A method for adsorbing and separating lutein by using ultra-high cross-linked resin

An ultra-high cross-linked resin, adsorption separation technology, applied in the biological field, can solve the problems of difficult separation of lutein and low yield, and achieve the effects of reducing waste water discharge, high adsorption capacity, and high adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

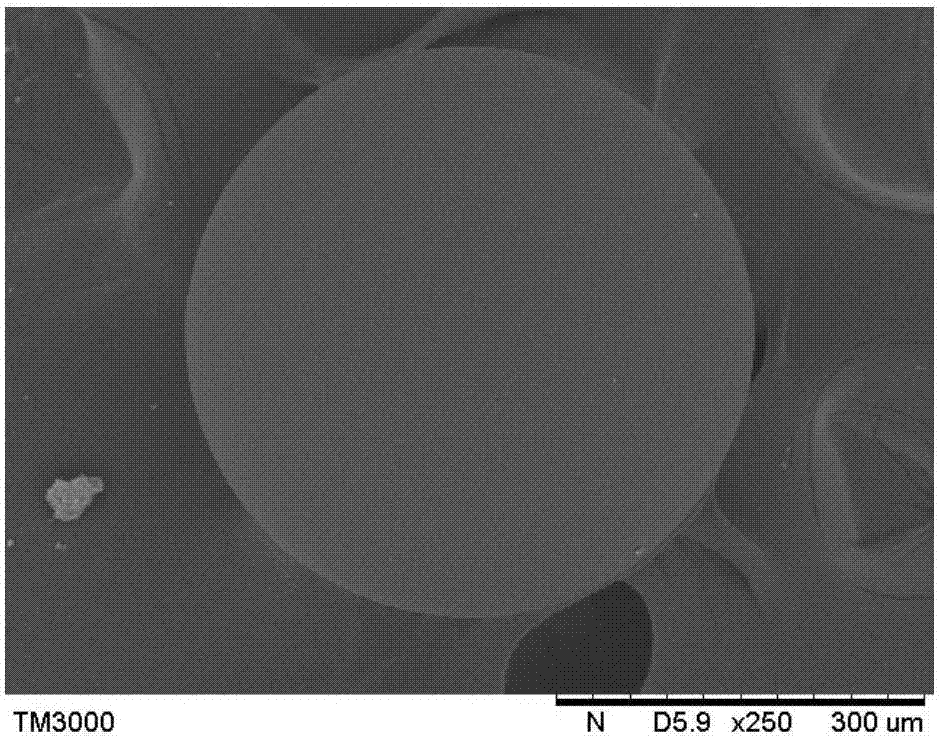

[0041] Fully swell 5g of chloromethylstyrene-divinylbenzene resin in 50mL of dichloroethane, add 0.25g of Fourier catalyst AlCl 3 , mechanically stirred and mixed for 0.5h, and the temperature was raised to 75°C at a rate of 1°C / min, and the Friedel-Crafts reaction was carried out for 2h. Rinse alternately until the filtrate is colorless, add 25 mL of acetic anhydride to the washed resin, and react at a temperature of 35° C. After the reaction, vacuum dry to obtain the desired resin. The obtained product was in the form of light brown round granules. The average particle size is 0.45-0.55mm, the water content is 39wt%, the pore size is 1.85nm, the porosity is 25%-35%, and the wet density is 1.08g / cm 3 , the average specific surface area is 875.12m 2 / g, average pore volume 0.755cm 3 / g, the functional group is carbonyl. like figure 1 , the prepared resin was scanned by a scanning electron microscope, and it could be observed that the inner diameter of the resin was 0.465 ...

Embodiment 2

[0045] Fully swell 10g of chloromethylstyrene-divinylbenzene resin in 90mL of dichloroethane, add 0.36g of Fourier catalyst AlCl 3 , mechanically stirred and mixed for 1 hour, the temperature was raised to 100 degrees Celsius at a rate of 2 degrees Celsius / min, and the Friedel-Crafts reaction was carried out for 2.5 hours. Rinse until the filtrate is colorless, add 65 mL of acetic anhydride to the washed resin, and react at a temperature of 45° C. After the reaction, vacuum dry to obtain the desired resin. The obtained product is in the form of light brown round particles, with an average particle size of 0.35-0.65mm, a water content of 40wt%, a pore size of 1.77nm, a porosity of 28%-31%, and a wet density of 1.11g / cm 3 , the average specific surface area is 768.15m 2 / g, average pore volume 0.633cm 3 / g, the functional group is carbonyl. The particle size distribution of the resin can be obtained by a particle size distribution analyzer, such as figure 2 It can be observ...

Embodiment 3

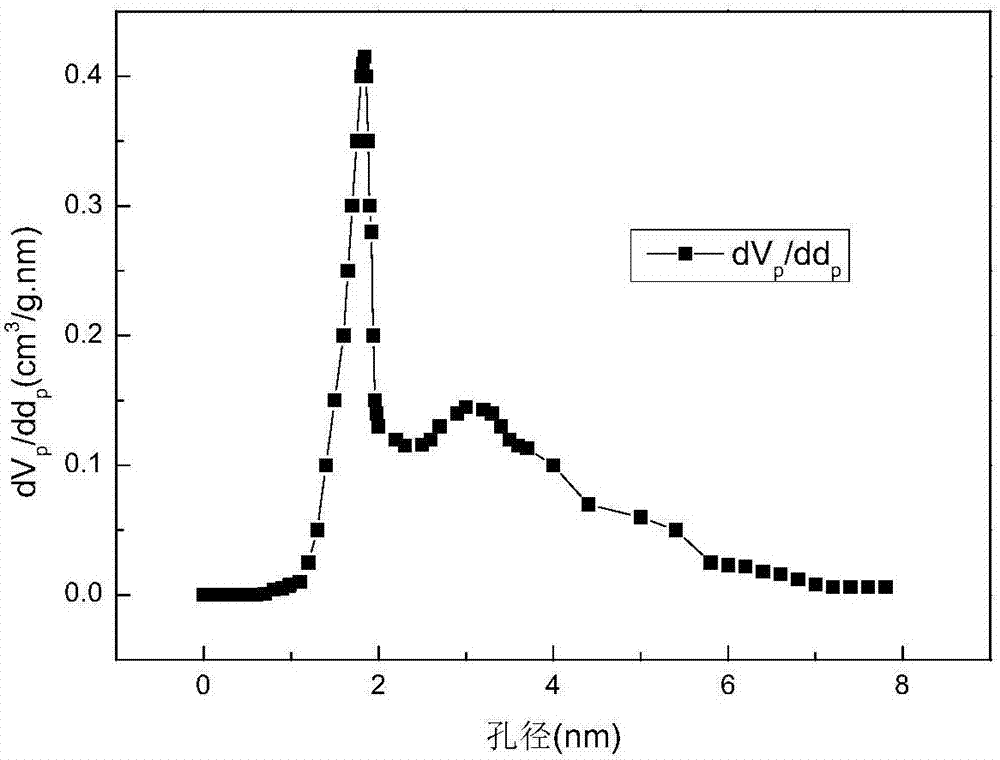

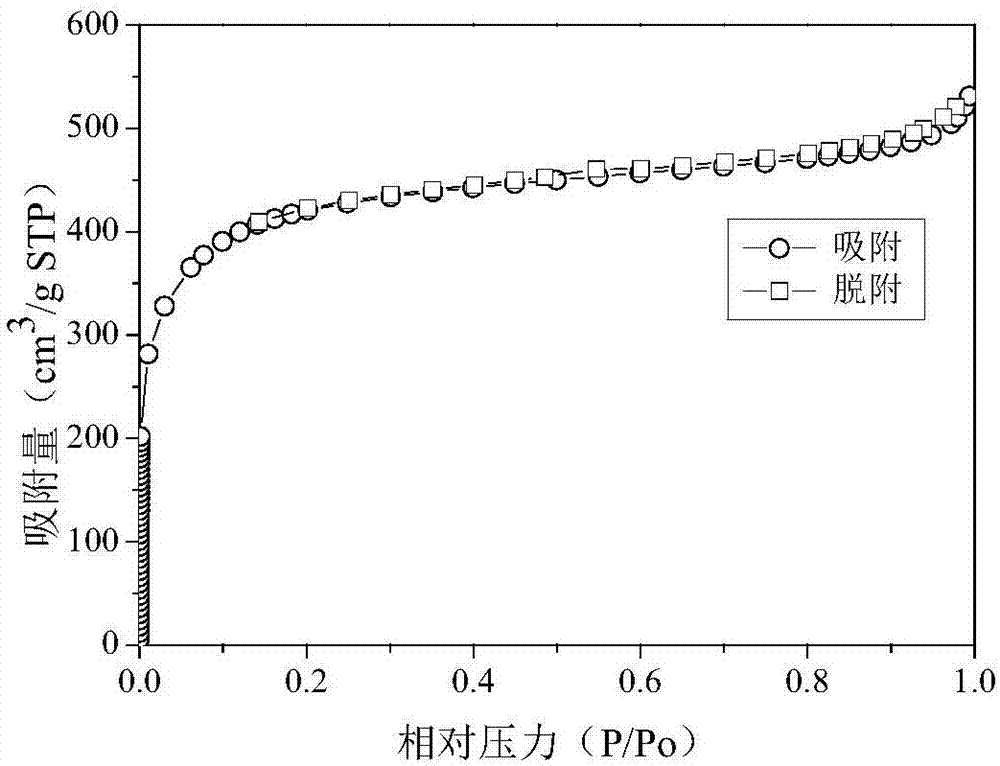

[0049] Fully swell 10g of chloromethylstyrene-divinylbenzene resin in 110mL of dichloroethane, add 0.51g of Fourier catalyst AlCl 3 , mechanically stirred and mixed for 1.25h, and the temperature was raised to 111°C at a rate of 1.5°C / min, and the Friedel-Crafts reaction was carried out for 4h. Rinse alternately until the filtrate is colorless, add 85 mL of acetic anhydride to the washed resin, and react at a temperature of 55° C. After the reaction, vacuum dry to obtain the desired resin. The obtained product is in the form of light brown round particles, with an average particle size of 0.47-0.56mm, a water content of 43wt%, a pore size of 1.78nm, a porosity of 30%-41%, and a wet density of 1.20g / cm 3 , the average specific surface area is 759.36m 2 / g, average pore volume 0.621cm 3 / g, the functional group is carbonyl. like image 3 As shown in the nitrogen adsorption-desorption isotherm, it shows that the adsorption process of the resin to nitrogen belongs to the monol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com