

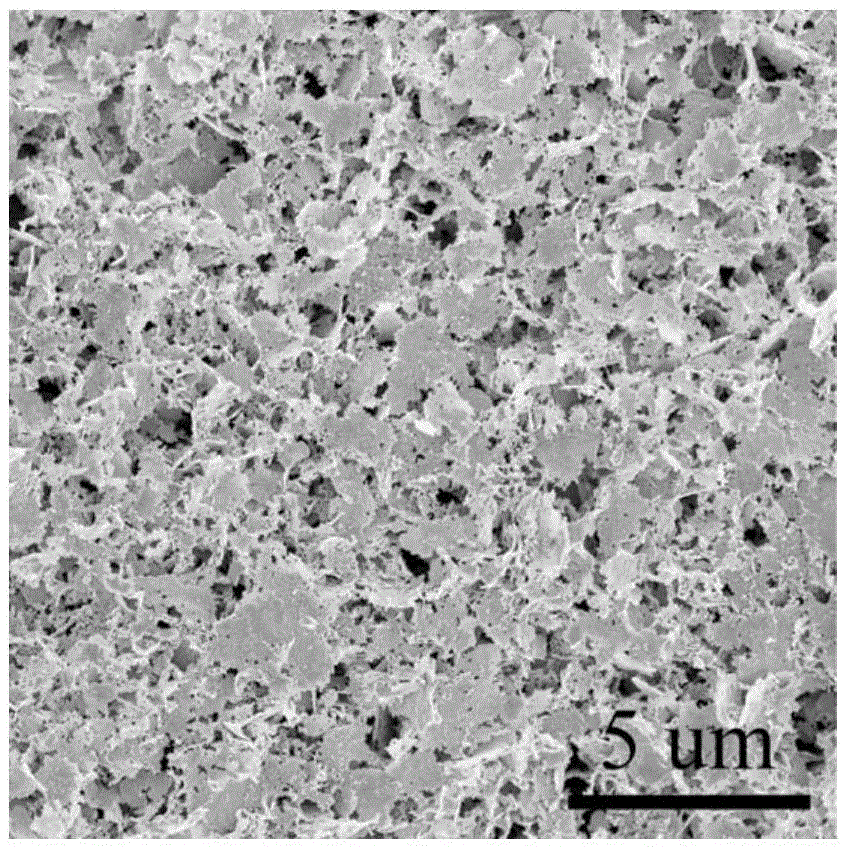

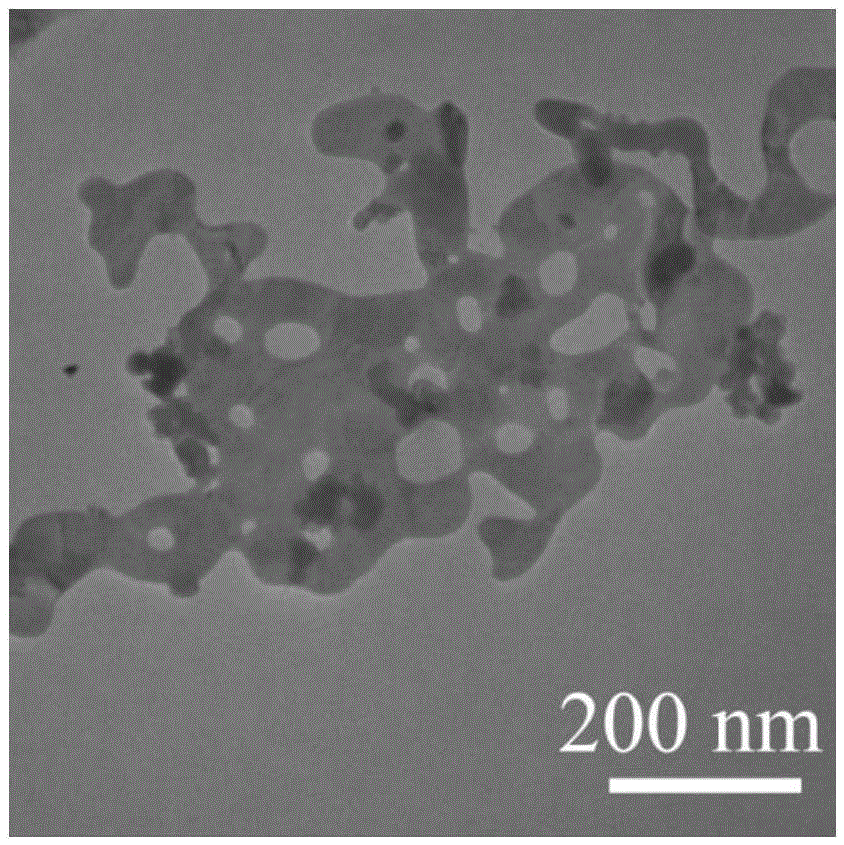

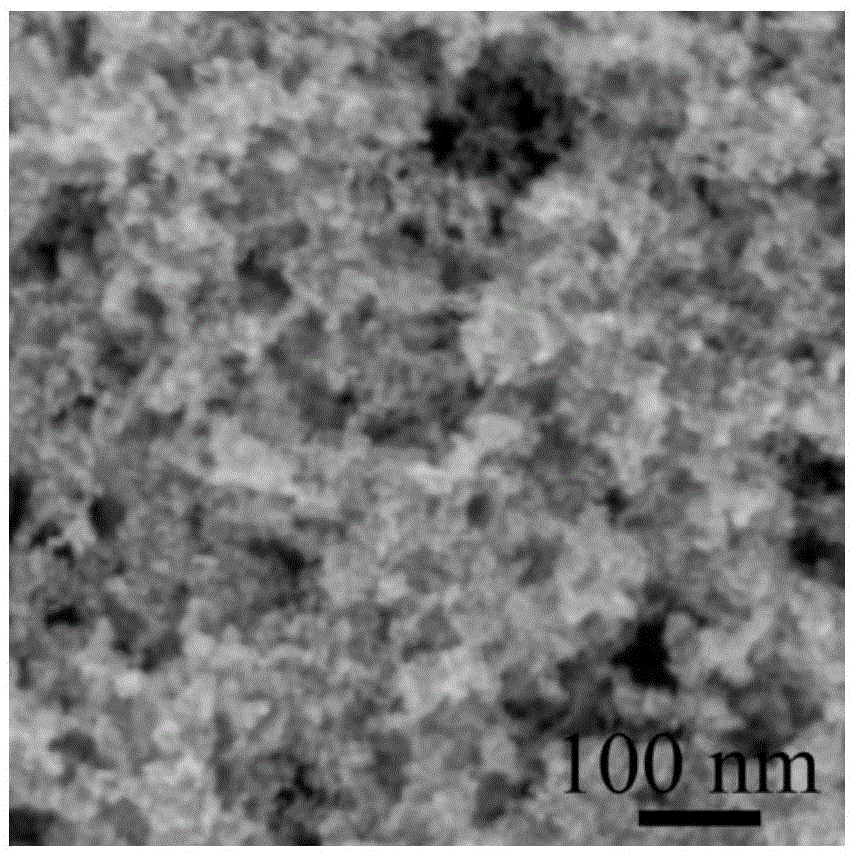

[0032] Finally, it was placed in an ice-water mixed water bath environment at 0°C for precipitation for 30 hours, centrifuged and washed at room temperature to obtain porous gold nanocrystals. like figure 1 and figure 2 Shown are field emission scanning electron micrographs and transmission electron micrographs of porous gold nanocrystals, respectively.

Embodiment 2

[0034] First, pour a mixed buffer solution of 0.33ml of 0.74mol / L sodium citrate and 0.165ml of 1.2mol / L sodium carbonate and 5ml of deionized water into a beaker, and place it in an ice-water mixed water bath at 0°C for 1 hour with magnetic stirring ;

[0035] Then, drop 0.33ml0.68mol / L of chloroauric acid and continue to stir for 4h. The solution was golden yellow in the first two hours without any change. After two hours, the solution began to gradually turn black from golden yellow. The color of the solution gradually deepens, and the whole process is carried out in a water bath environment mixed with ice and water at 0°C;

[0036] Finally, put it in a 0°C ice-water mixed water bath environment for 72 hours, and make full use of effective kinetic control to achieve effective control of the shape of gold nanocrystals, so that the gold nanocrystals can be transformed from gold nanoparticles to porous gold nanocrystals. Transition to multiple morphologies of sheet-like nonpo...

Embodiment 3

[0038] First, add 0.33ml0.74mol / L sodium citrate to each of the five beakers, then add 0.33ml1.2mol / L sodium carbonate solution, 0.25ml1.2mol / L sodium carbonate solution, 0.16ml1.2mol / L sodium citrate L of sodium carbonate solution, 0.08ml of 1.2mol / L sodium carbonate solution, 0ml of 1.2mol / L sodium carbonate solution (that is, no sodium carbonate solution), then add 5ml of deionized water respectively, and place in ice water at 0°C Magnetic stirring in a mixed water bath environment for 1h;

[0039] Then, drop respectively the chloroauric acid of 0.33ml0.68mol / L in 5 beakers, continue magnetic stirring 4 hours;

[0040] Finally, the samples were placed in an ice-water mixed water bath at 0°C for 4 hours, centrifuged and washed at room temperature to obtain gold nanocrystals with different shapes. When the amount of sodium carbonate solution used is 0.33ml, gold nanoparticles with smaller size will be formed; when the amount of sodium carbonate solution used is 0ml and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com