High-performance aluminosilicate glass primarily made from red mud and preparation method of high-performance aluminosilicate glass

An aluminosilicate glass, high-performance technology, applied in the field of materials, can solve problems such as poor water resistance and acid resistance, achieve the effect of low density and reduce industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

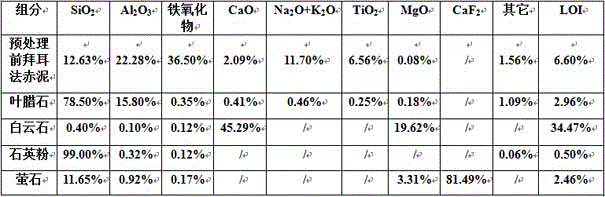

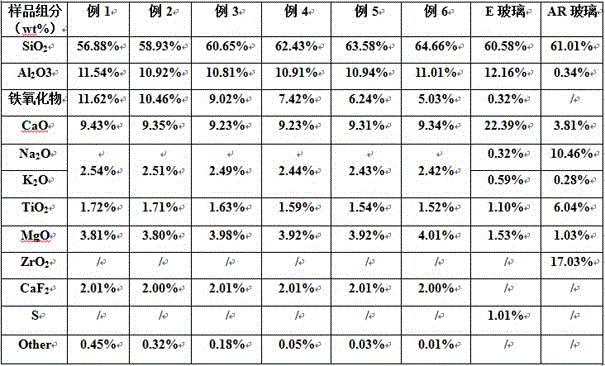

[0031] In the following examples, the components of Bayer process red mud, pyrophyllite, dolomite, quartz powder and fluorite before pretreatment used in the preparation of high-performance aluminosilicate glass are shown in Table 1 (wt%).

[0032] Except for the red mud, the raw materials of the present invention come from industrial raw materials, and no special treatment is required. The red mud used in the present invention belongs to the Bayer method red mud, and the red mud needs to be pretreated before use. The method is to place the Bayer method red mud in an oven at 110°C for 24 hours to eliminate the moisture in the red mud and dry the red mud powder Pass through a 200 mesh sieve. Then mix the ingredients according to Table 1 and place them evenly in the lifting electric furnace, and melt them at 1500°C for 6-7 hours, including the process of clarification and homogenization. Anneal at 450°C for 2 hours to eliminate the residual stress inside the glass, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com