A kind of preparation method of proanthocyanidin

A technology for thick proanthocyanidins and flower proanthocyanidins, which is applied in the field of preparation of proanthocyanidins, can solve the problem of low purity of extracted products, and achieve the effect of comprehensive utilization and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

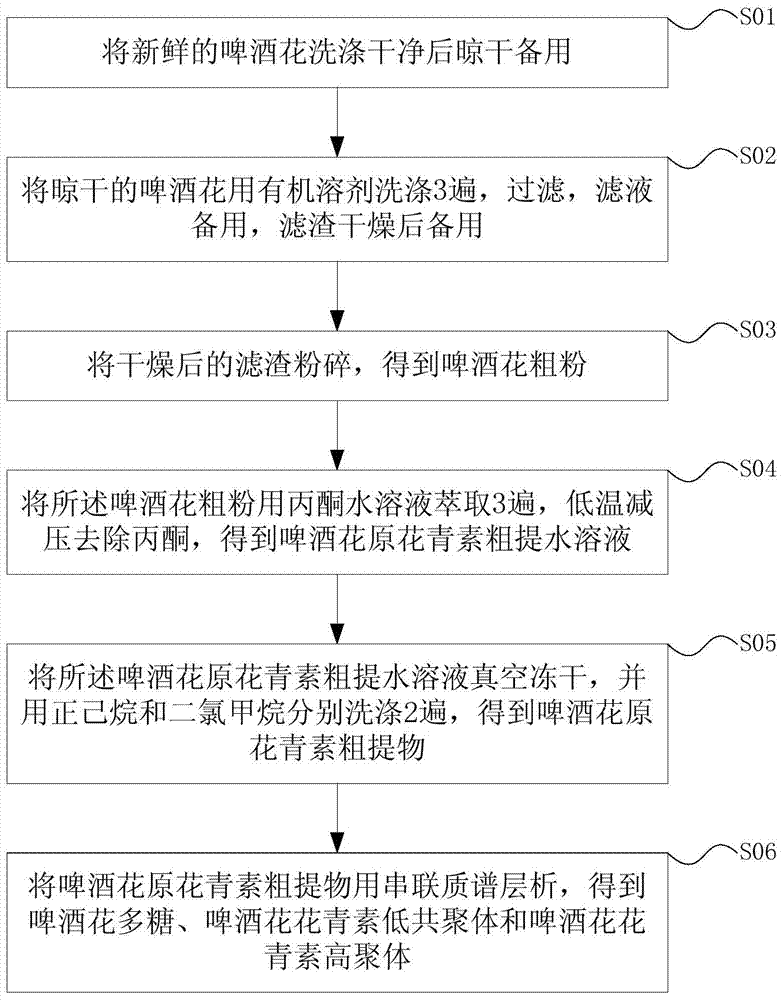

[0029] The preparation method of proanthocyanidins provided by the embodiments of the present invention comprises the following steps:

[0030] S101: washing the fresh hops and drying them for later use;

[0031] S102: washing the dried hops three times with an organic solvent, filtering, and using the filtrate for later use, and drying the filter residue for later use;

[0032] S103: pulverize the dried filter residue to obtain coarse hop powder;

[0033] S104: Extract the coarse hop powder with an aqueous acetone solution for 3 times, remove the acetone under reduced pressure at low temperature, and obtain a crude aqueous solution of hop proanthocyanidins;

[0034] S105: Vacuum freeze-dry the aqueous solution of crude hop proanthocyanidins, and wash twice with n-hexane and dichloromethane, respectively, to obtain crude hop proanthocyanidin extracts;

[0035] S106: The hop proanthocyanidin crude extract is chromatographed by tandem mass spectrometry to obtain hop polysaccha...

Embodiment 2

[0037] S201: washing the fresh hops and drying them for later use;

[0038] S202: Wash the dried hops 3 times with an organic solvent whose mass is 50 times the mass of fresh hops, filter, set aside the filtrate, and dry the filter residue for use;

[0039] S203: pulverize the dried filter residue to obtain coarse hop powder;

[0040] S204: Extract the coarse hop powder with an aqueous acetone solution for 3 times, remove the acetone under reduced pressure at low temperature, and obtain a crude aqueous solution of hop proanthocyanidins;

[0041] S205: Vacuum freeze-dry the aqueous solution of crude hop proanthocyanidins, and wash with n-hexane and dichloromethane twice respectively, to obtain crude hop proanthocyanidin extracts;

[0042] S206: The hop proanthocyanidin crude extract is chromatographed by tandem mass spectrometry to obtain hop polysaccharides, hop anthocyanin low copolymers and hop anthocyanin high polymers.

Embodiment 3

[0044] S301: washing the fresh hops and drying them for later use;

[0045] S302: Wash the dried hops 3 times with dichloromethane whose mass is 50 times that of fresh hops, filter, distill the filtrate under reduced pressure, add petroleum ether, filter, wash, and concentrate to obtain a petroleum ether concentrate containing hop chlorophyll, The petroleum ether concentrate containing hop chlorophyll is used for subsequent use, and the filter residue is dried for subsequent use;

[0046] S303: pulverize the dried filter residue to obtain coarse hop powder;

[0047] S304: extracting the coarse hop powder with an aqueous acetone solution for 3 times, removing the acetone under reduced pressure at a low temperature, and obtaining an aqueous solution of crude hop proanthocyanidins;

[0048] S305: Vacuum freeze-dry the aqueous solution of crude hop proanthocyanidins, and wash with n-hexane and dichloromethane twice respectively, to obtain crude hop proanthocyanidin extracts;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com