Erythromycin thiocyanate fermentation broth membrane-process impurity-removing purification process

A technology of high doxycycline and fermentation liquid, applied in the field of pharmaceutical applications, can solve the problems of reducing product quality and yield, low product titer, increasing production cost, etc., so as to improve the quality of concentrated liquid, reduce production cost and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

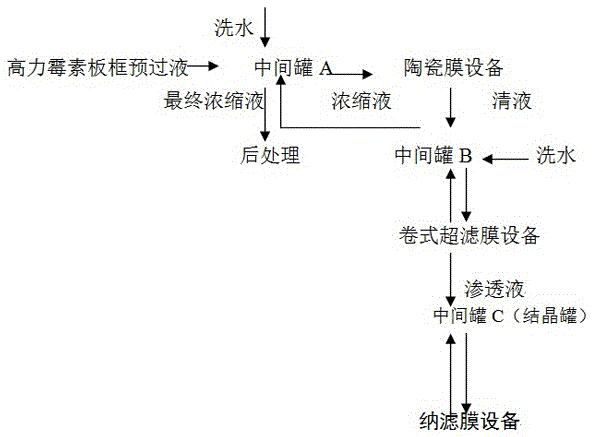

[0019] figure 1 It is the impurity-removing and purifying process of the colomycin fermented liquid membrane method of the specific embodiment of the present invention, and it comprises steps as follows:

[0020] S1: Carry out plate and frame filtration with cololimycin fermented liquid, enter intermediate tank A after filtrate;

[0021] S2: Then use the feeding pump to transport the filtrate to the ceramic membrane separation equipment for concentration, add water and dialyze in batches after concentration to 40%-60%, until the potency U<400 of the concentrate;

[0022] S3: Post-treatment the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com