Preparation method of selenium-tellurium alloy semiconductor micro-wire

A selenium-tellurium alloy and semiconductor technology, which is applied in the field of preparation of selenium-tellurium alloy semiconductor micron wires, can solve the problems of difficult control conditions, unfavorable environment, complicated process, etc., and achieve the effects of wide applicability, low environmental pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. high-purity selenium powder (Se x Te 1-x (x=1)) tightly packed into a phosphate glass tube closed at one end, the outer diameter of the glass tube is 23mm, the inner diameter is 3mm, and the length is 80mm. After vacuuming, then seal the other end of the glass tube well.

[0024] b. The assembled fiber preform is drawn on a drawing tower at a drawing temperature of 620°C. The drawn selenium fiber has an outer diameter of 600 μm, a core diameter of 350 μm, and a length of tens of centimeters.

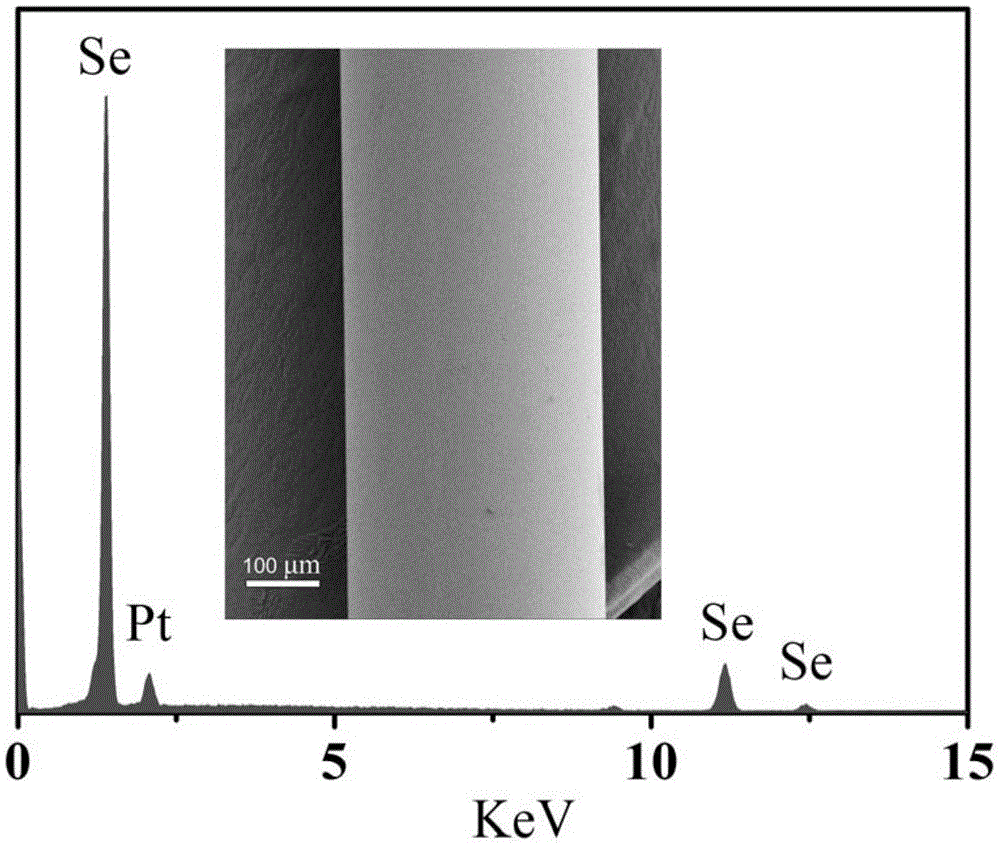

[0025] c. Soak the selenium fiber in a mixed acid solution with a concentration of 35% HF and 10% HCl for 4 hours, heat it in a water bath at 40°C, then ultrasonicate, separate, and wash to obtain ultra-long micron wires of selenium semiconductors. figure 1 It is the EDS map of the selected area of the selenium semiconductor micron wire. The spectrum shows that the micron wire is pure selenium element, and the characteristic peak of Pt element is due to the spraying of Pt ...

Embodiment 2

[0027] a. High-purity tellurium powder (Se x Te 1-x (x=0)) tightly packed into a phosphate glass tube with one end closed, the outer diameter of the glass tube is 25mm, the inner diameter is 3.2mm, and the length is 100mm. After vacuuming, then seal the other end of the glass tube well.

[0028] b. The assembled fiber preform is drawn on a drawing tower at a drawing temperature of 650°C. The drawn tellurium fiber has an outer diameter of 300 μm, a core diameter of 45 μm, and a length of tens of centimeters.

[0029] c. Soak the tellurium fiber in a mixed acid solution with a concentration of 35% HF and 10% HCl for 5 hours, heat it in a water bath at 40°C, then ultrasonicate, separate, and clean, and finally obtain a tellurium semiconductor ultra-long micron wire.

Embodiment 3

[0031] a. the high-purity selenium powder and tellurium powder in a molar ratio of 4:1 (Se x Te 1-x (x=0.8)) mixed evenly, and then tightly filled into a phosphate glass tube with one end closed, the outer diameter of the glass tube is 20mm, the inner diameter is 3mm, and the length is 80mm. After vacuuming, then seal the other end of the glass tube well.

[0032] b. The assembled fiber preform is drawn on a drawing tower at a drawing temperature of 630°C. The drawn selenium-tellurium alloy semiconductor fiber has a diameter of 350 μm, a core diameter of 80 μm, and a length of tens of centimeters.

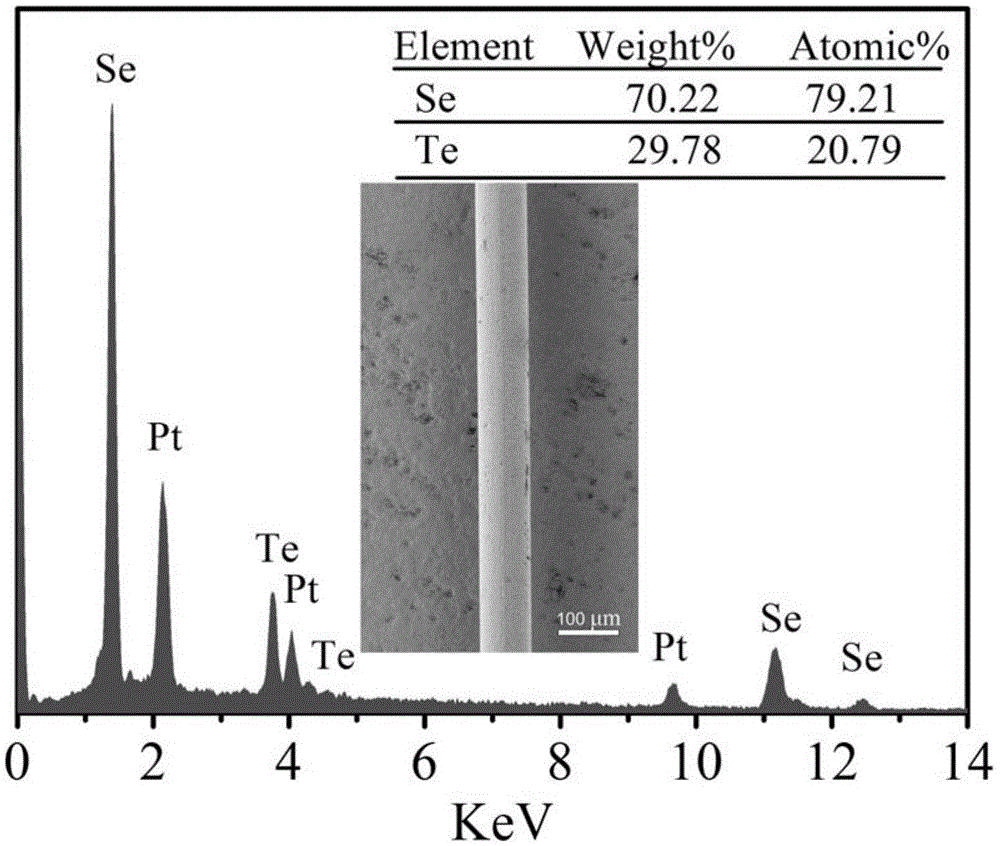

[0033] c. Soak selenium-tellurium alloy semiconductor fibers in a mixed acid solution of 35% HF and 10% HCl for 4.5 hours, heat in a water bath at 40°C, then ultrasonically, separate, and clean, and finally obtain ultra-long micron wires of selenium-tellurium alloy semiconductors. image 3 Is Se 0.8 Te 0.2 The EDS map of the selected area on the surface of the alloy semiconducto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com